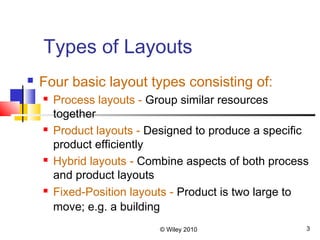

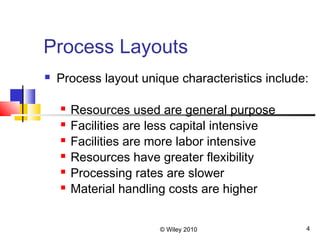

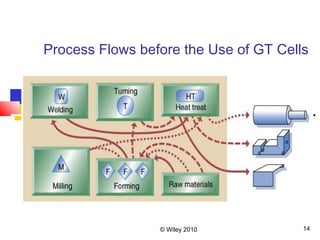

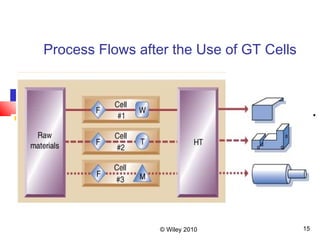

Layout planning involves deciding the best arrangement of resources within a facility to maximize productivity. There are four main types of layouts: process layouts group similar resources, product layouts are designed for specific products, hybrid layouts combine aspects of process and product, and fixed-position layouts cannot move large products. Process layouts have flexible resources but slower speeds, while product layouts have specialized resources and faster speeds. Warehouse and office layouts also require special considerations around resource placement and human factors. Group technology cellular layouts can bring product layout efficiencies to process environments by grouping similar tasks into cells.