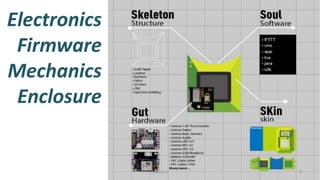

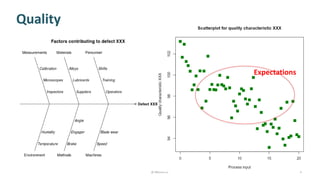

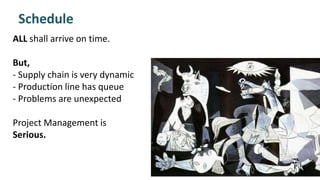

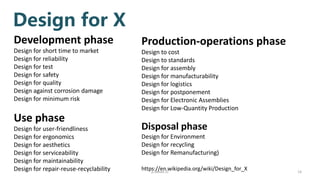

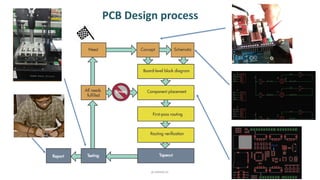

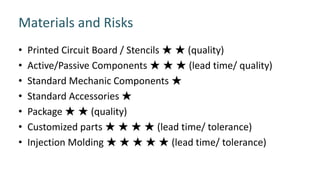

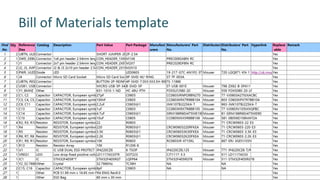

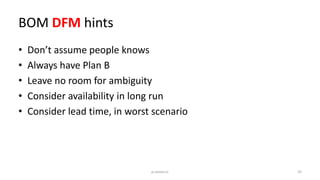

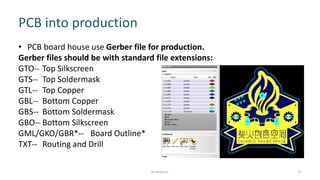

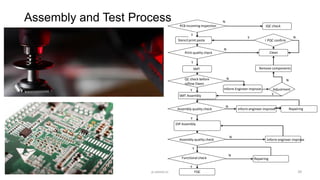

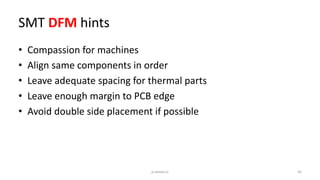

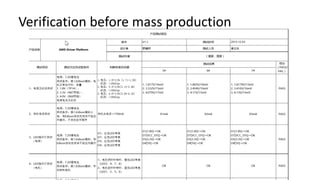

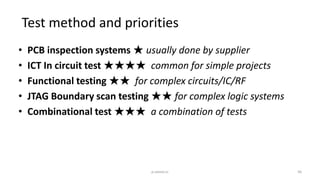

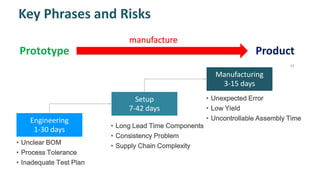

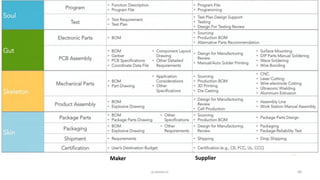

The document outlines the electronic manufacturing process, emphasizing design, materials preparation, assembly, testing, and packaging. It highlights the importance of project management, quality control, and the need for effective workflows across various phases of production. Additionally, it discusses strategies for managing costs, lead times, and potential manufacturing challenges.