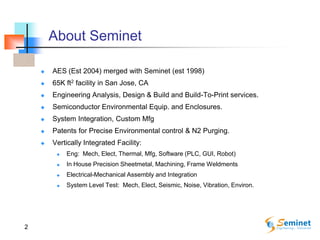

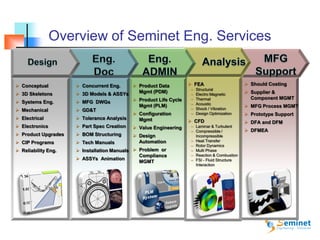

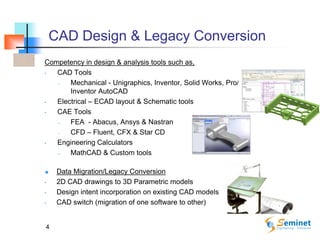

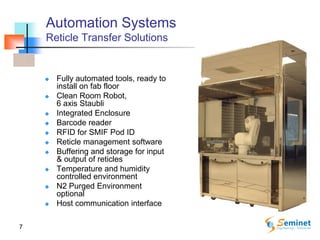

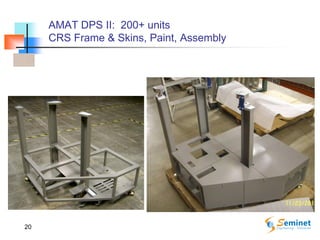

Seminet provides engineering design and manufacturing services including vacuum chamber design and build, precision air handling systems, enclosures, and electro-mechanical assembly and integration. Located in San Jose, CA, Seminet has 65,000 square feet of facilities for engineering analysis, custom manufacturing, and vertically integrated system integration and testing. Seminet specializes in semiconductor and environmental equipment and has patents for precise environmental control and nitrogen purging systems.