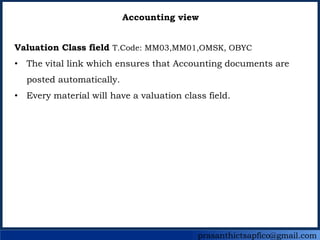

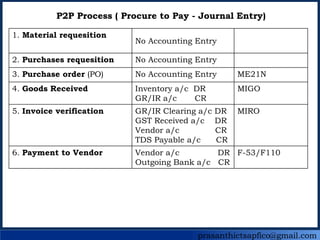

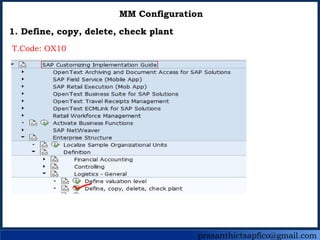

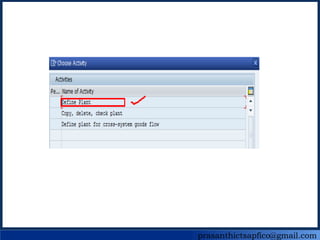

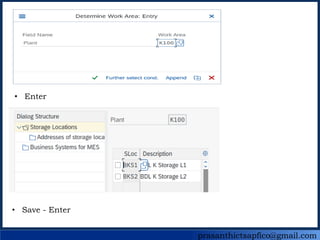

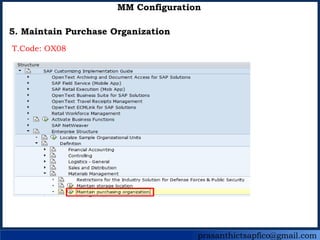

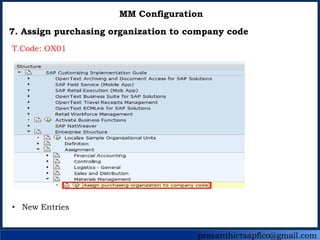

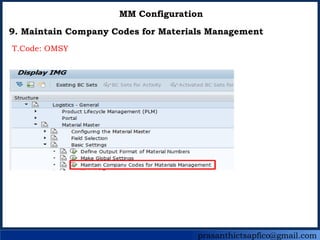

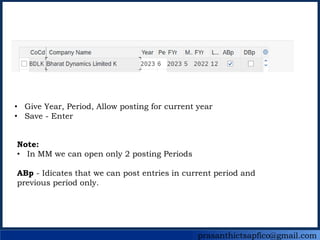

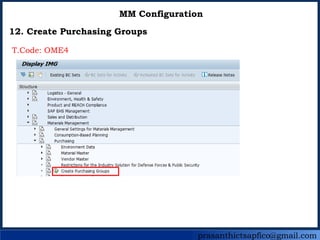

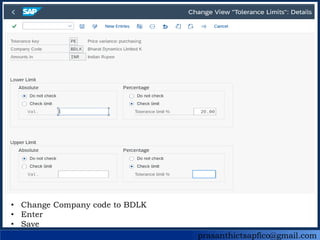

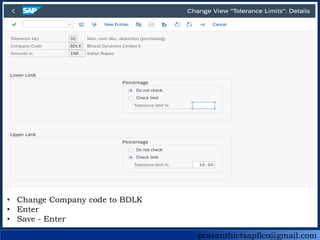

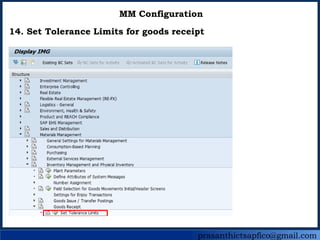

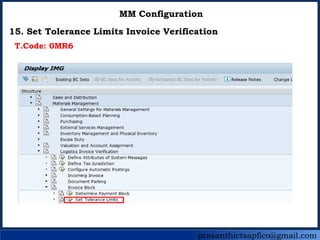

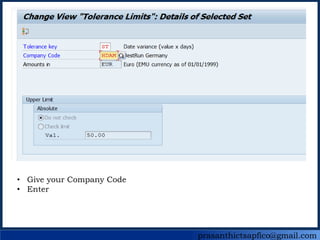

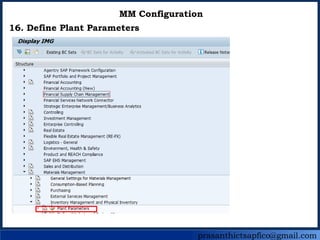

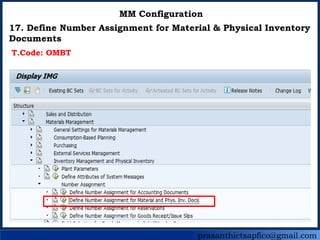

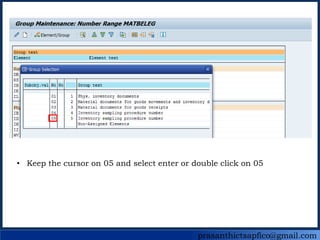

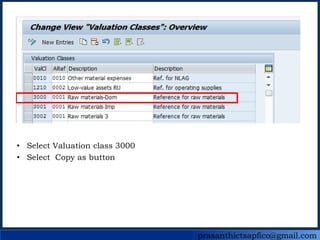

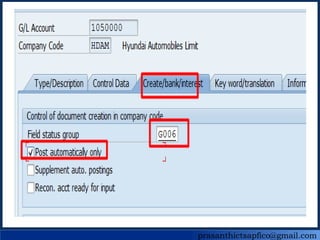

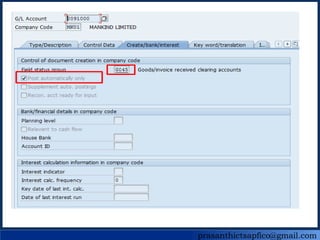

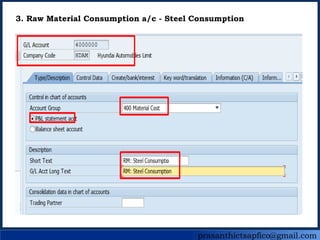

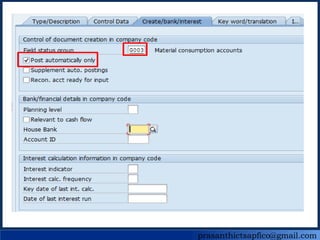

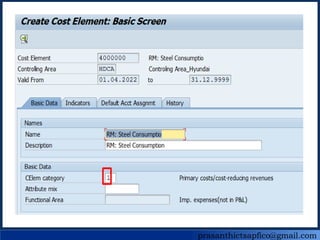

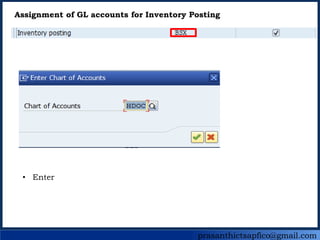

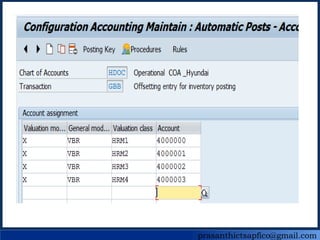

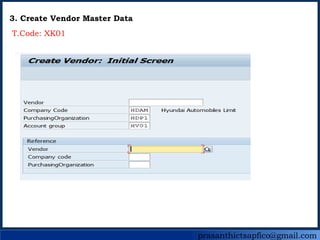

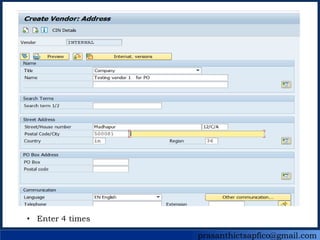

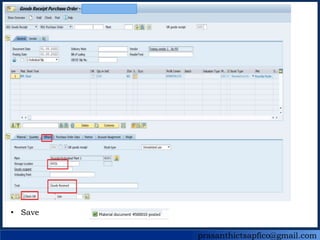

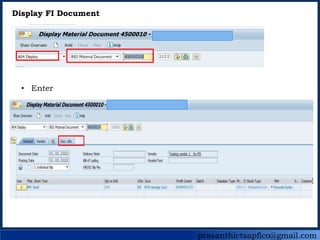

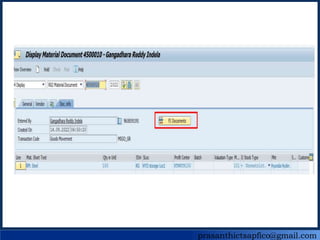

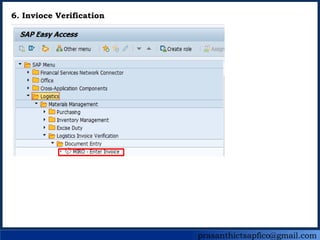

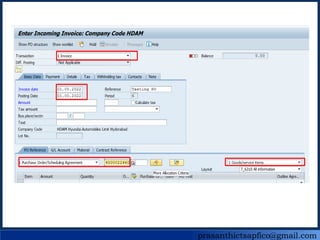

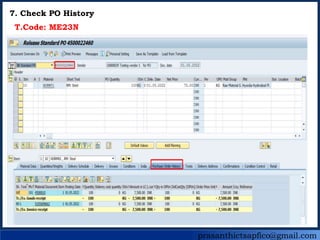

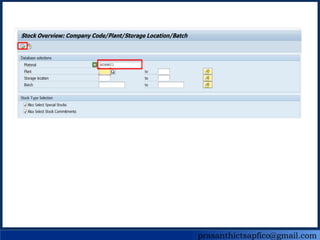

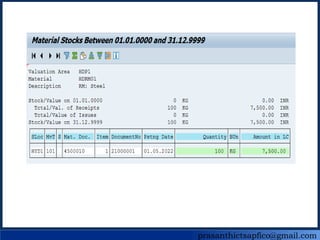

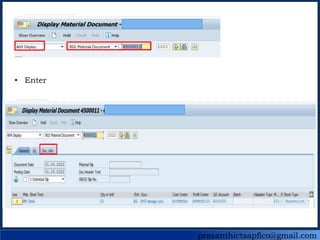

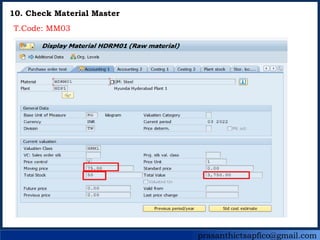

This document discusses the configuration steps required for materials management (MM) and financial accounting (FI) in SAP. It explains the key MM concepts of company code, plant, storage location, material master, valuation class, and movement type. It also describes the procurement to pay (P2P) process and provides examples of configuration settings for number assignment, tolerance limits, and account assignments. Basic testing steps are outlined including creating a material, vendor, purchase order, and goods receipt.