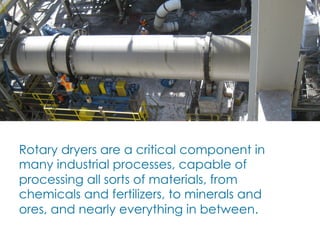

The document discusses the critical importance of properly installing rotary dryers, which are essential in various industrial processes. Proper installation helps prolong the equipment's life, prevent downtime, and avoid costly damage. Key to a successful installation is the presence of a knowledgeable service technician and effective planning between the equipment purchaser, manufacturer, and installation contractor.