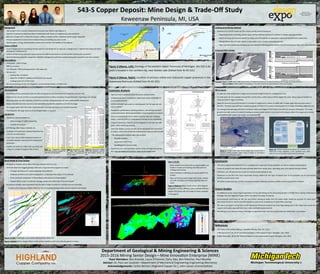

This document summarizes a study evaluating mining methods for the 543-S copper deposit in Michigan's Keweenaw Peninsula. An underground cut-and-fill method was selected based on the deposit's geometry. A block model of the deposit was created from drill data. Economic analysis was conducted to determine optimal pit limits and underground development. The study concluded the deposit has potential for open-pit, underground, or hybrid mining and that cut-and-fill is reasonable given the deposit. Future work includes environmental monitoring and feasibility assessments.