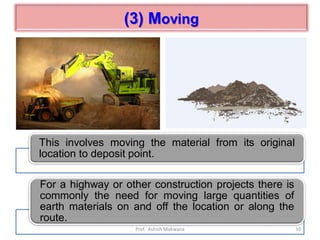

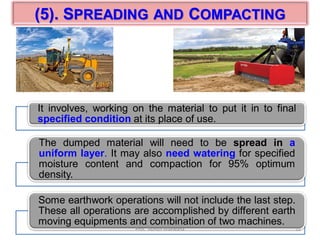

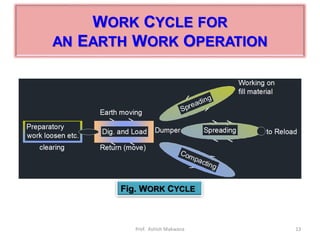

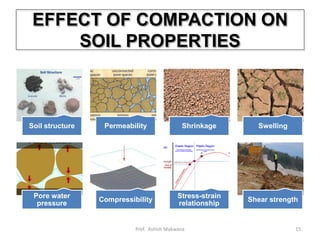

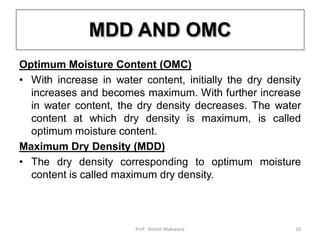

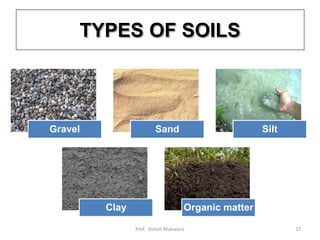

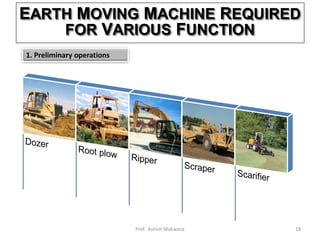

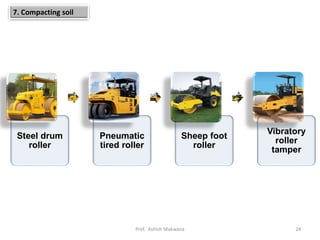

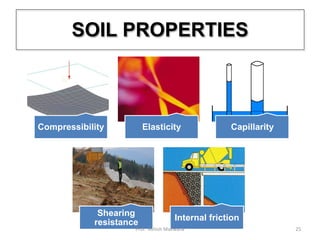

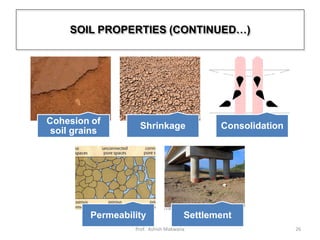

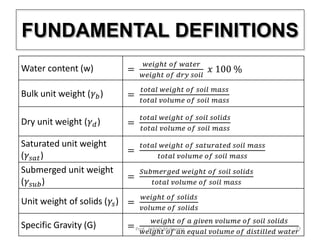

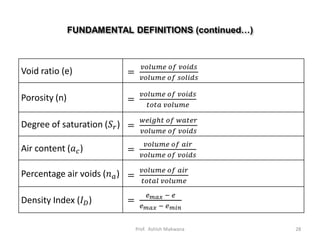

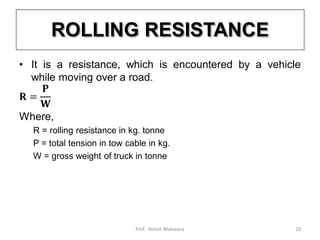

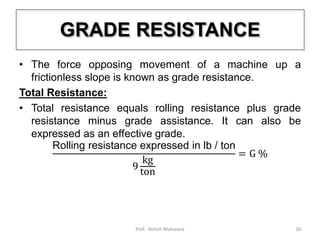

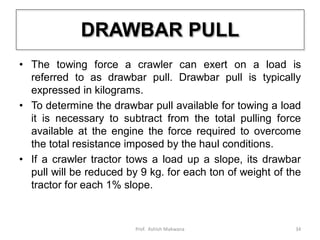

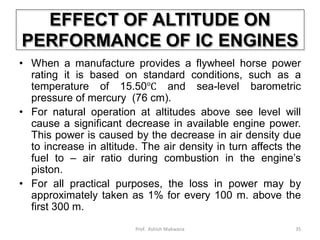

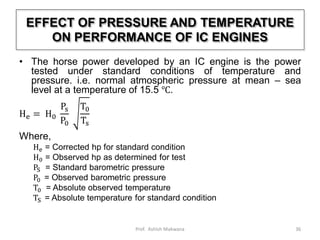

This document, prepared by Prof. Ashish Makwana from the Civil Engineering Department, outlines essential processes and considerations involved in heavy construction projects, particularly focusing on earthmoving operations and soil properties. It discusses various steps such as clearing, digging, moving, dumping, spreading, and compacting, along with terms like compaction, optimum moisture content, and different types of soil. Other critical technical factors related to machine performance and resistance during earthworks, such as rolling resistance, grade resistance, and the effects of altitude on engine performance, are also covered.