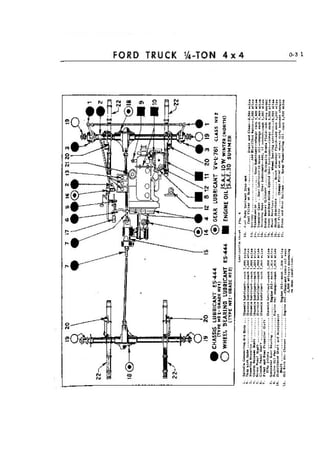

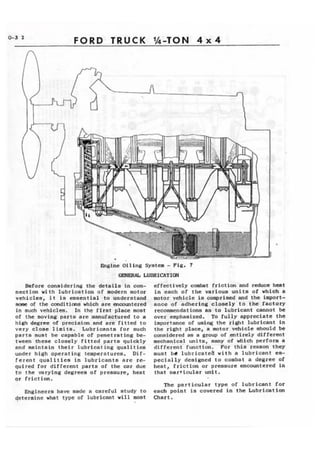

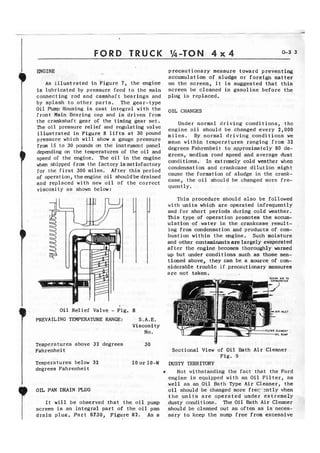

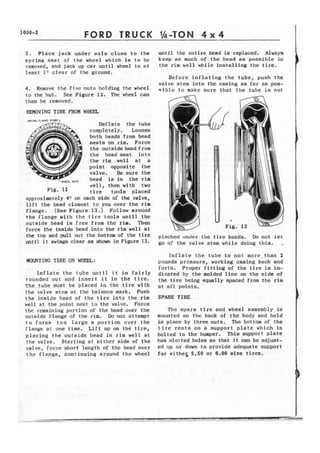

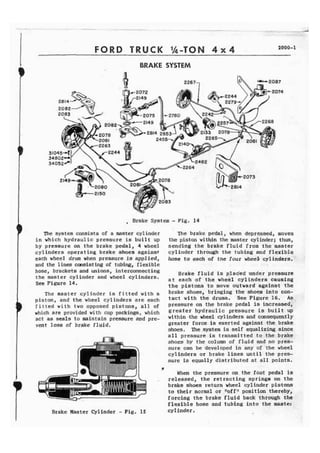

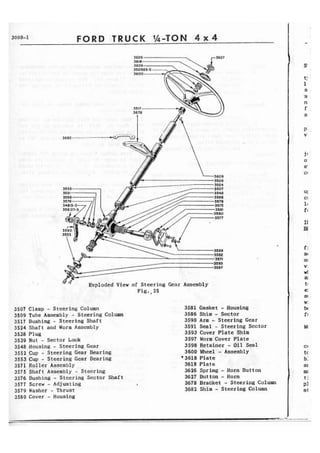

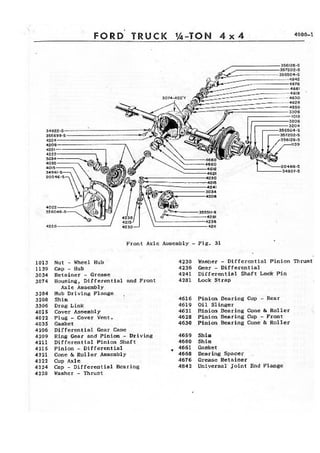

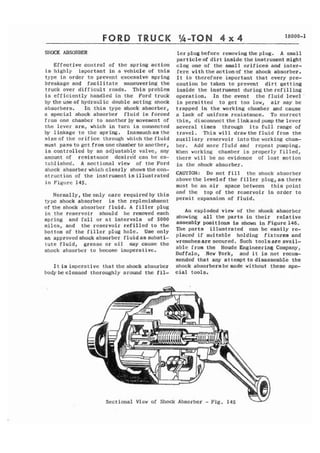

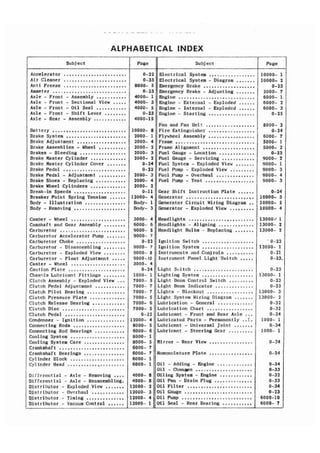

The document provides instructions for lubricating various parts of a Ford truck, including the engine, transmission, axles, steering gear, and shock absorbers. It recommends using specific types and grades of oil for different components, with engine oil changes every 2,000 miles under normal conditions. Other parts like the transmission and transfer case should get oil changes every 5,000 miles. Front axles and universal joints require special hypoid gear oil and grease. Periodic checks and maintenance are advised to ensure proper lubrication.