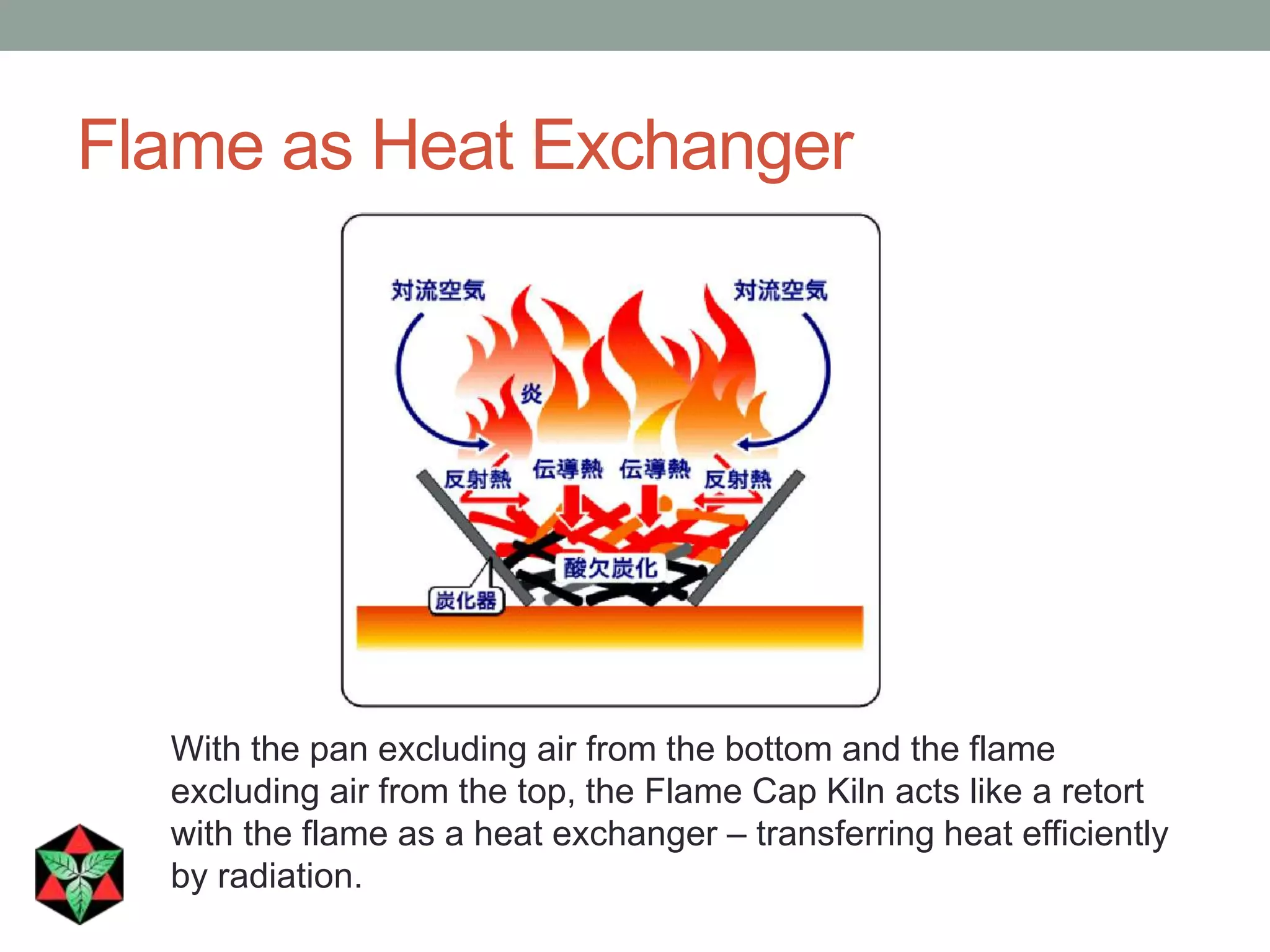

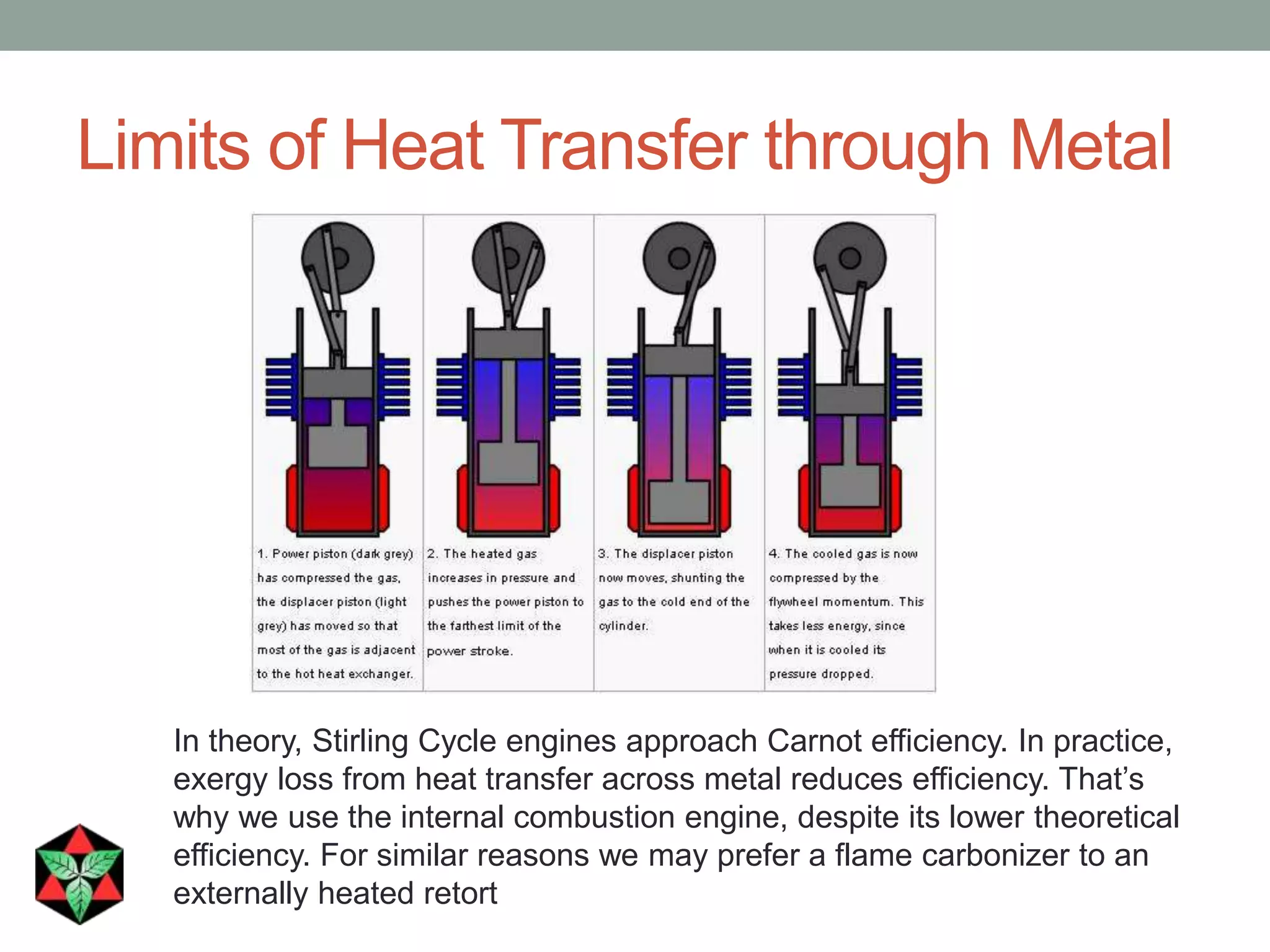

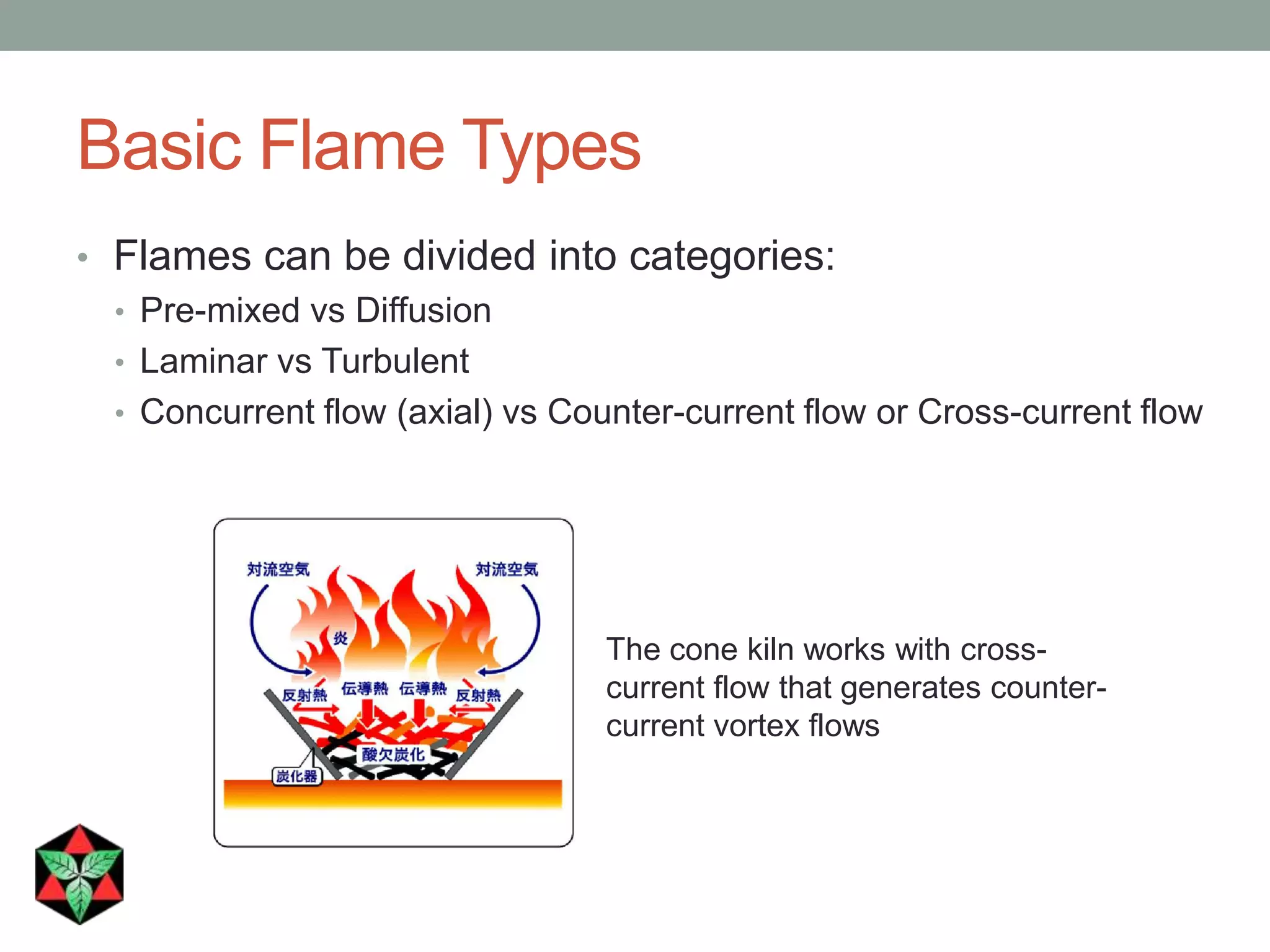

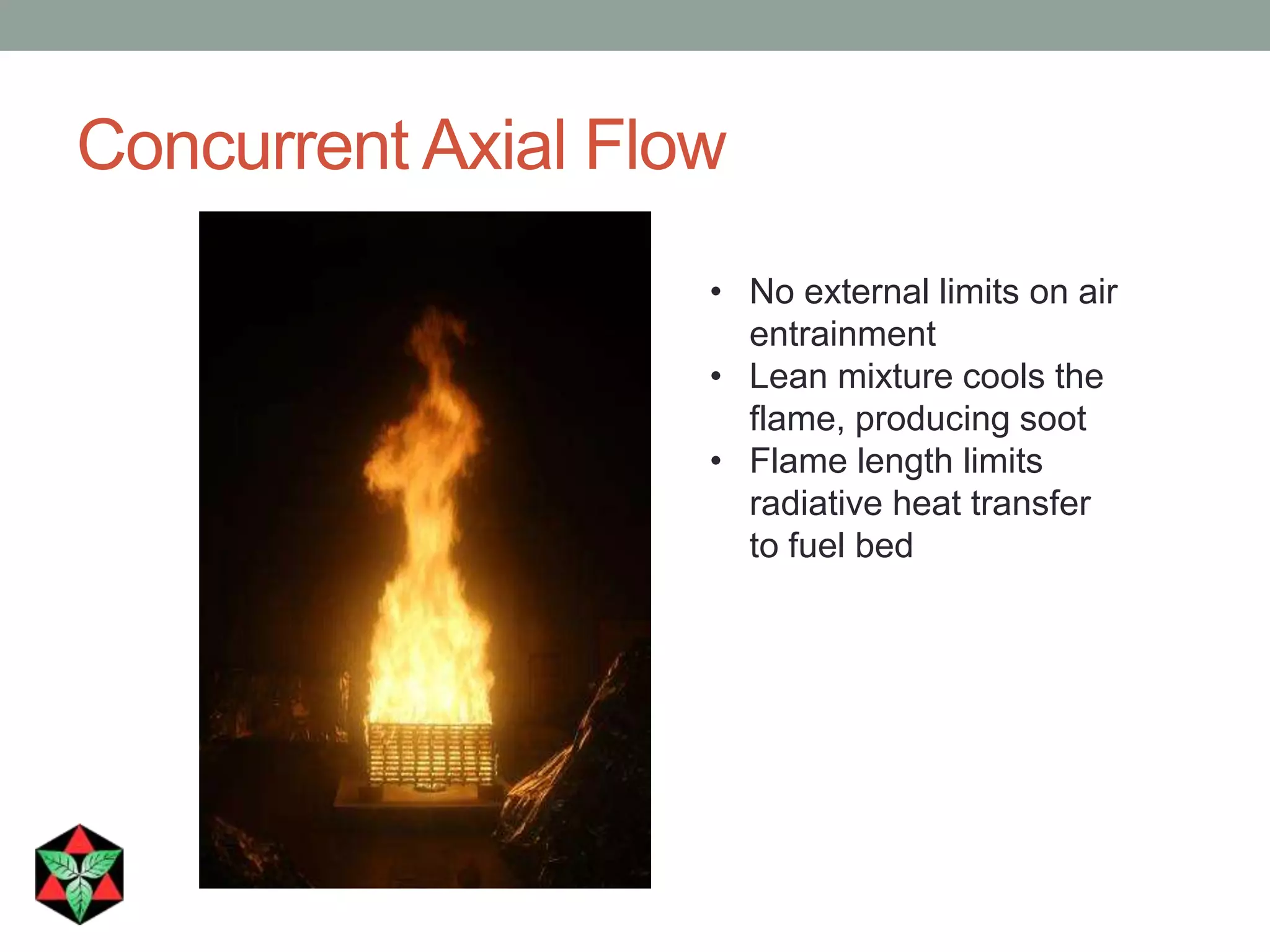

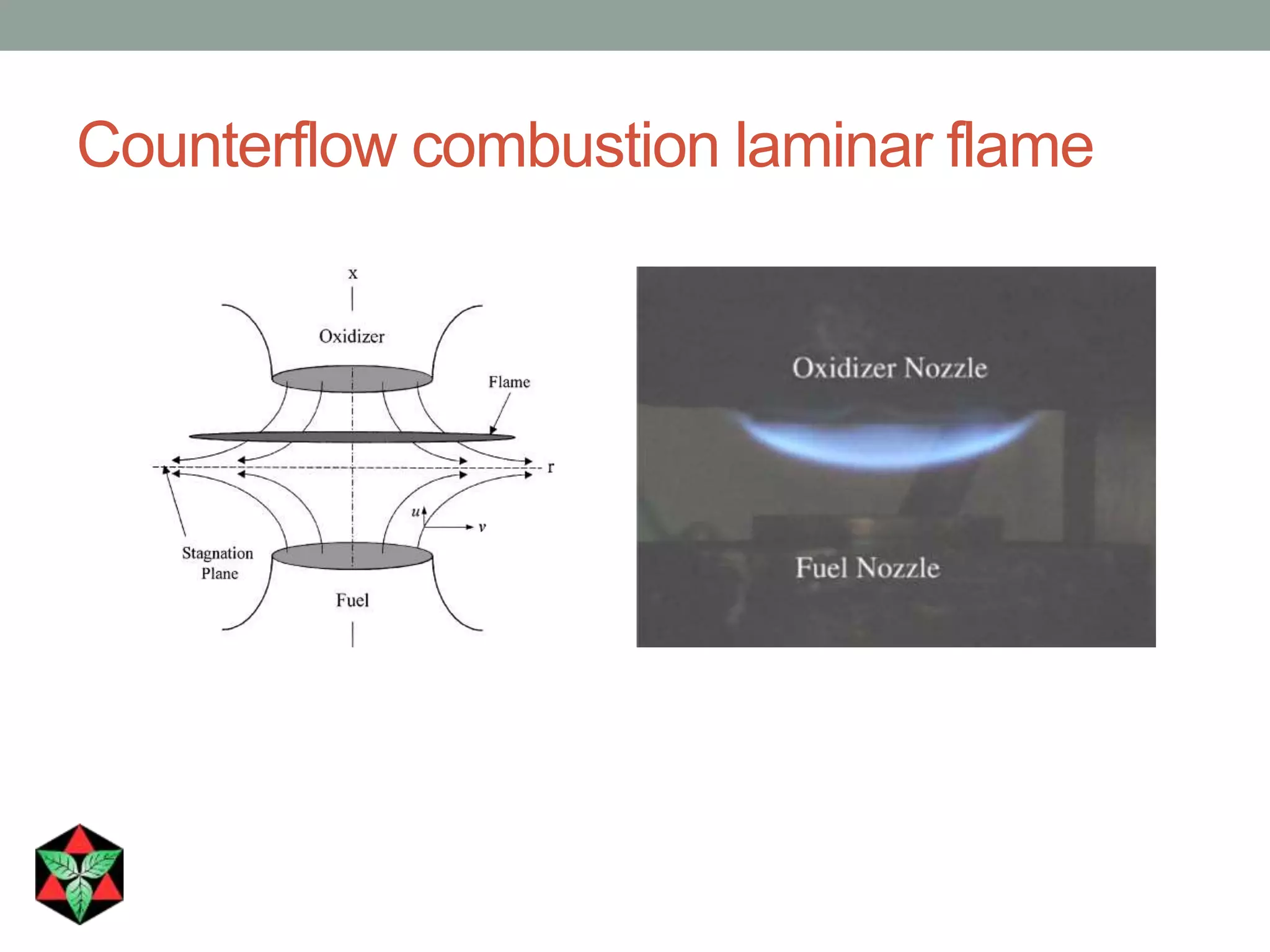

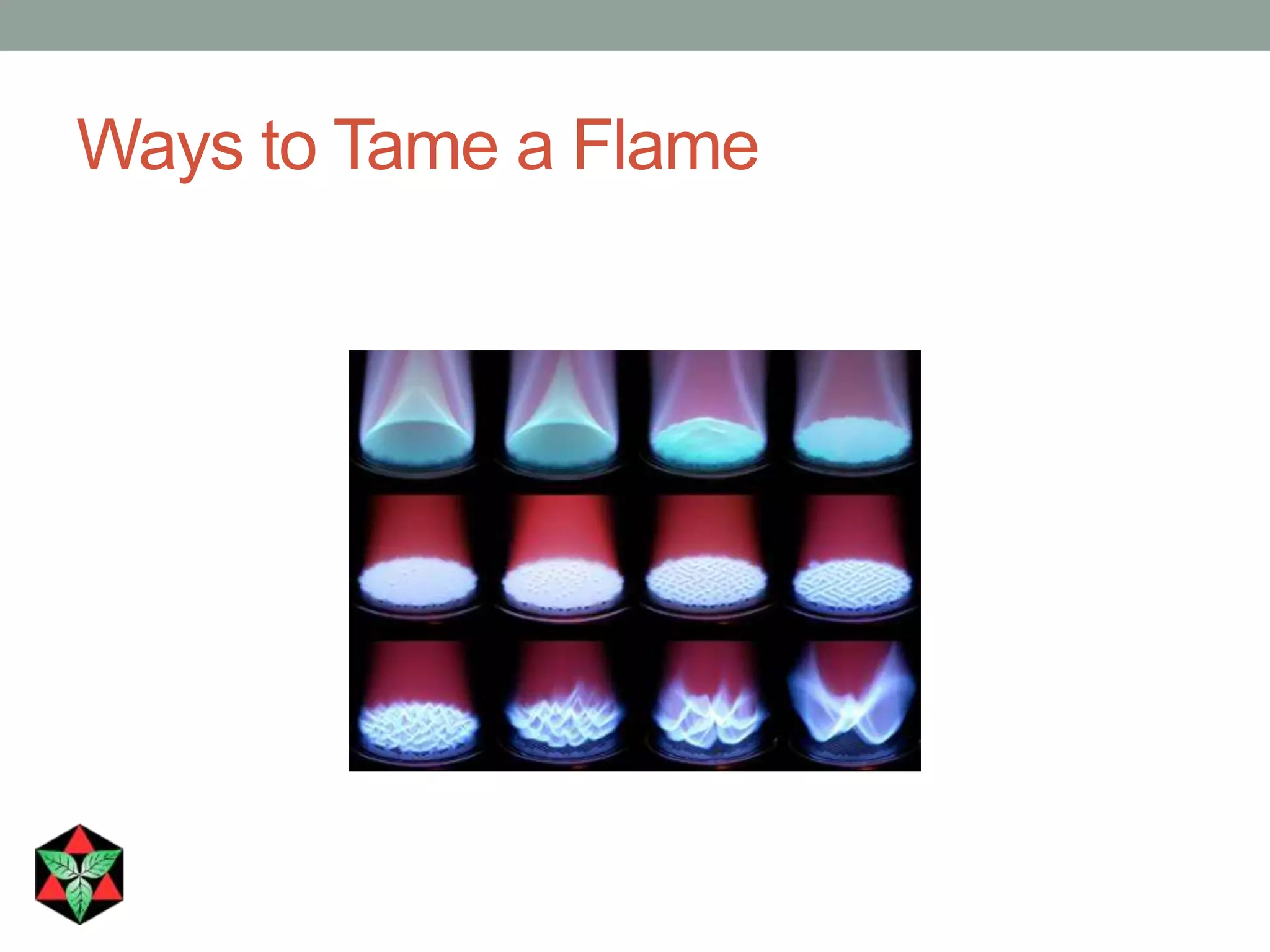

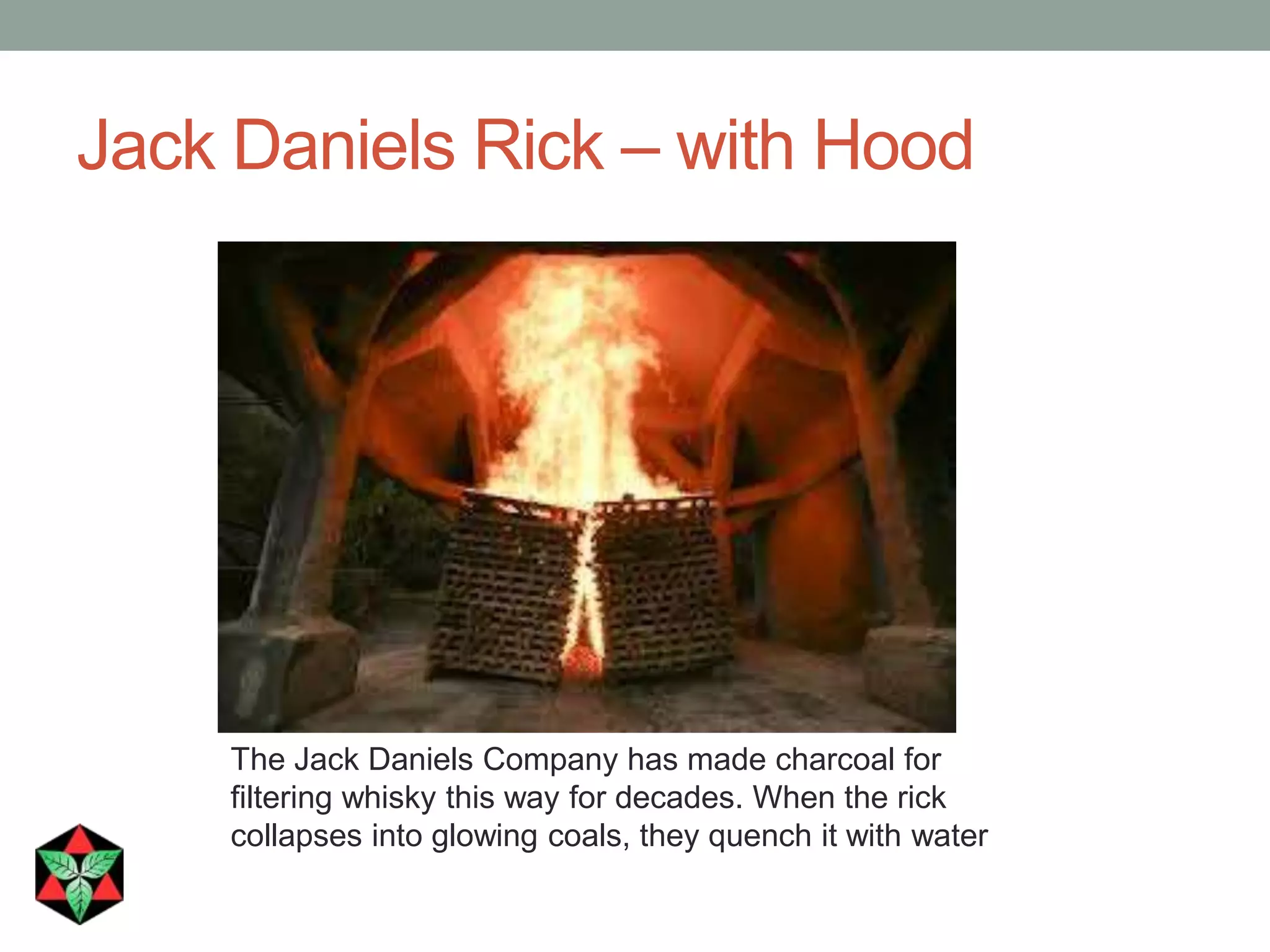

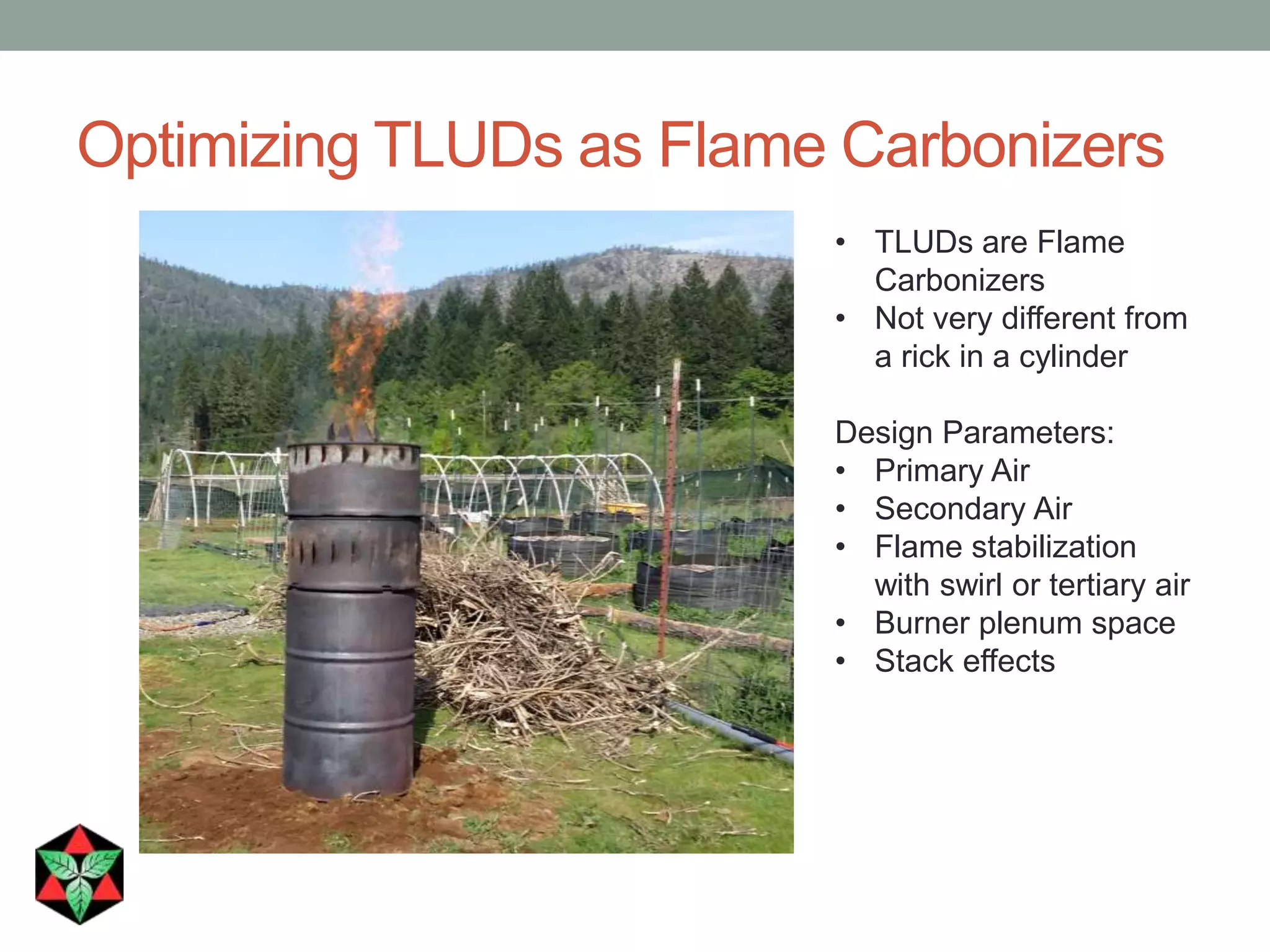

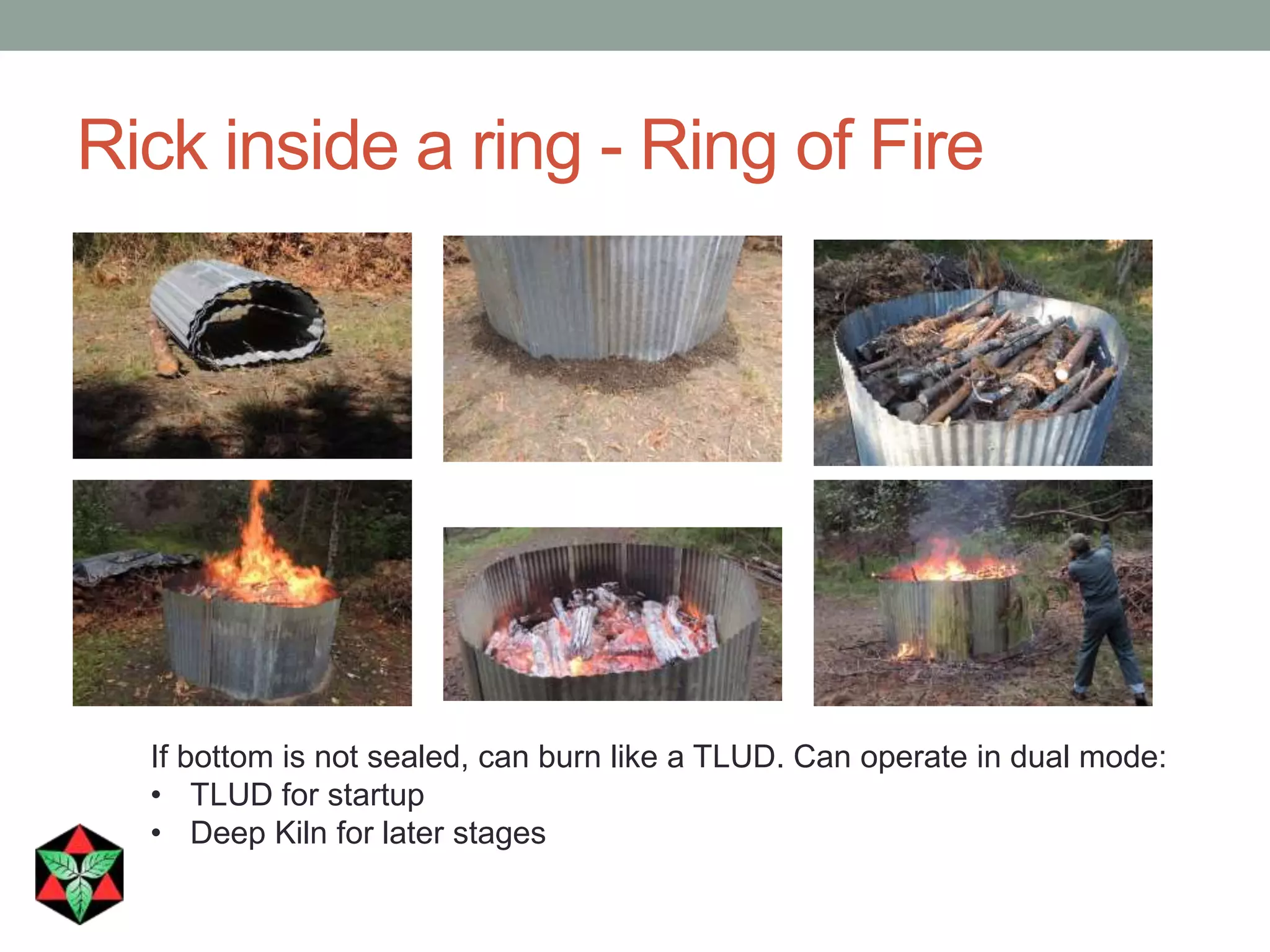

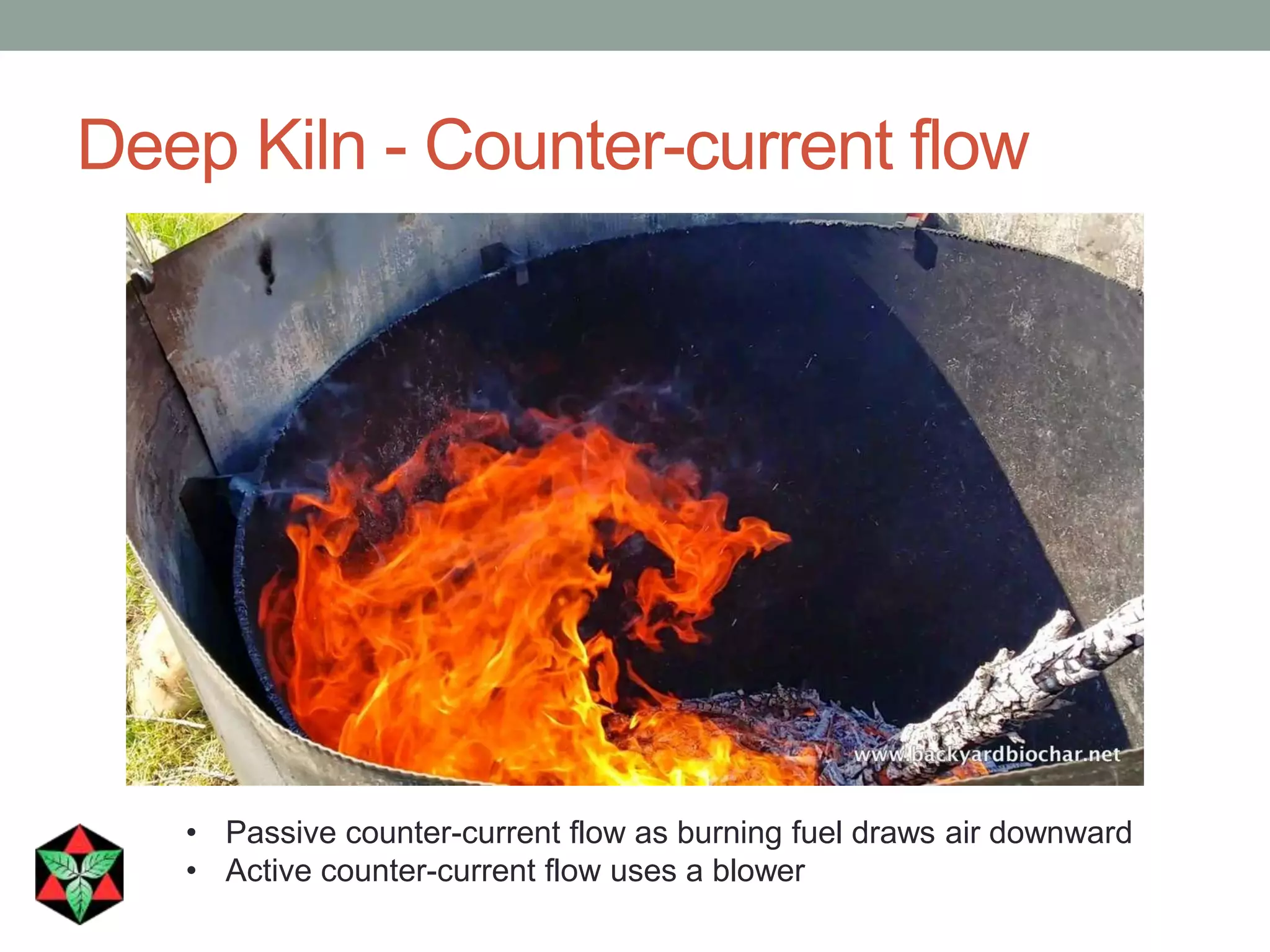

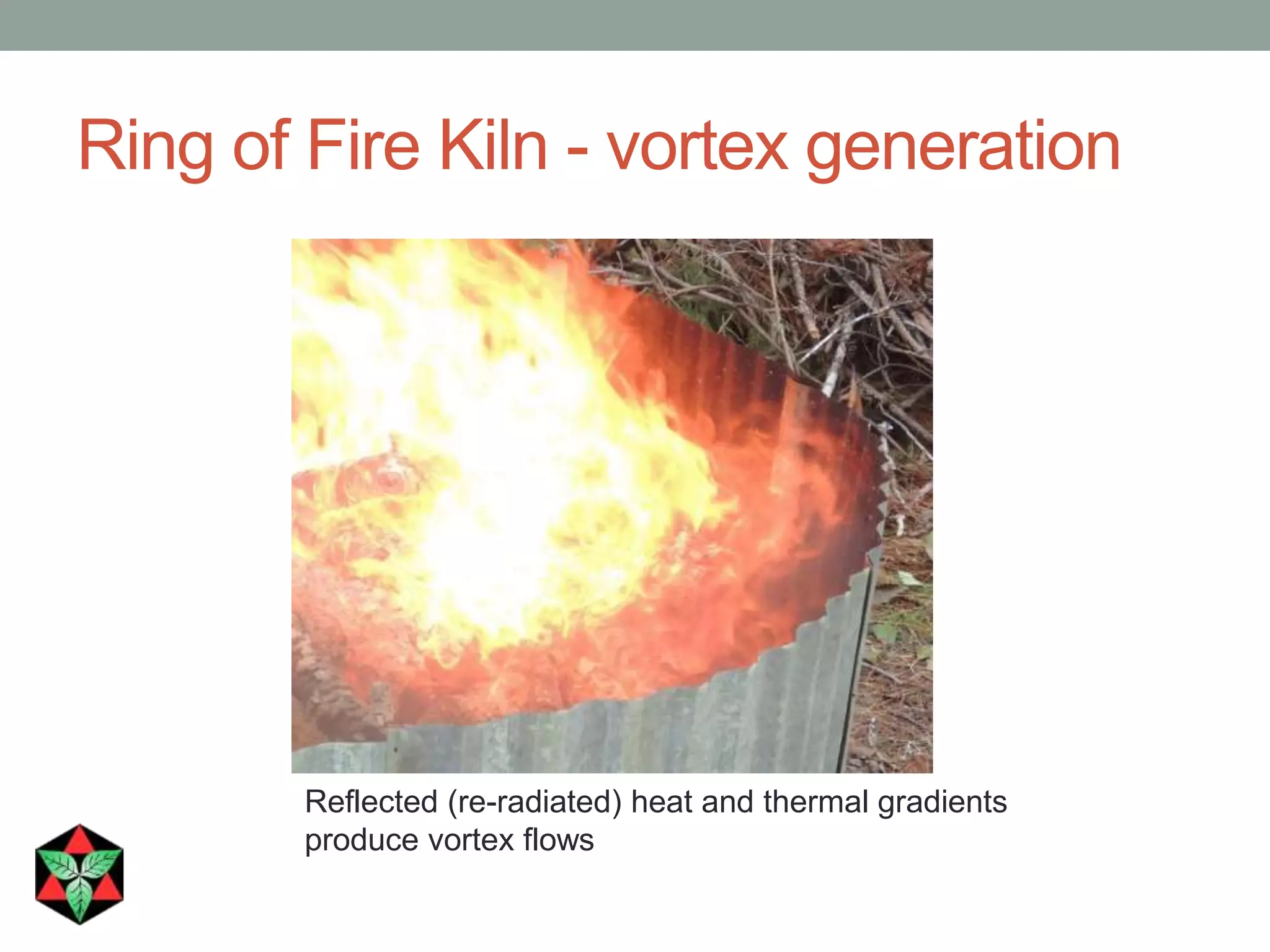

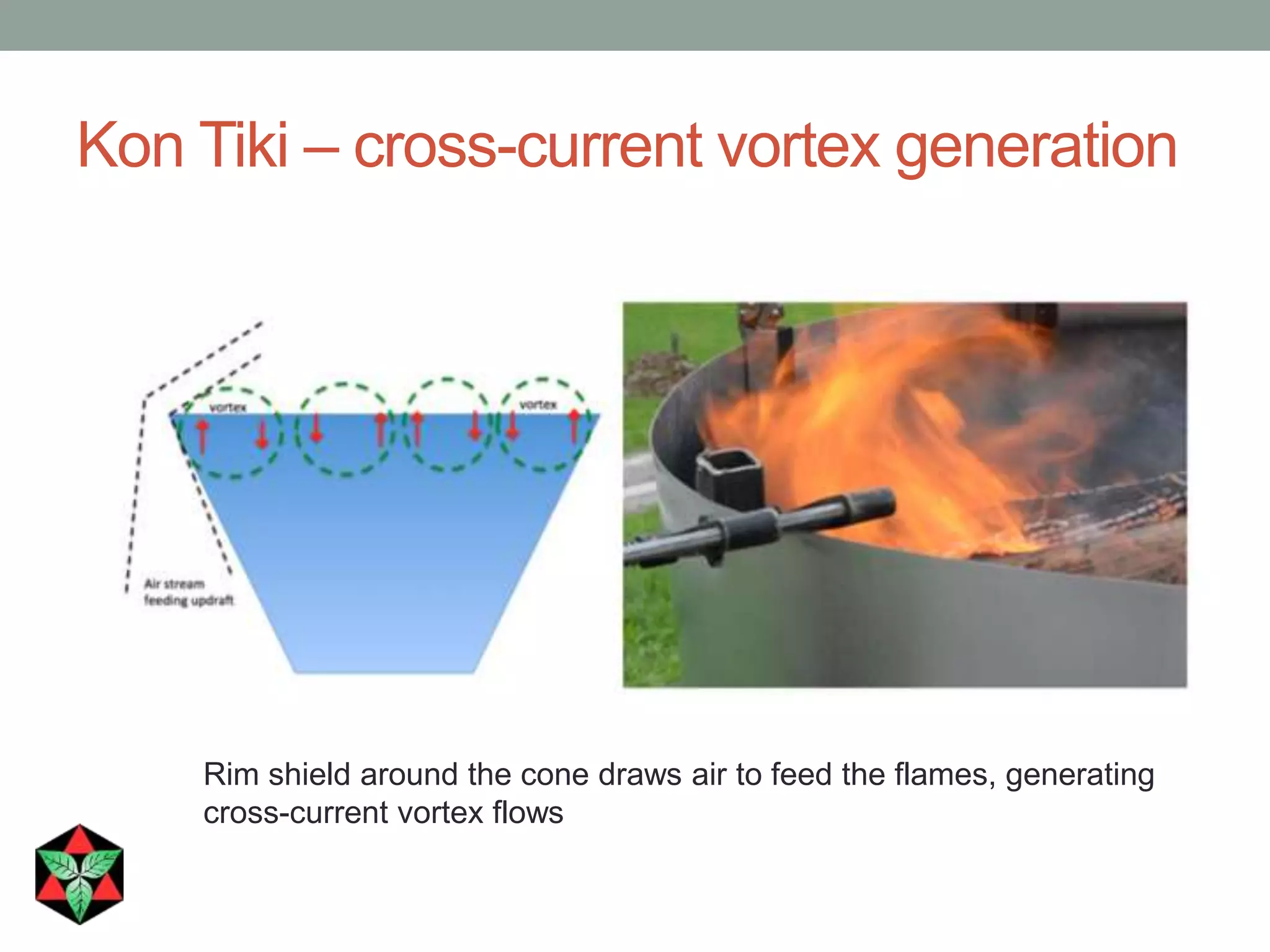

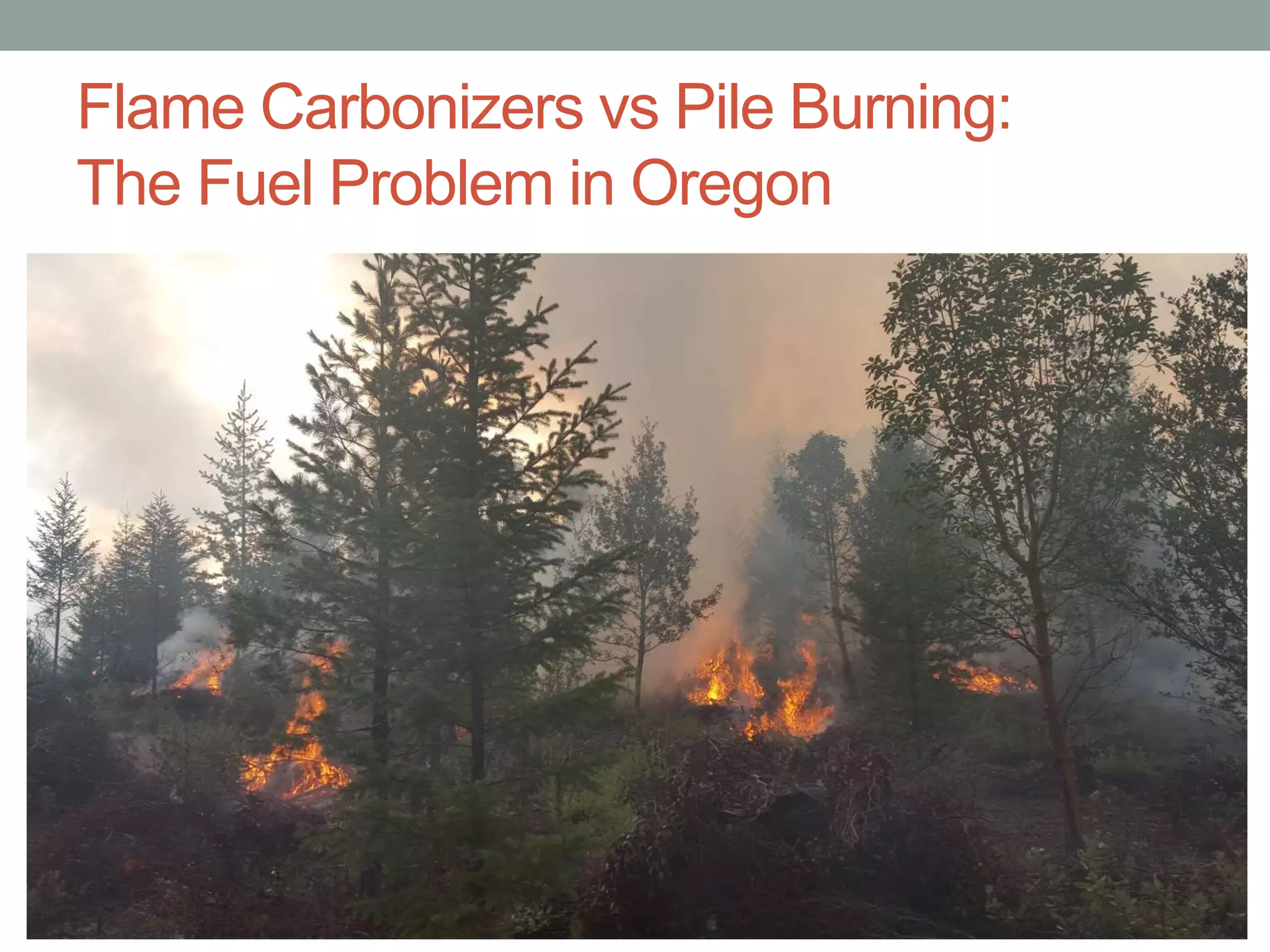

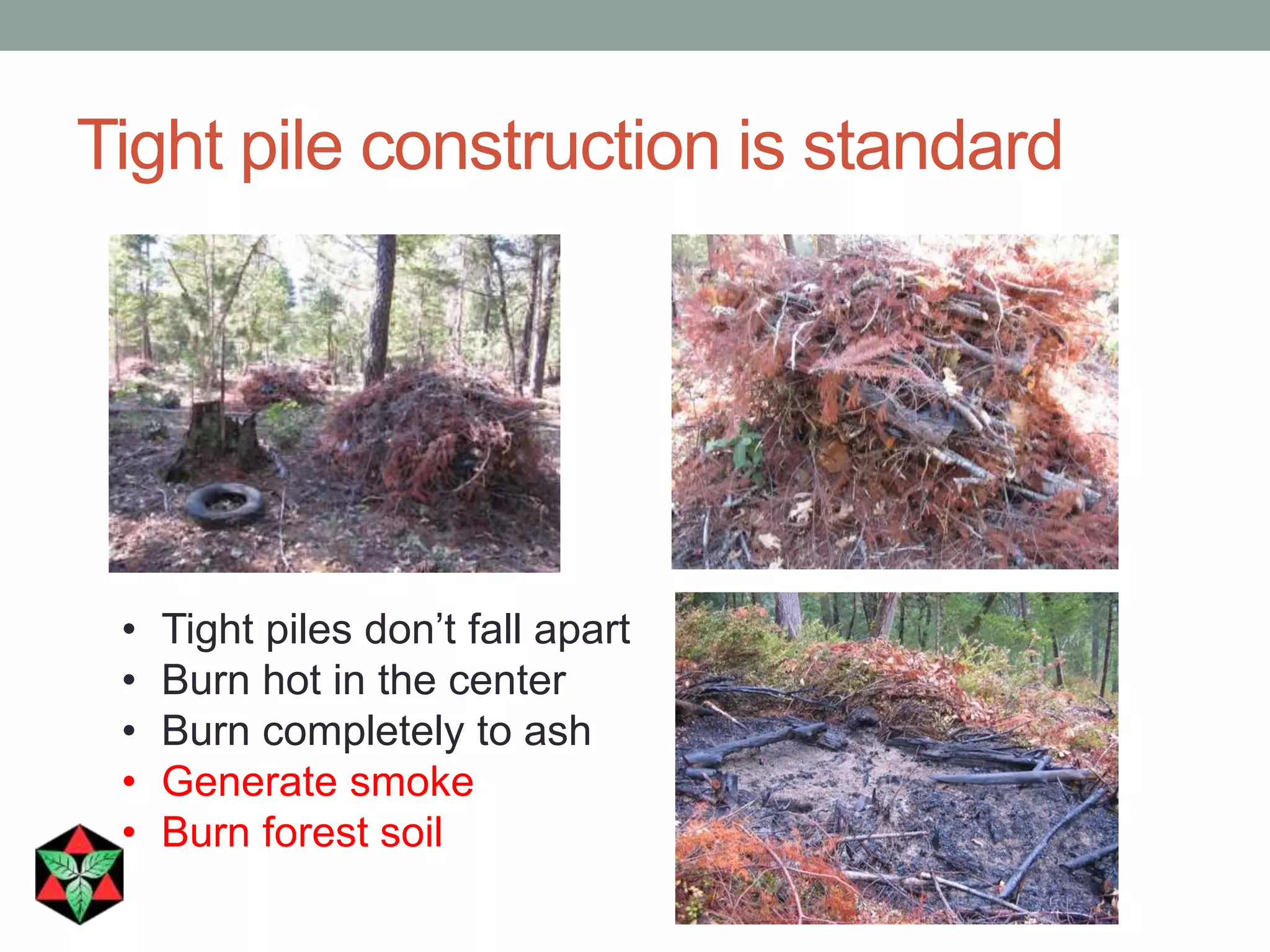

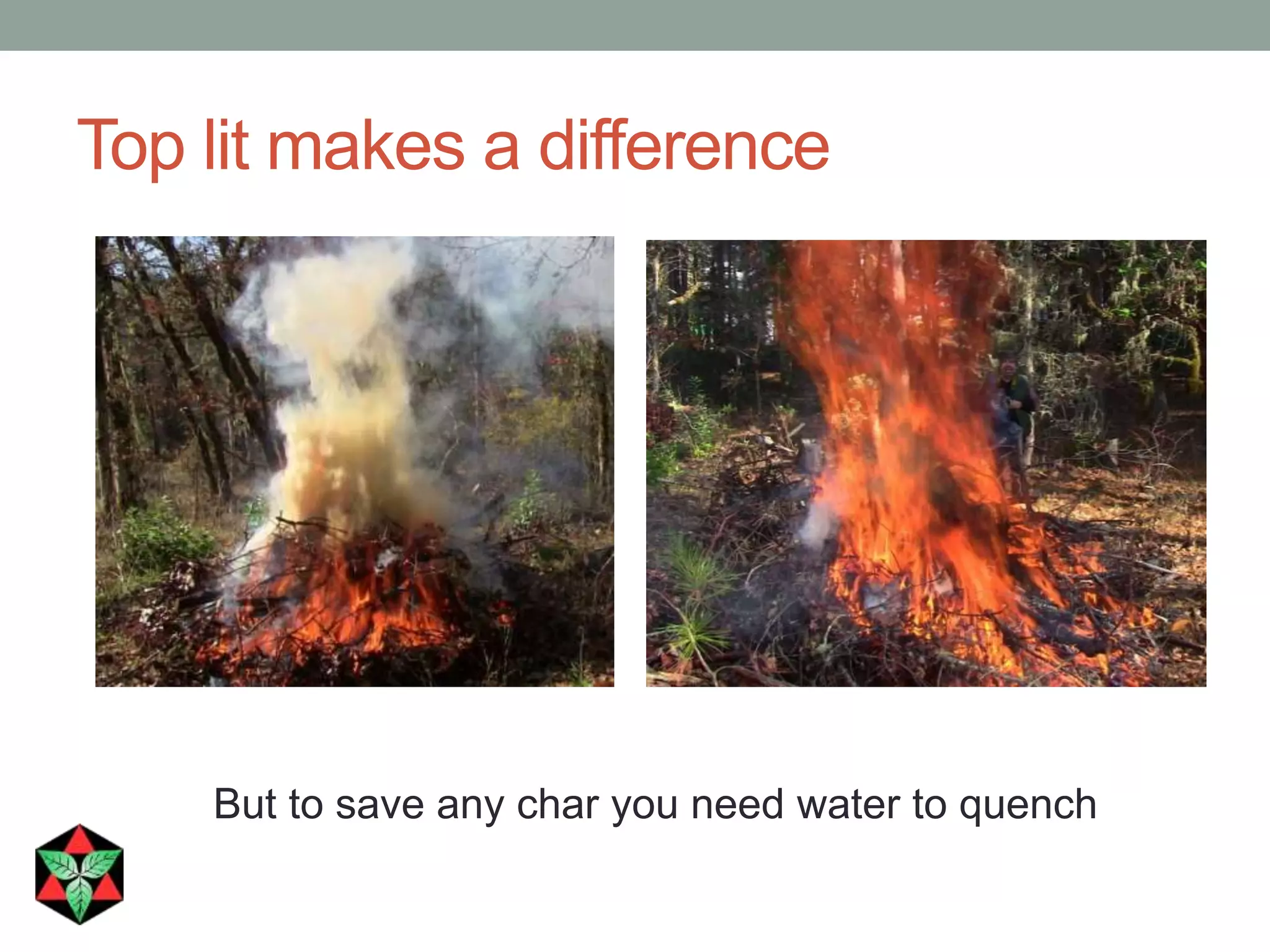

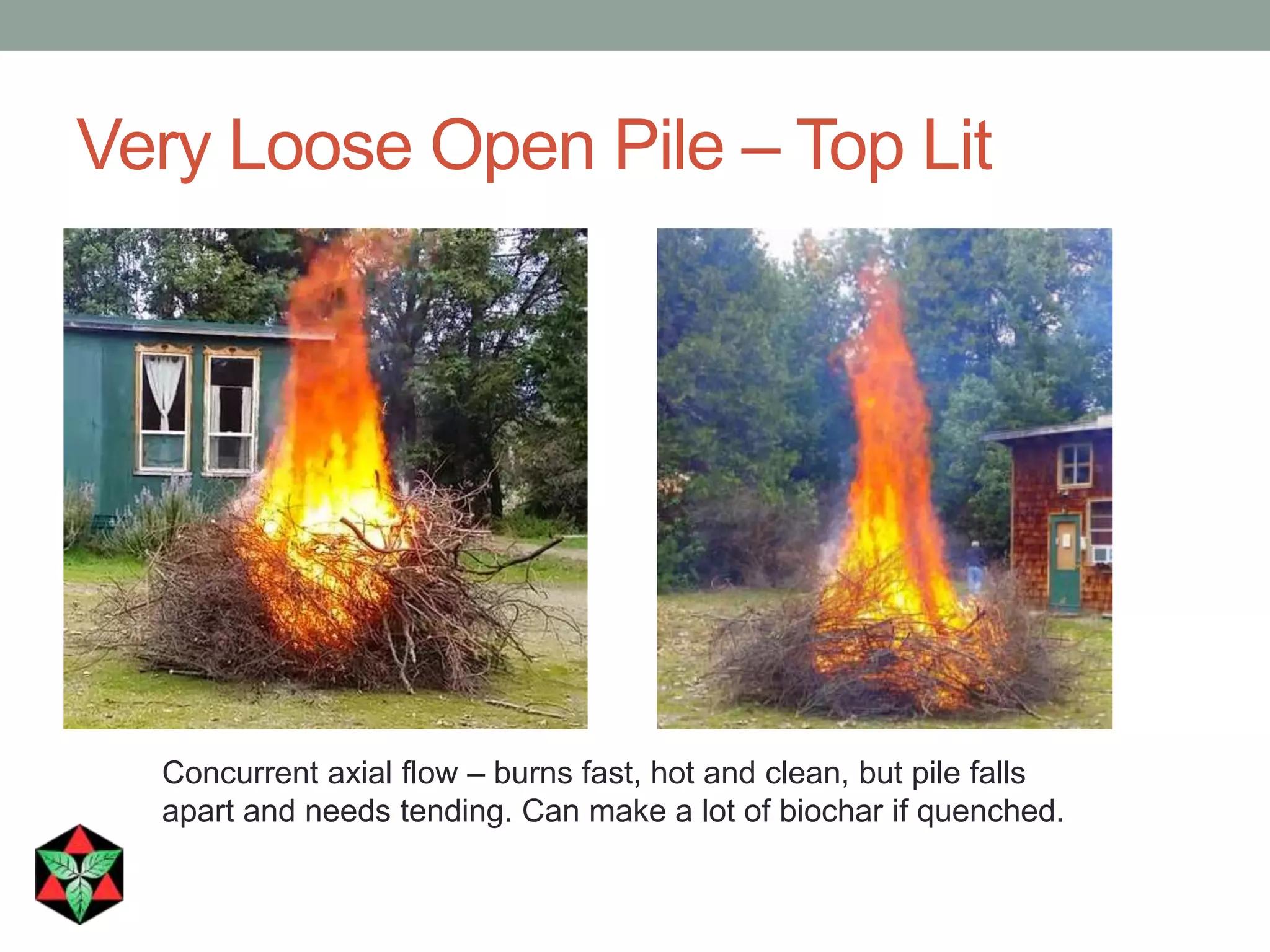

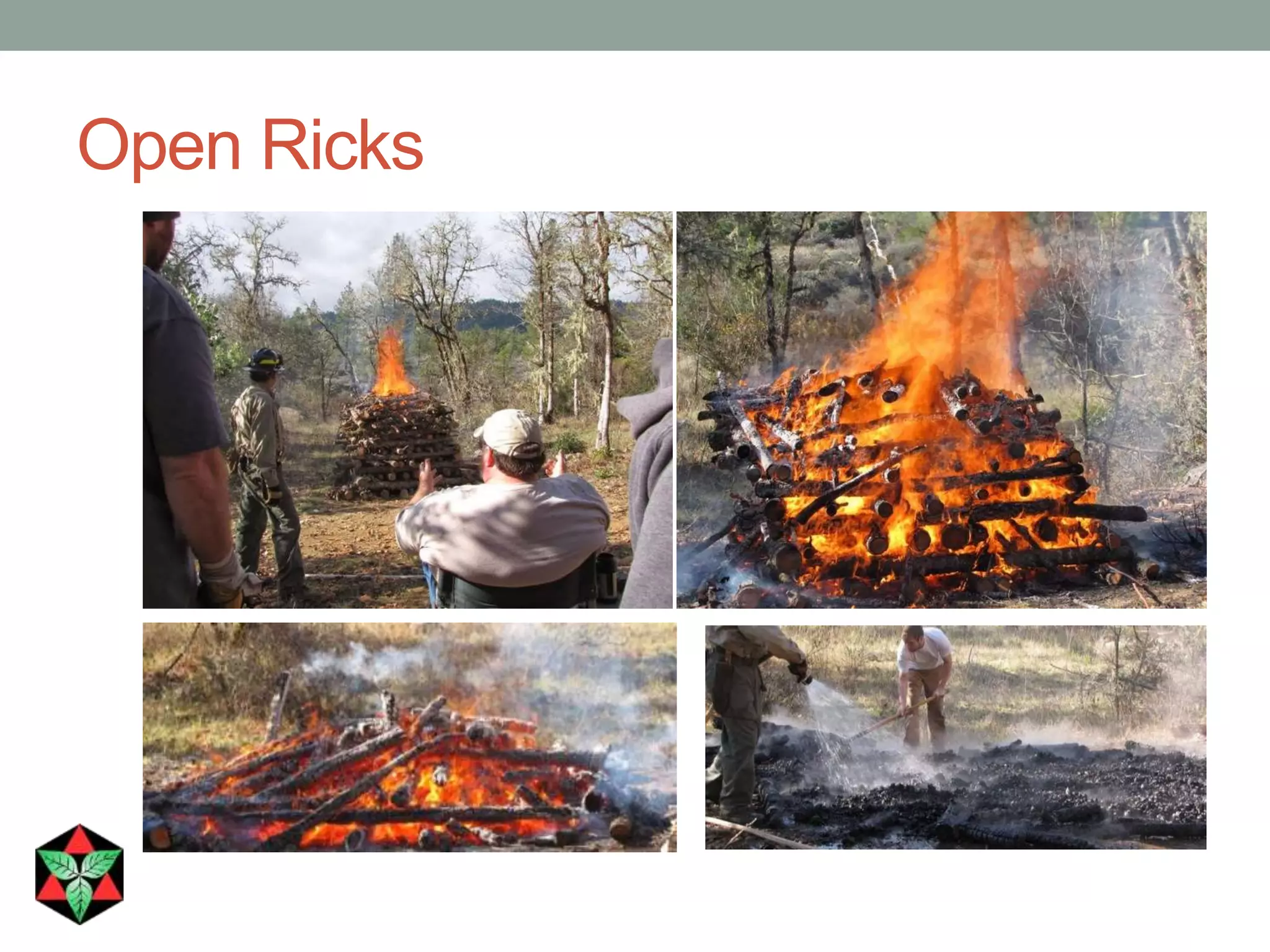

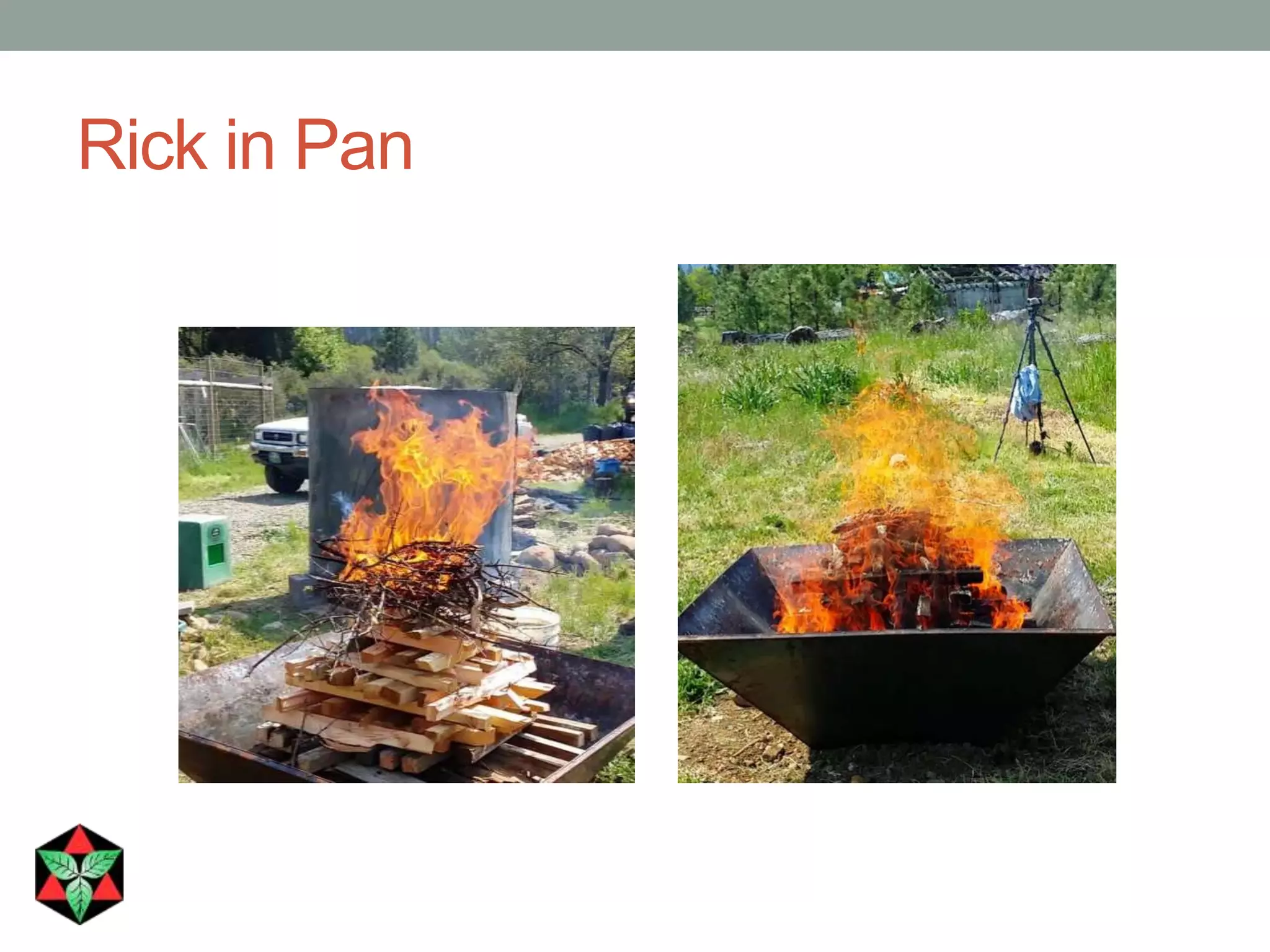

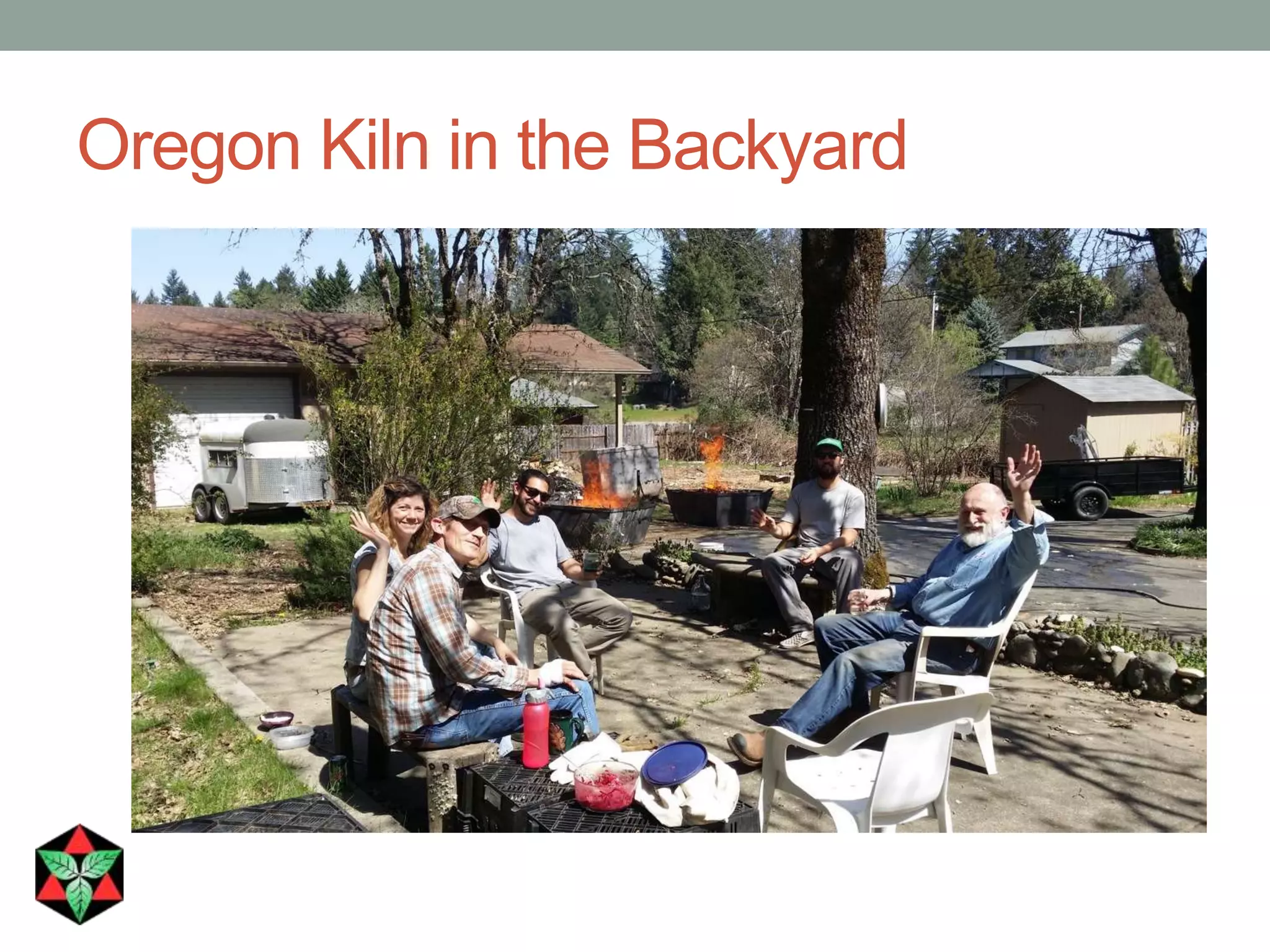

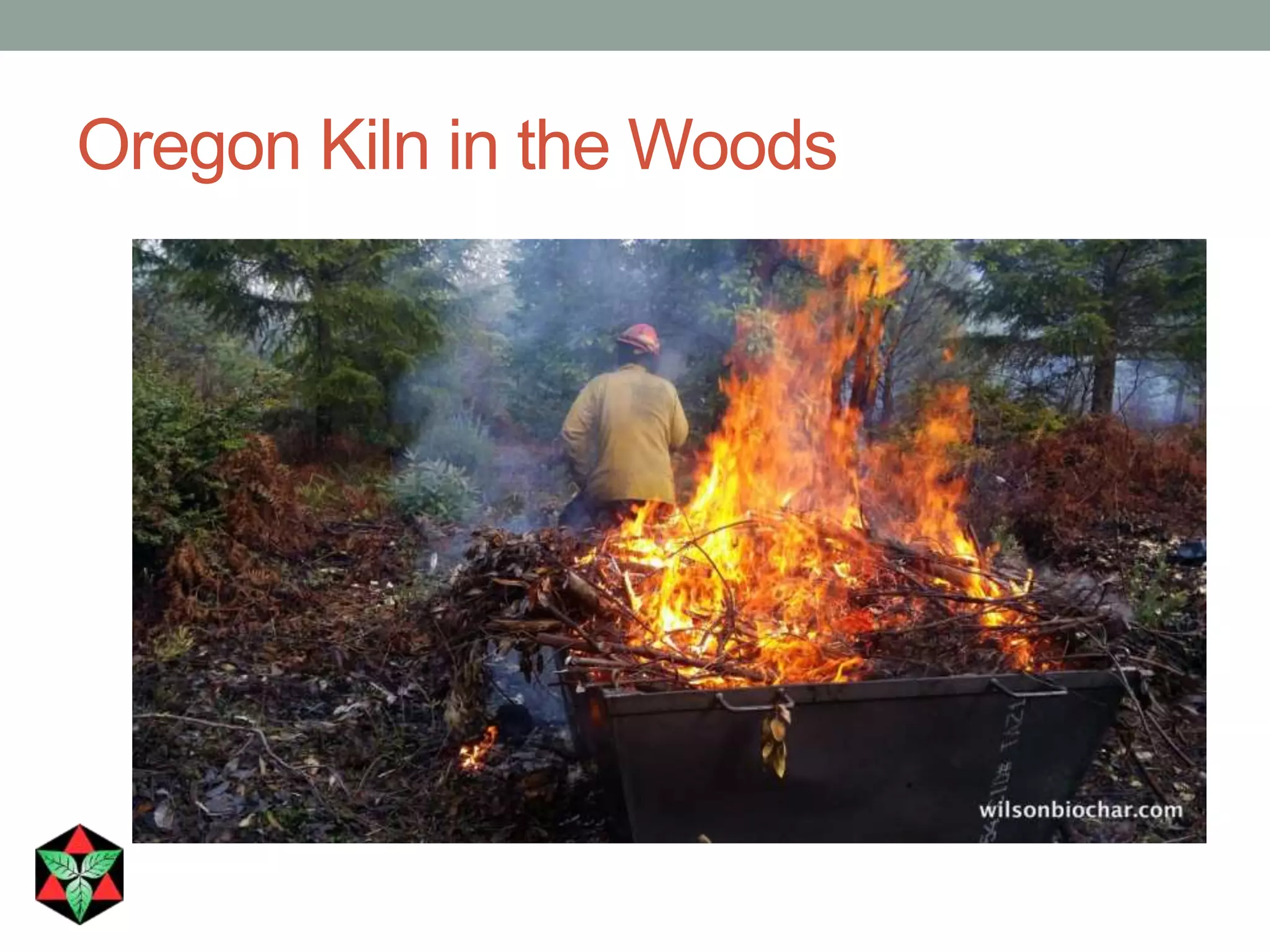

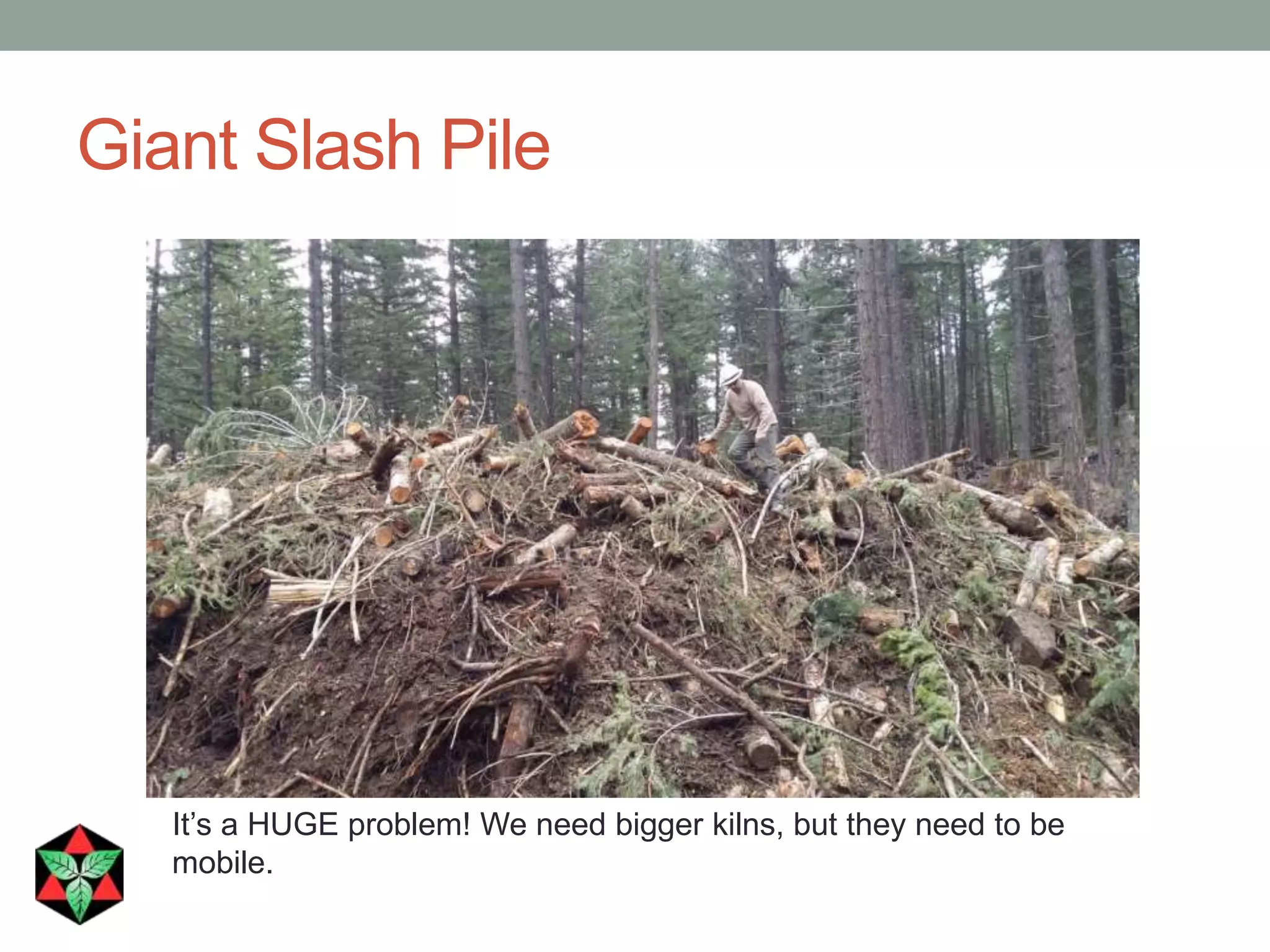

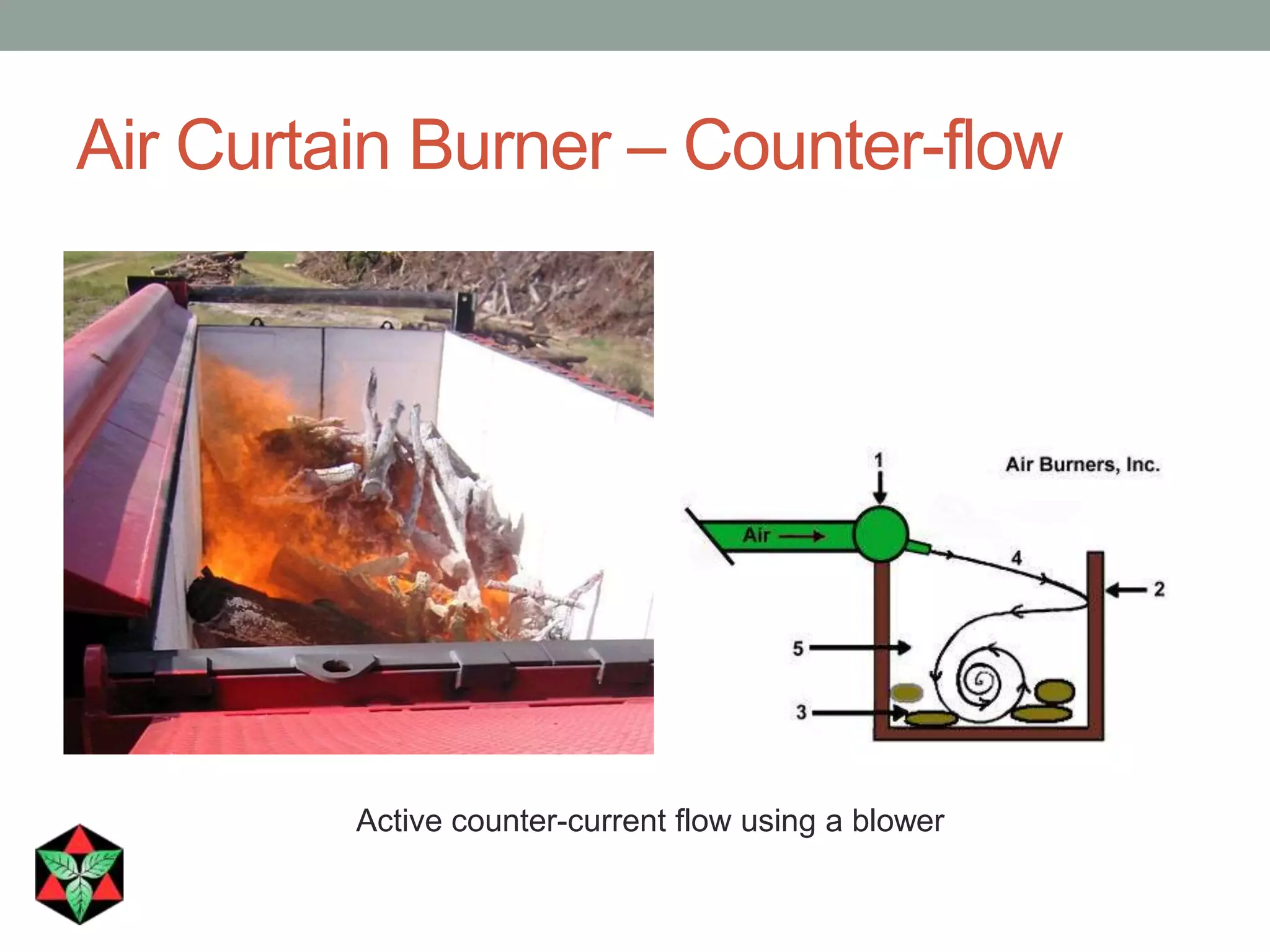

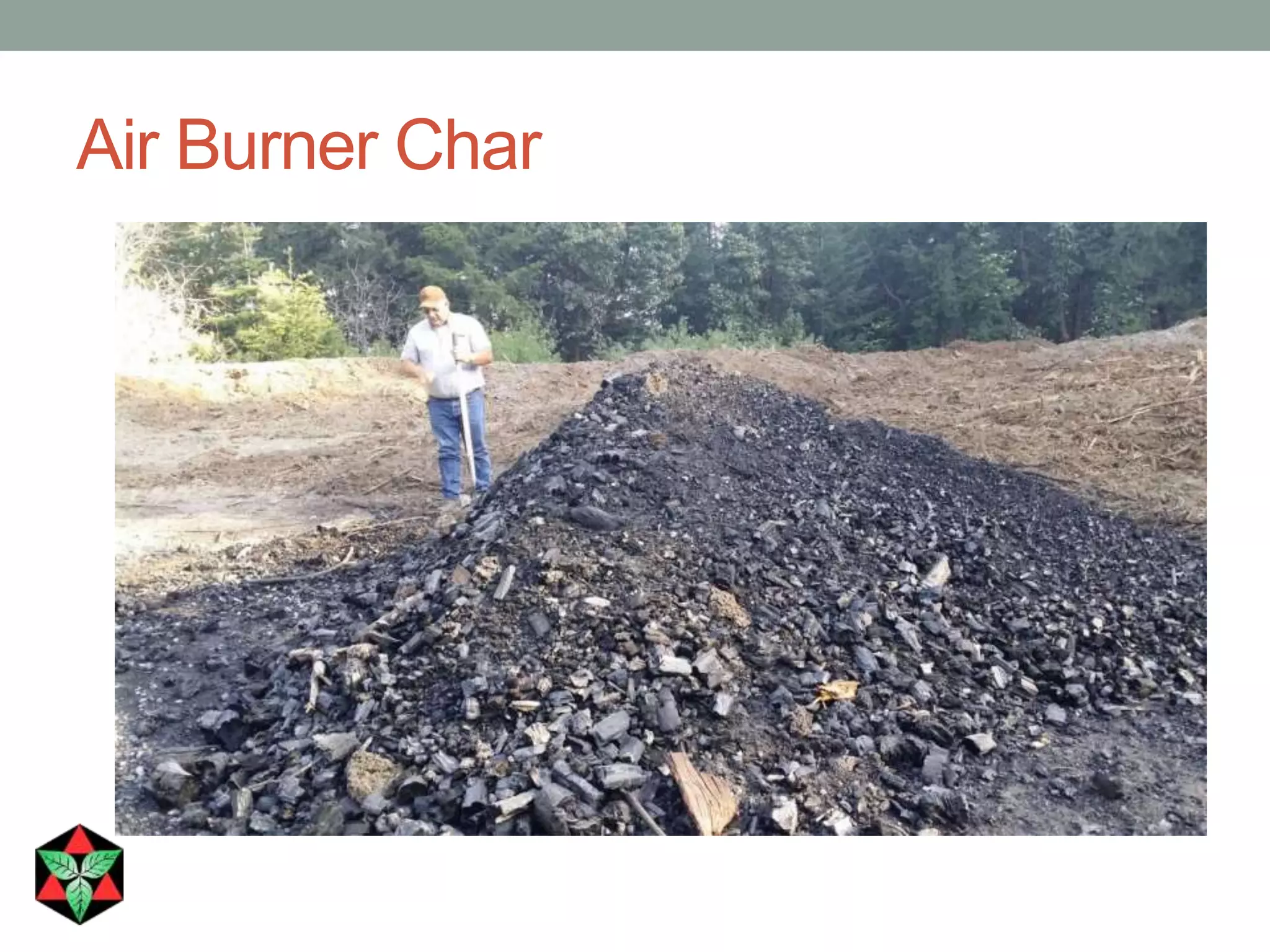

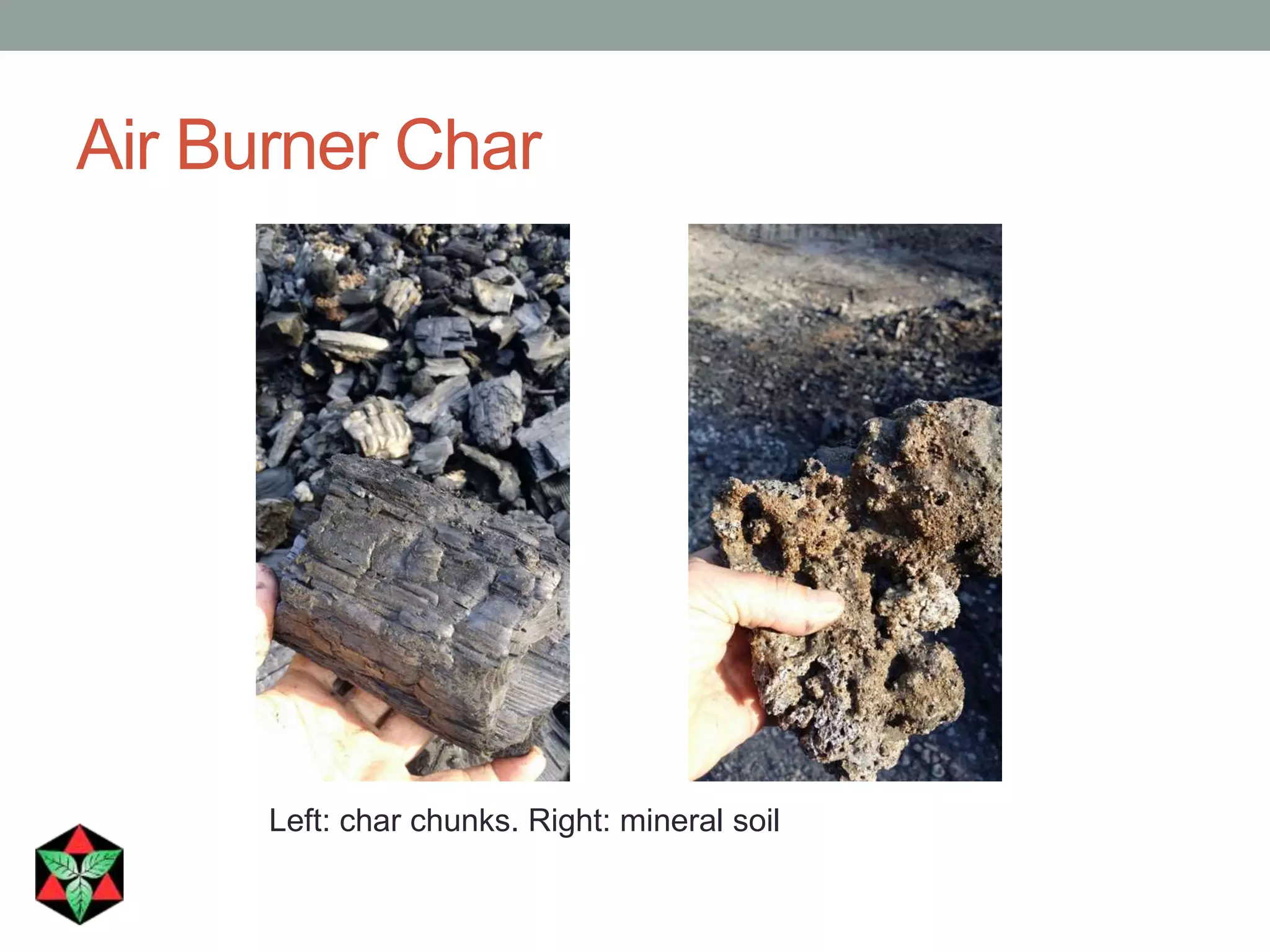

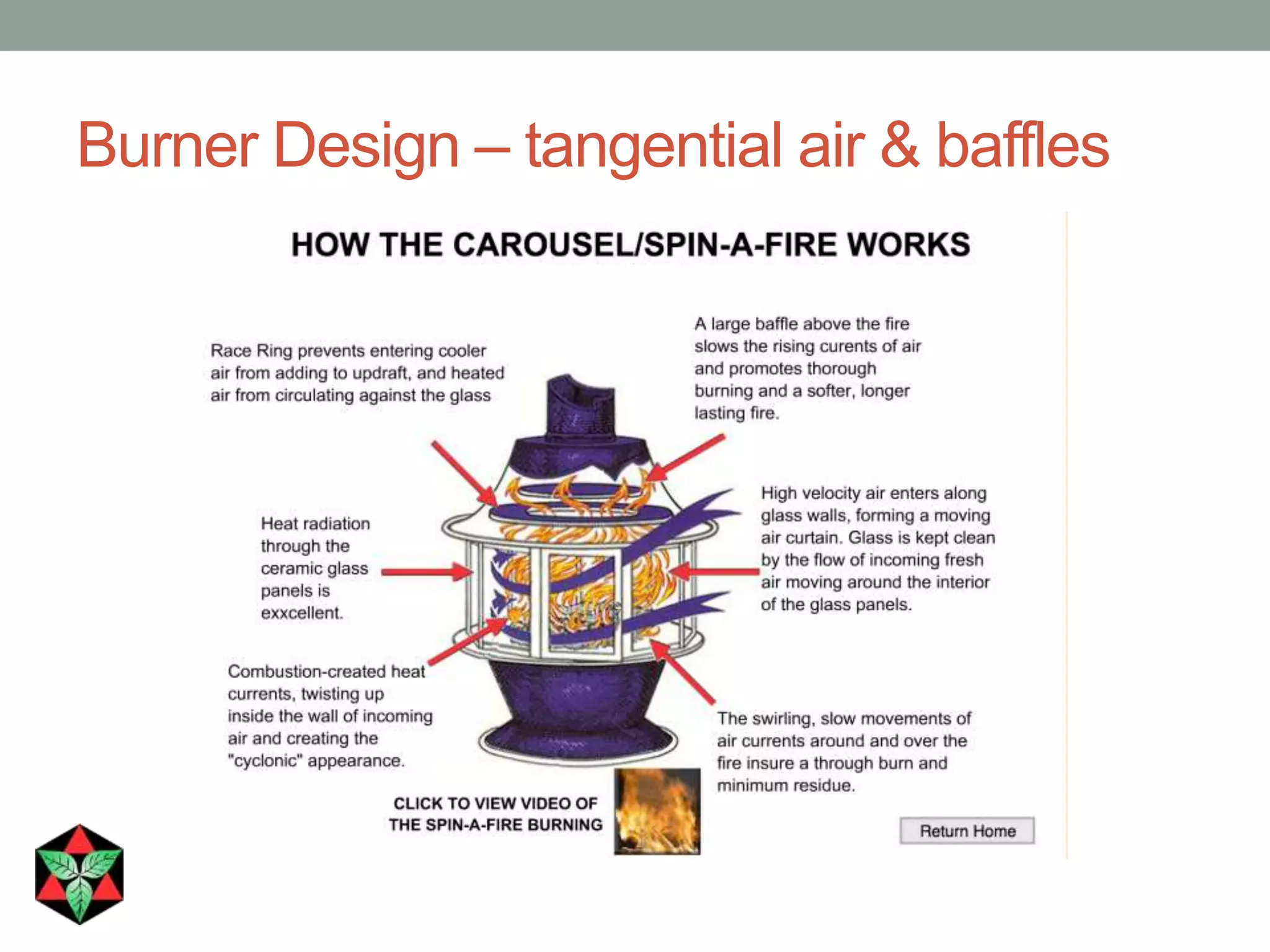

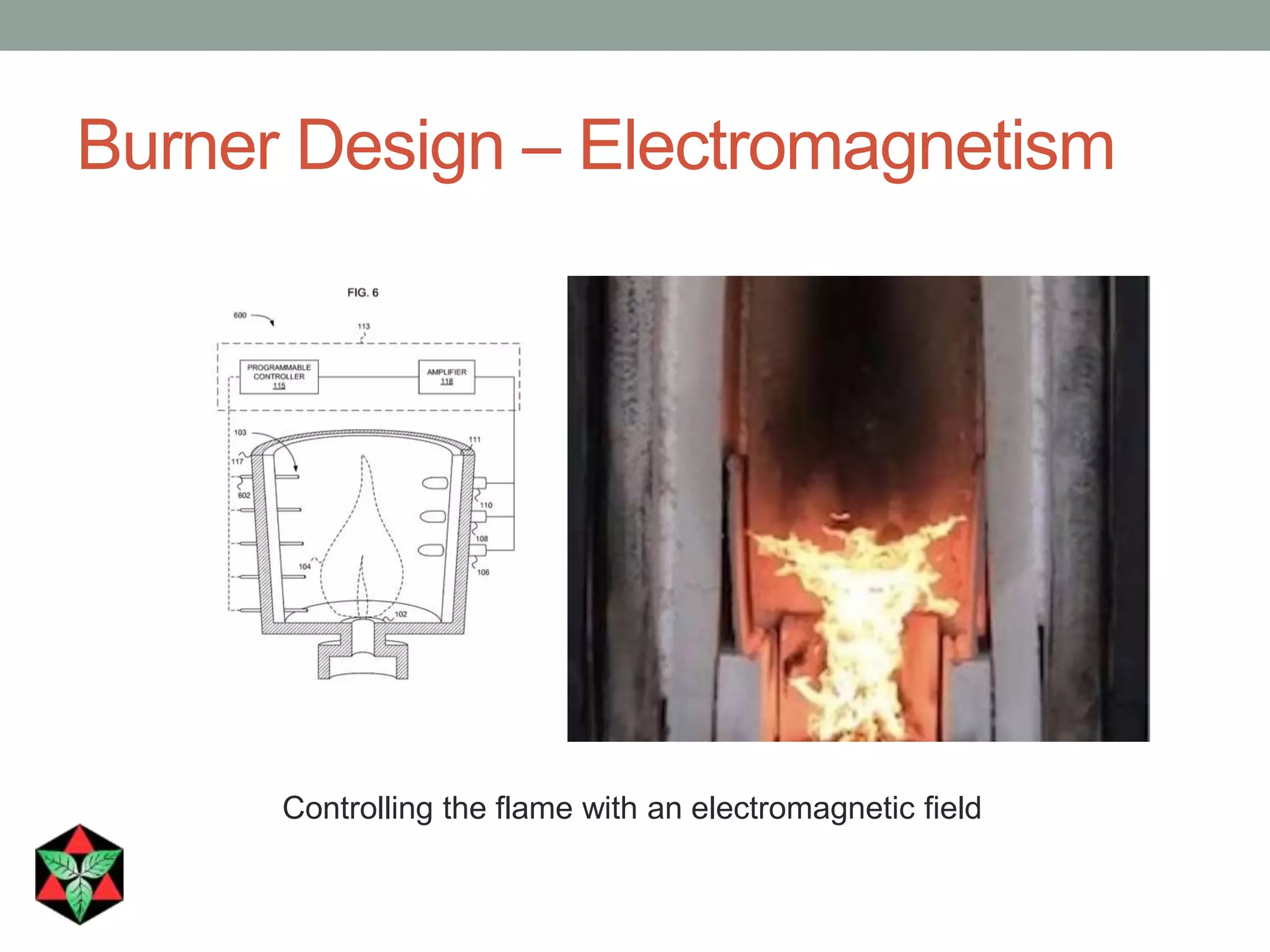

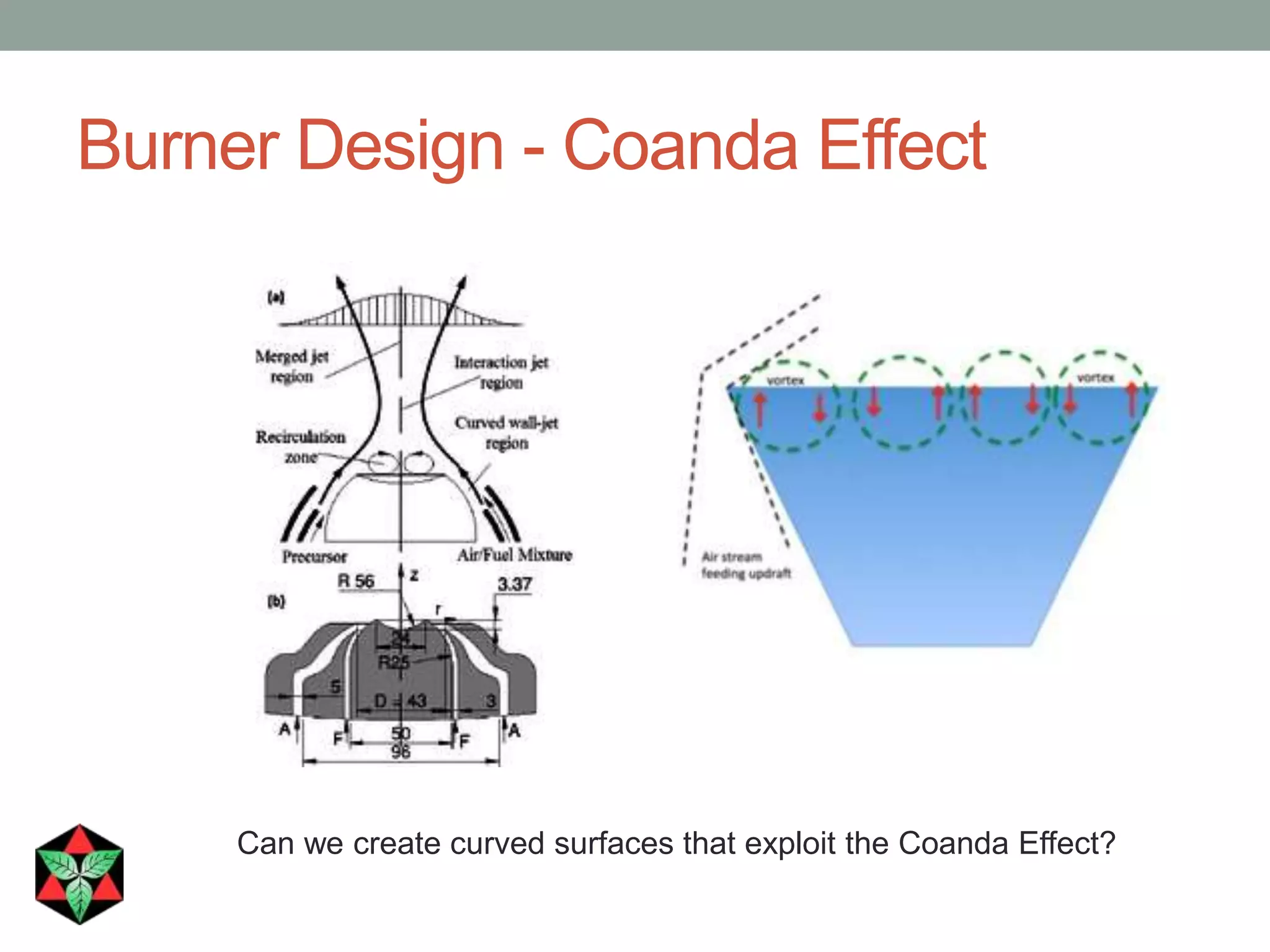

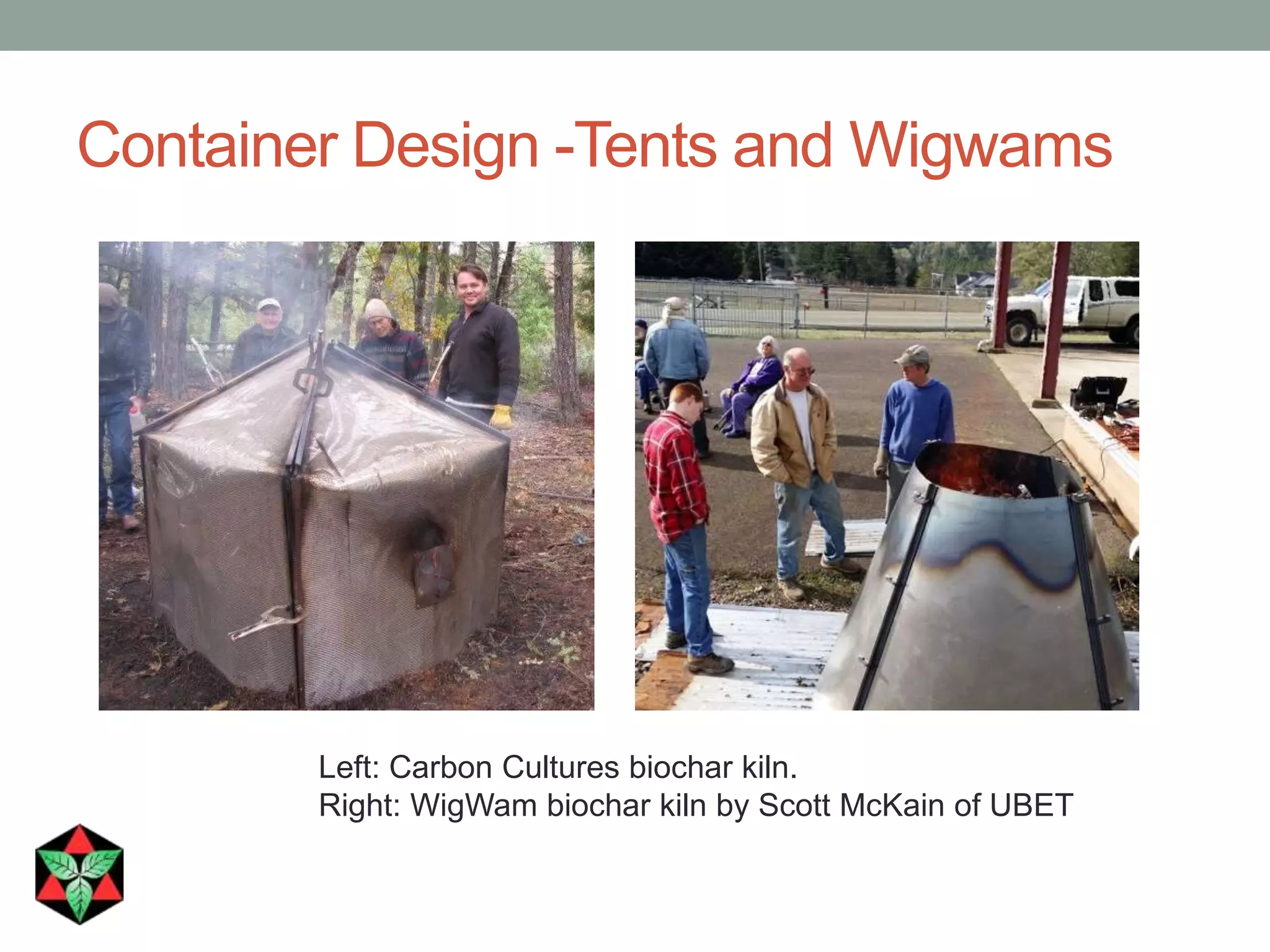

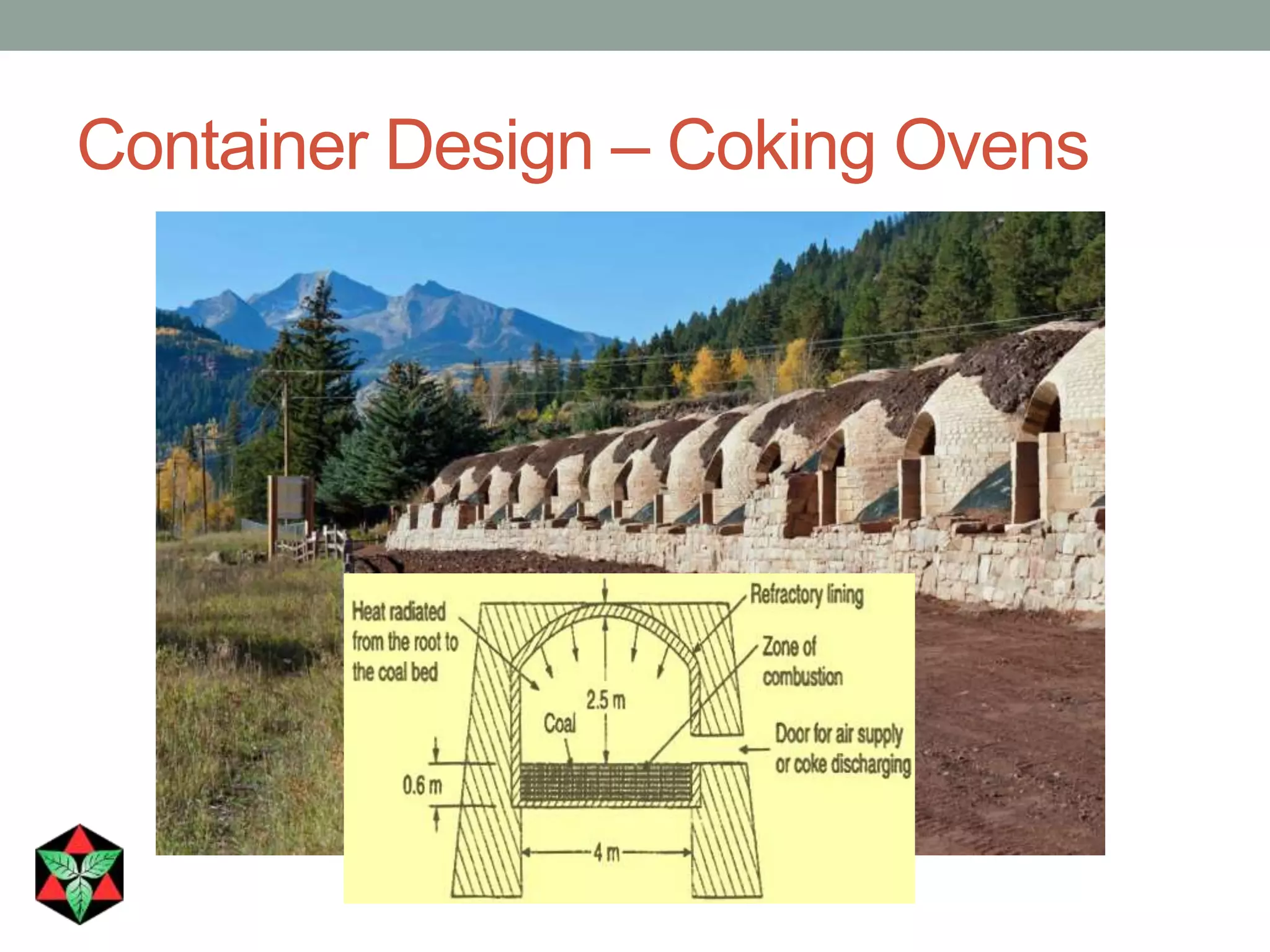

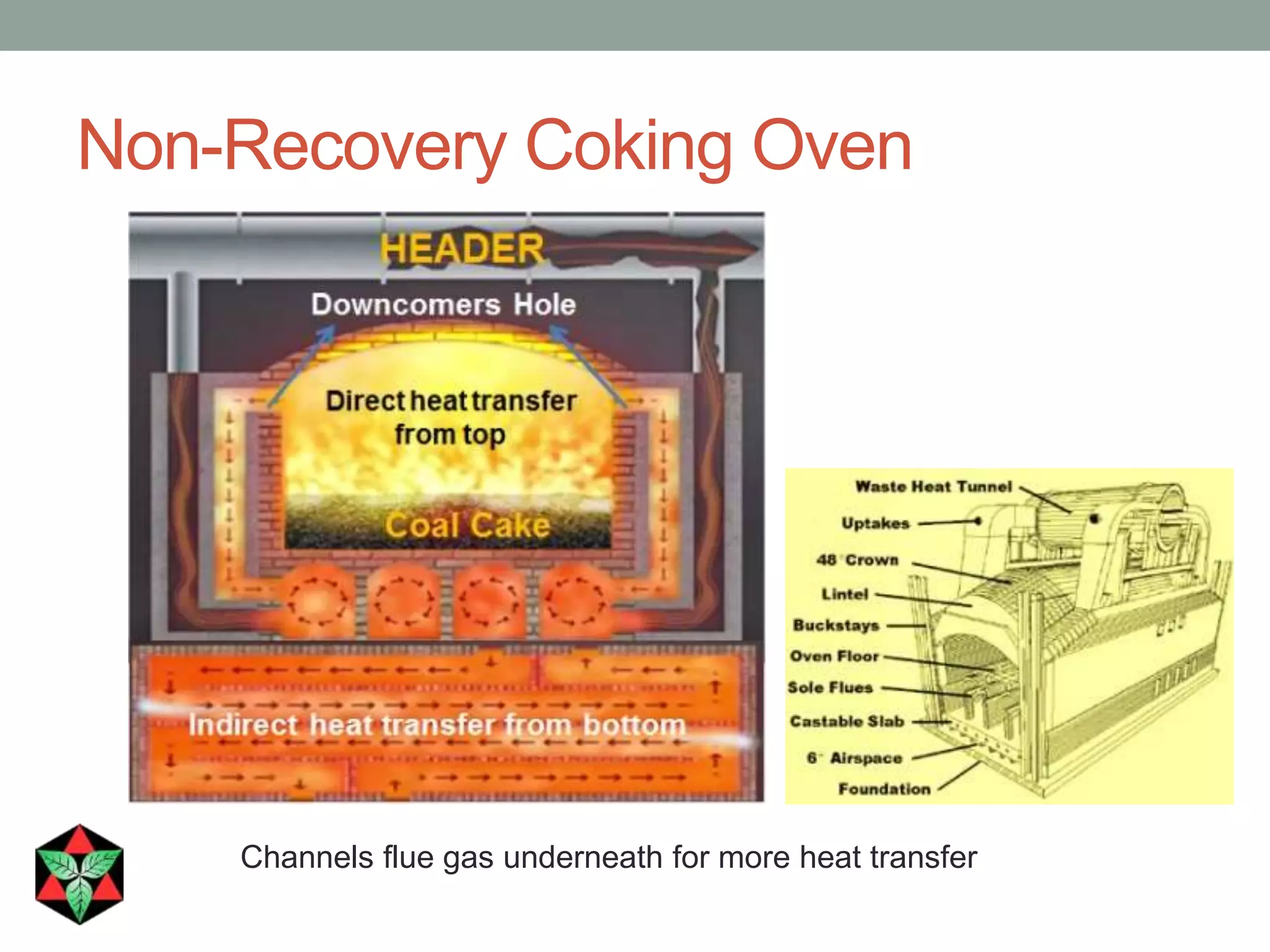

The document discusses flame carbonizers and their design, focusing on various kiln types like the Japanese cone kiln and TLUD gasifiers for biochar production. It explores the principles of heat exchange, air flow patterns, and efficiency comparisons between different combustion methods. The author, Kelpie Wilson, highlights the need for mobile, efficient kilns capable of producing biochar sustainably.