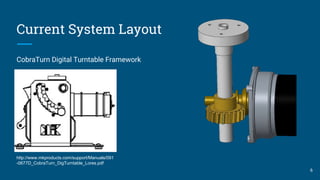

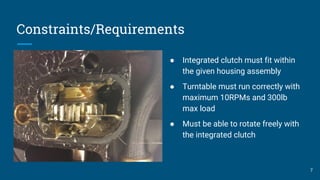

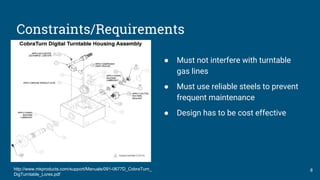

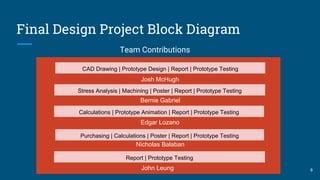

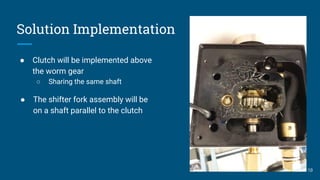

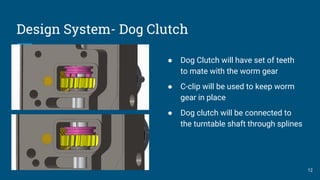

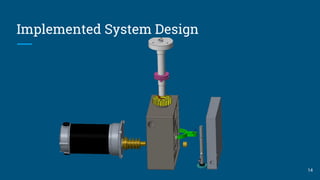

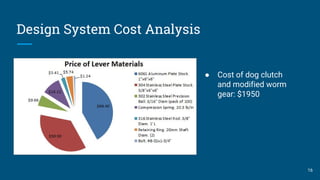

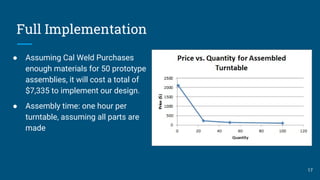

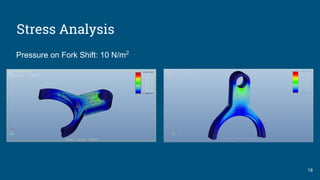

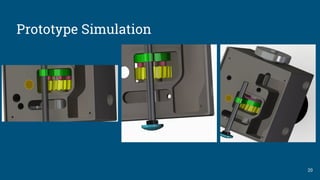

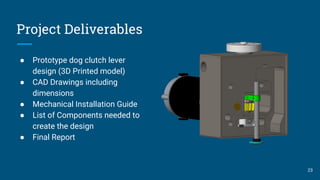

The document provides details of Integrated Designs' final design review for their project to add an integrated clutch system to Cal Weld's position welder turntable. The proposed solution uses a dog clutch engaged by a shifter fork and lever to allow the turntable to freely rotate without electromagnetic interference from the motor. The design was prototyped using 3D printing and stainless steel components. Stress analysis and cost estimates were provided to demonstrate the viability of the integrated clutch system solution.