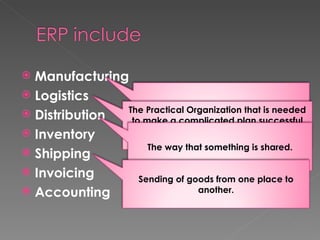

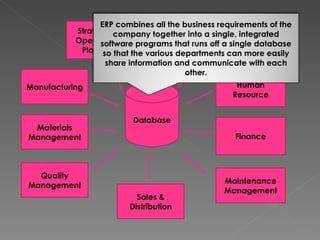

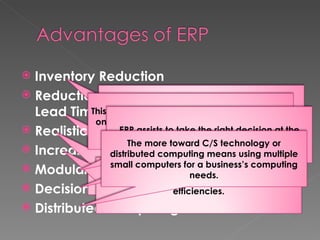

ERP systems integrate and automate key business functions across an organization. They provide a single, integrated software program that runs from a single database, allowing different departments to easily share information. ERP combines functions like manufacturing, logistics, distribution, inventory, shipping, invoicing, accounting, and more. It provides benefits like end-to-end supply chain management, flexible reporting, seamless integration of data, and coordinated inventories and production planning.