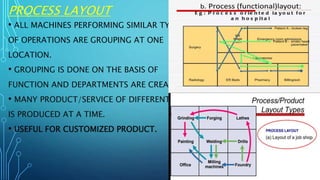

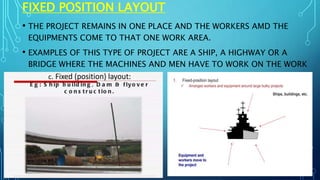

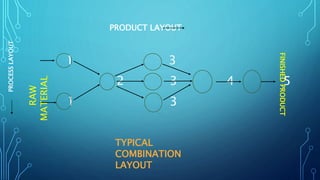

Facility layout refers to the arrangement of manufacturing elements to achieve desired production results, considering factors like space, safety, and convenience. It includes various types like product layout for mass production, process layout for customizable products, fixed position layout for projects, and combination layout integrating features of both. The objectives focus on optimizing space, promoting safety, reducing movements, and enhancing production capacity.