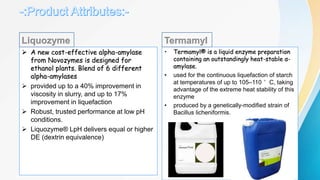

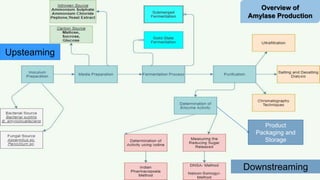

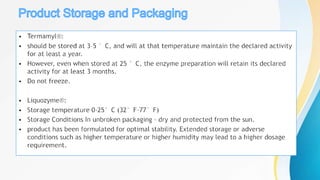

Novozymes produces two alpha-amylase products - Liquozyme and Termamyl. Liquozyme is designed for ethanol plants and provides improvements in viscosity and liquefaction. Termamyl is highly heat-stable and can be used at temperatures up to 105–110 °C. The document discusses the production, purification, and characterization of alpha-amylases from microbial sources including various fermentation and downstream processing methods.