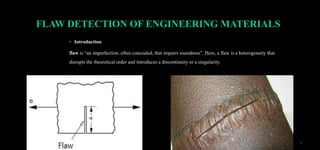

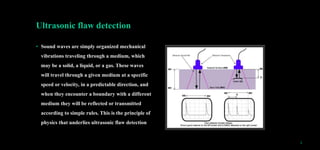

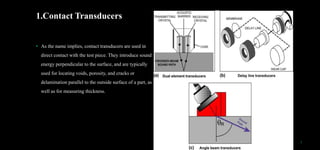

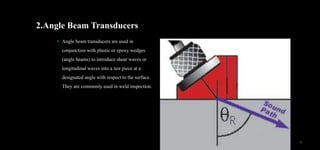

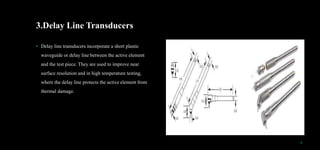

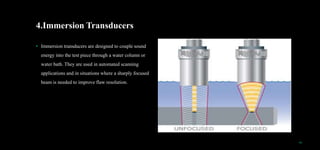

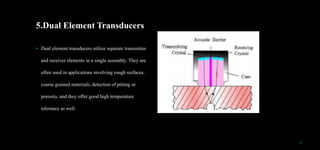

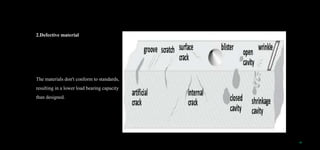

Ultrasonic flaw detection uses sound waves to identify defects in materials. There are various types of ultrasonic transducers that introduce sound waves into a material in different ways. Flaw detectors analyze the ultrasonic waveform to locate and characterize flaws. Structural integrity ensures a structure can support its weight and prevent failure over its lifetime through inspection and maintenance. Determining integrity involves tests like hardness testing and ultrasonic pulse velocity testing to check for cracks or voids. Factors like defective materials, improper design, and unsuitable environmental conditions can lead to structural failure if not addressed.