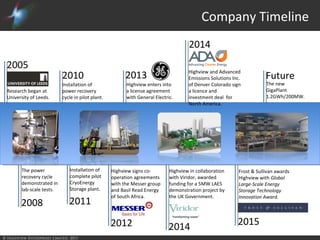

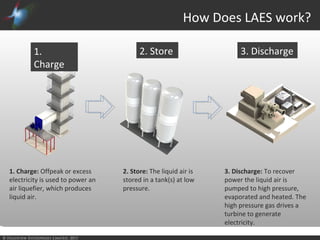

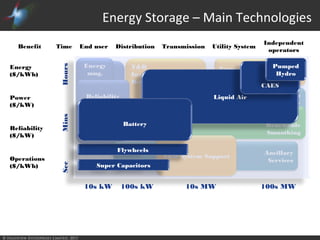

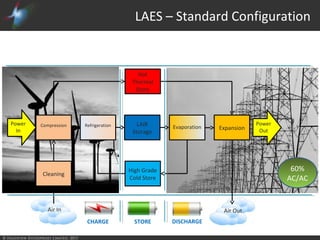

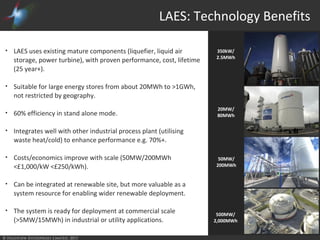

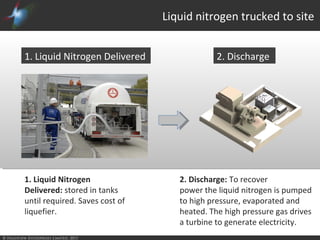

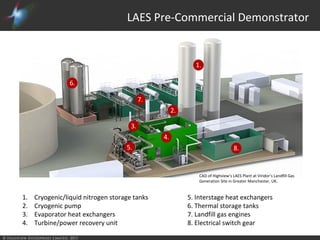

Highview Enterprises is developing a Liquid Air Energy Storage (LAES) technology aimed at providing efficient energy storage solutions. The LAES system can operate at a scale from 20 MWh to over 1 GWh, with a demonstrated efficiency of 60% and potential integration with renewable energy sources. A pre-commercial demonstrator funded by UK government aims to showcase economic performance and reliability at a site near Manchester.