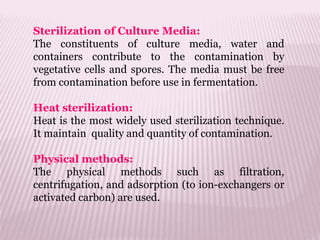

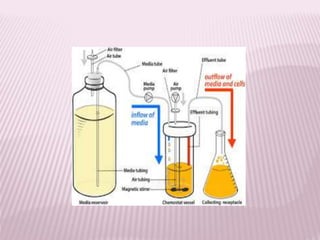

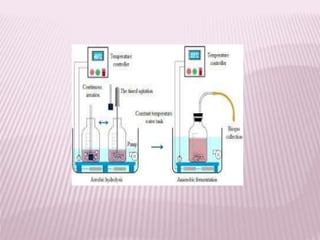

The document elaborates on various fermentation processes, including batch, continuous, and fed-batch fermentation, highlighting their operational characteristics, advantages, and disadvantages. It discusses sterilization methods essential for preventing contamination during fermentation and outlines applications in food and pharmaceutical industries. Additionally, it contrasts aerobic and anaerobic fermentation, detailing their respective merits and potential drawbacks.