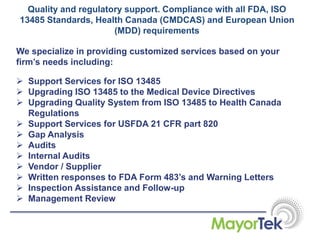

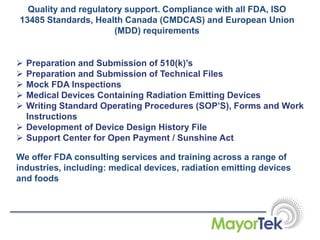

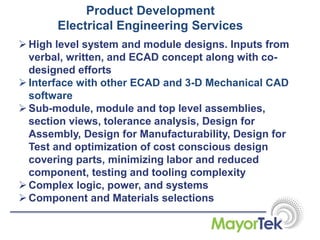

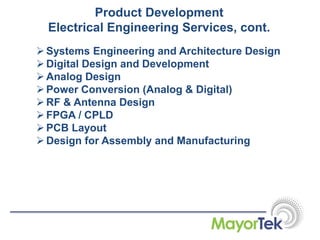

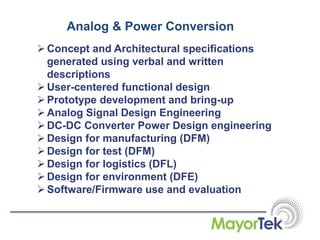

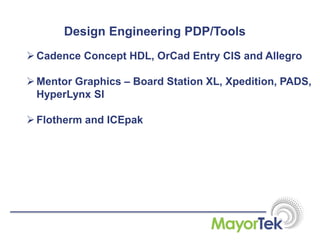

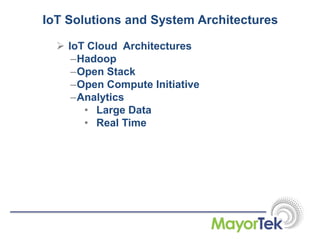

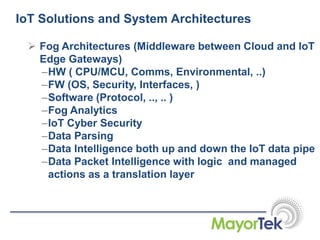

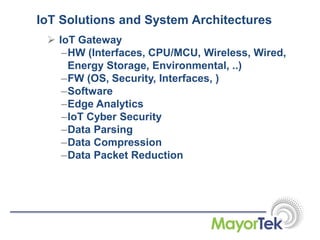

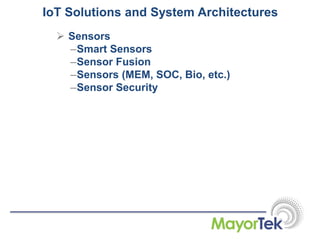

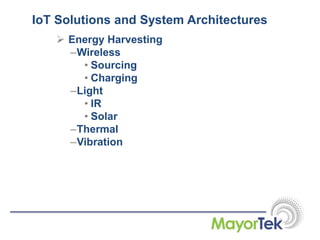

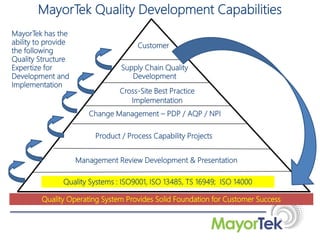

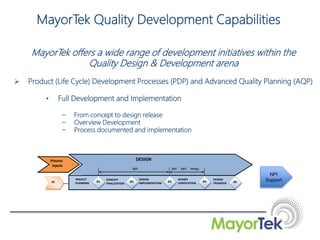

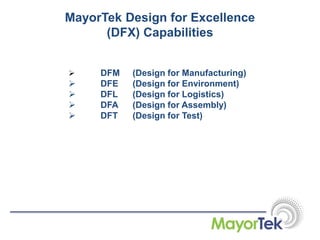

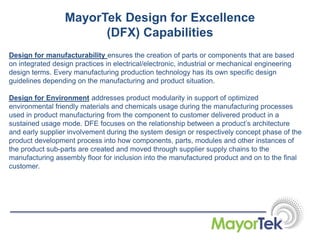

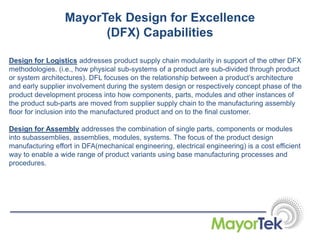

The document provides an overview of technical services offered by MayorTek including product development, engineering design, quality management, project management, and various specialized services. Key services described include mechanical, electrical, and software engineering; industrial design; systems architecture; testing; regulatory compliance; value analysis; and approaches to optimize design such as design for manufacturing and quality.