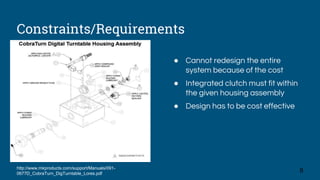

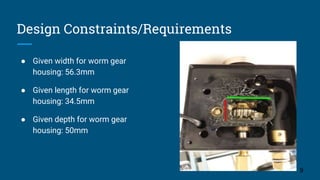

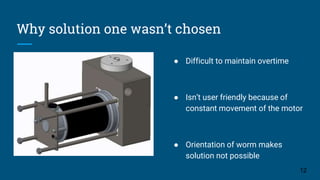

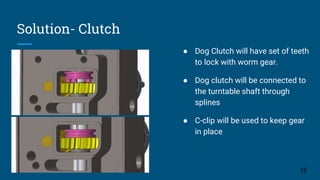

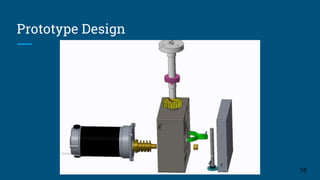

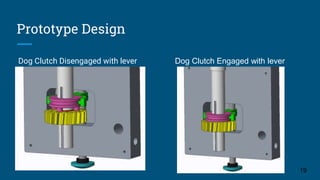

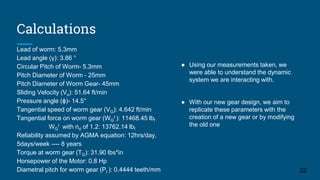

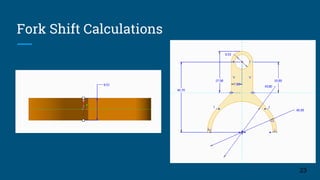

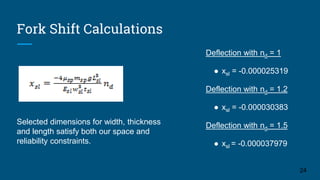

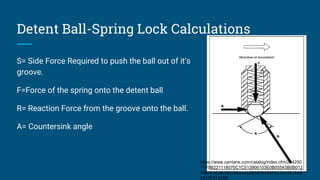

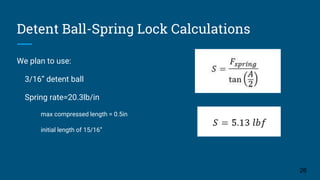

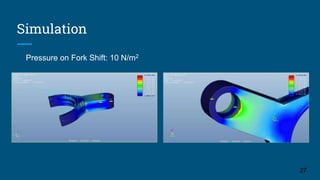

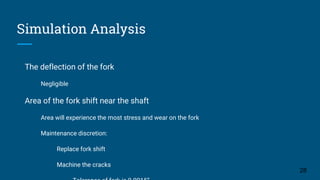

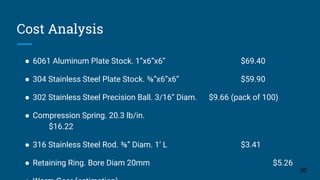

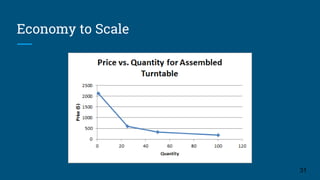

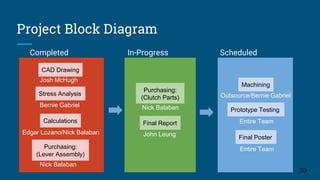

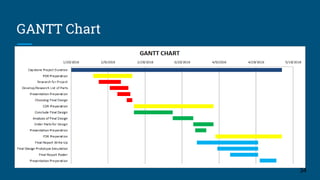

The team presented their critical design review for a position welder turntable clutch system. The team aims to create a functional clutch mechanism that engages and disengages the turntable within the given housing constraints. Their proposed solution uses a dog clutch engaged by a lever-actuated fork shifter assembly. Calculations were presented to analyze the gear dynamics, fork shift deflection, and detent ball-spring lock. A prototype is being machined and will undergo testing to validate the design meets the project requirements within budget and on schedule.