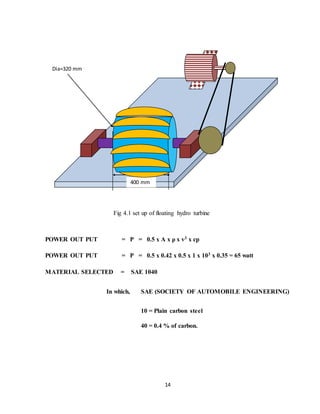

This document provides an overview of a student group project to design a small hydroelectric generation system using a floating turbine concept. It discusses that the most difficult part will be synchronizing the turbine speed with the generator speed. It also notes that this project will provide insight into challenges of reliable energy sources. The document then provides background information on how hydropower works and the typical components of hydropower plants.

![3

Chapter 2

HISTORY OF HYDROELECTRIC GENERATORS

2.1 HISTORICAL BACKGROUND:

Power plays a great role wherever main lives and works in industry, agriculture etc, Power

provides our homes with light and heat. The living standard and prosperity of a nation very

directly with increases in use of power. As technology is advancing the consumption of power is

steadily rising.

This necessary that in addition to petroleum etc. other sources of energy should be Searched out

and new add more efficient ways of producing energy should be devised. Nuclear energy has

enlarged the world’s power resources. The energy released by Burning one kilogram of uranium

is equivalent to the energy obtained by burning 4500 Tonnes of high grade coal. In our country

the total generating capacity at the beginning Of First Five Year Plan was 2.3 million Kw . This

capacity was raised to 3.4 million KW by the end of first plan, 5.6 million kW by the end of

second plan and 10.5 million Kw by the end of third plan. In 1969-70 it was 15.5 million Kw

during the fourth Abd fufth plan the generating capacity targets are of the order of 20 million kW

Kw respectively.

In our country the natural resources are found in coal, lignite, oil, hydro sources and nuclear

fuels. These resources should be exploited in the most efficient form by using Improved

technology so that power at cheaper rates becomes available, which will help To accelerate the

growth of industry. It is found that these resources are located in an uneven form in the country

which requires interlinking the grid system of adjoining States so that power generation by

hydro, thermal and nuclear plants could be well Co-ordinate. This will ensure a constant supply

of power to all consumers throughout the country. In northern part of the country hydro power is

the main source available] whereas in Madhya Pradesh and Eastern Maharashtra coal and hydro

sources are Available. But in Gujarat and Western Maharashtra practically no resources are

available. Therefore, power should be denerated either by nuclear power plants or byh thermal

Power plants depending upon the relative economics. Mysore and Kerala both hydro And coal

resources and Tamil Nadu depends upon the thermal power at Neyveli. West Bengal, Southern](https://image.slidesharecdn.com/2finalflotinghydroturbine-190524151654/85/Final-floating-hydro-turbine-3-320.jpg)