The document outlines the design and simulation of an exhaust gas recirculation (EGR) cooler aimed at reducing nitrogen oxide (NOx) emissions in automotive applications. It details the design process, input parameters, and computational methods used to achieve effective cooling of recirculated exhaust gases as mandated by stringent automotive emission norms in India. The study emphasizes the necessity for a high-performance EGR cooler and discusses various techniques for NOx reduction across different stages of combustion.

![Automotive Emissions and Norms

• Bharat Stage emission norms are regulations put by Government of India

to control the air pollutants emitted by internal combustion engines

and motor vehicles [1] .

• These are implemented by Central Pollution Control Board (CPCB).

• These were first implemented in year 2000 in accordance with European Emission

norms.

• In year 2010 Bharat IV emission norms were implemented.

• As per the notification released by Government of India in February 2016, it has

been decided to skip Bharat V norms and move towards Bharat VI norms.

• Bharat VI norms will be implemented from April 2020.](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-4-2048.jpg)

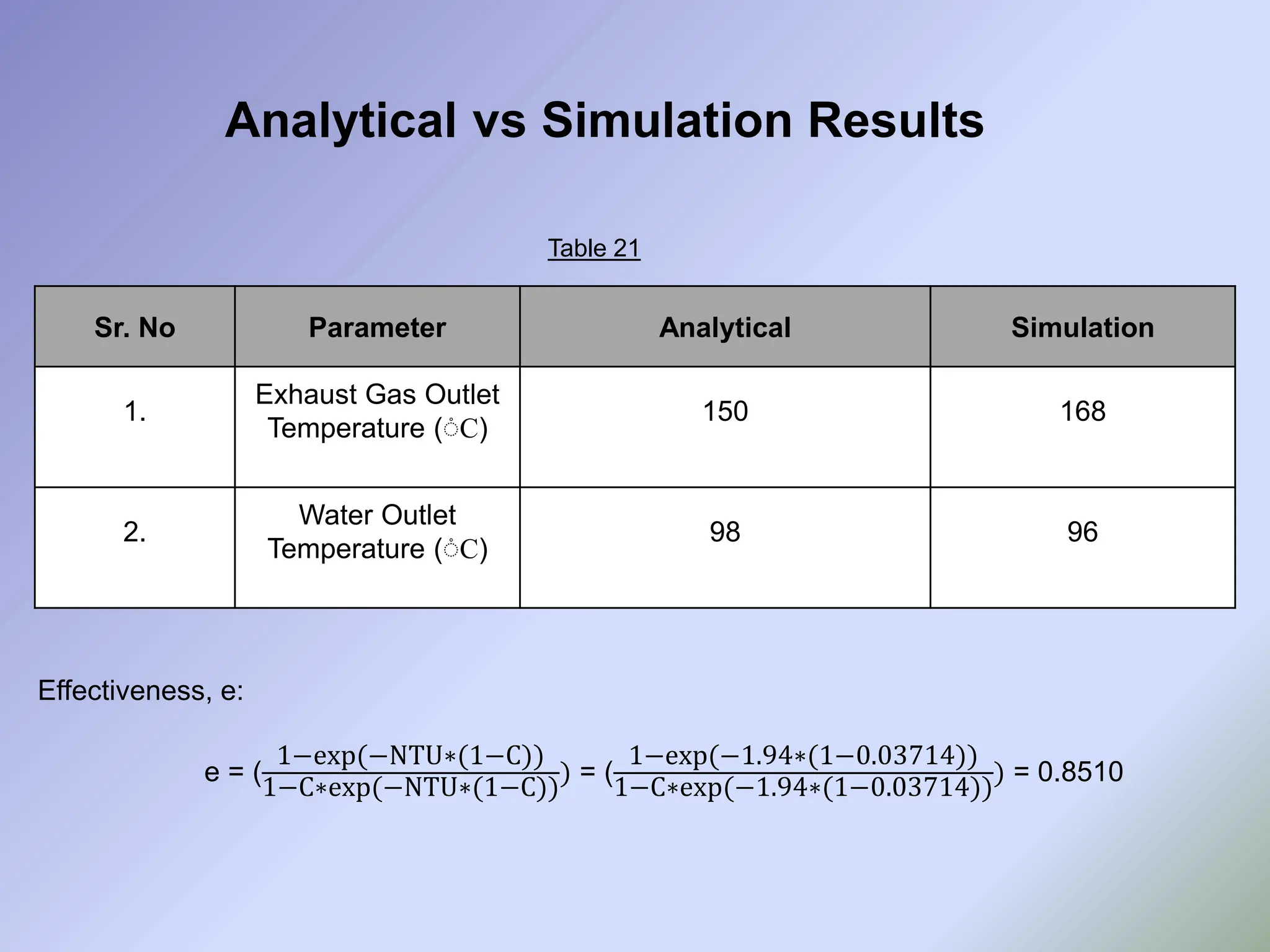

![Comparison Bharat IV, V, VI Norms

Stage CO

(g/km)

HC

(g/km)

HC+Nox

(g/km)

NOx

(g/km)

Gasoline Diesel Gasoline Diesel Gasoline Diesel Gasoline Diesel

BS IV 1 0.5 0.10 - - 0.3 0.08 0.25

BS V 1 0.5 0.10 - - 0.23 0.06 0.18

BS VI 1 0.5 0.10 - - 0.17 0.06 0.08

Table 1 [1]

*For passenger cars](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-5-2048.jpg)

![Techniques Of Reducing NOx

• Techniques of reducing NOx can be categorized along the three different stages

of combustion as enlisted below.[2]

1. Pre-combustion:

Different ways to reduce NOx during pre-combustion are,

- Low Swirl

- Turbo Charger Intercooling

- Fuel Quality

2. During Combustion:

The methods that can be used during combustion to control NOx are,

- Injection

- Combustion chamber

- EGR

3. Post Combustion:

- Selective Non Catalytic Reduction (SNCR)

- Urea Selective Catalytic Reduction (SCR)

- Lean NOx Trap (LNT)](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-6-2048.jpg)

![Exhaust Gas Recirculation

• EGR lowers the combustion temperature which in turn lowers the NOx,

by diluting the mixture in the heat cylinder and absorbing heat from burning fuel.

• The various components of EGR system are shown in figure below.

Figure No. 1 [3]](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-7-2048.jpg)

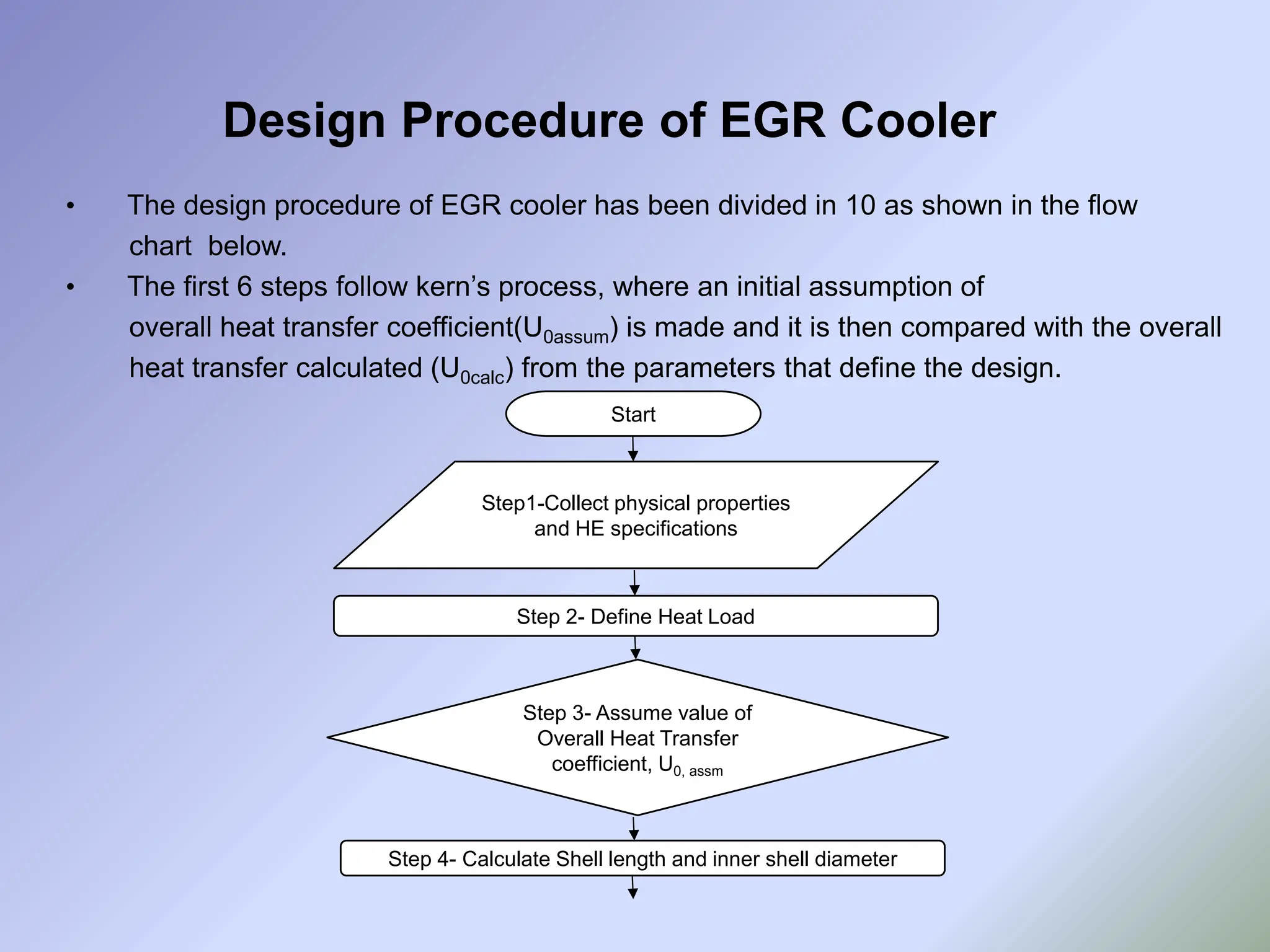

![Step 1- Collect Physical Properties and HE

Specifications

• Physical Properties:

• HE Specifications:

- Exhaust Gas is corrosive so we are assigning it to tube side.

- Using one shell pass and two tube passes

- Shell side fluid is cooling water, which is much cleaner. So considering triangular

pitch to minimize the volume of HE(pitch is the distance between centers of two tube).

Sr. No. Property Exhaust Gas

(HOT air at 800K)

Water

1. Viscosity (Pa-sec) X 10-3 0.0374 0.315

2. Density (kg/m3 ) 0.435 1000

3. Thermal Conductivity (W/m-K) 0.0577 0.6753

4. Specific Heat Capacity (KJ/Kg.K) 1.063 4.187

5. Specific gravity 0.435 * 10-3 1

6. Fouling Factor of exhaust 0.00176 0.00018

Table 4 [4]](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-13-2048.jpg)

![Tube Arrangements

Different types of tube arrangements triangular, rotated triangular, square and rotated

square are shown below (Figure No.3)

A square, or rotated square arrangement, is used for heavily fouling fluids, where it is

necessary to mechanically clean the outside of the tubes, as the shell side fluid is water in

this case, selection of rotated triangular (Refer Fig. No 3) pattern is optimum.

As per recommended by the TEMA( Tubular Exchanger Manufacturer’s Association) for

triangular arrangement of tubes pitch should be 1.25 times the outer diameter of the tube.

Figure No.3 [5]](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-14-2048.jpg)

![Step 3- Assume value of overall heat

transfer coefficient U0, assm

• Typical values of the overall heat-

transfer coefficient for various types of

heat exchanger are given in Figure 4.

• Figure No.4 can be used to estimate the

overall coefficient for tubular exchangers

(shell and tube).

• The film coefficients given in Figure No.

4 include an allowance for fouling.

• From Figure No.4 we take

U= 30 W/m2K

Figure No. 4 [6]](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-16-2048.jpg)

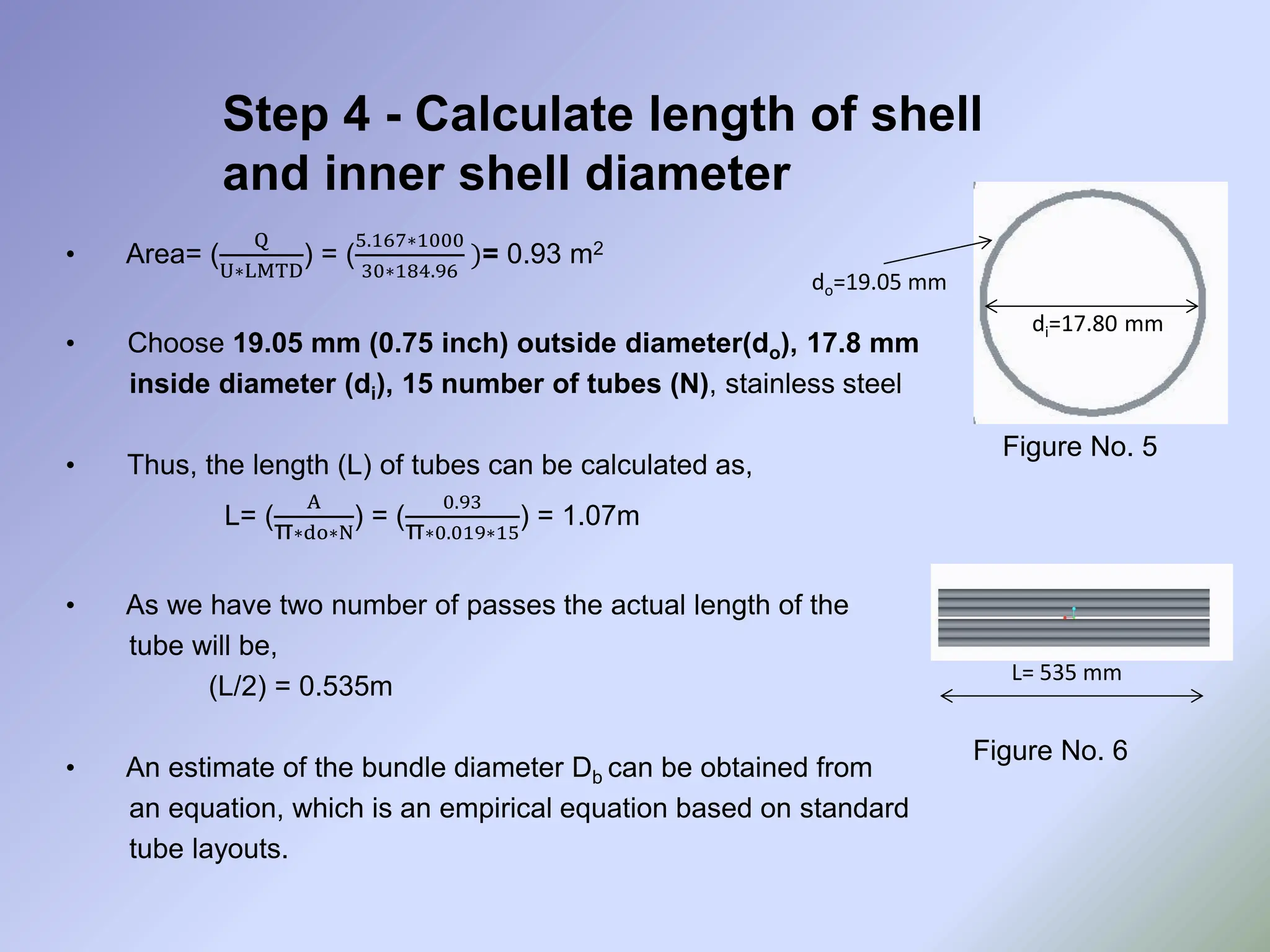

![Step 4 (Cont’d)

• The constants for use in this equation, for triangular and square patterns,

are given in Figure No. 7.

Db= (do* (

N

K1

)(

1

n

)

)

where Db= bundle diameter in mm, do = tube outside diameter in mm.,

N = number of tubes

• So, in our case we have:

Db= (0.019* (

15

0.249

)(

1

2.201

)

) = 0.122 m.

Figure No.7 [7]](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-18-2048.jpg)

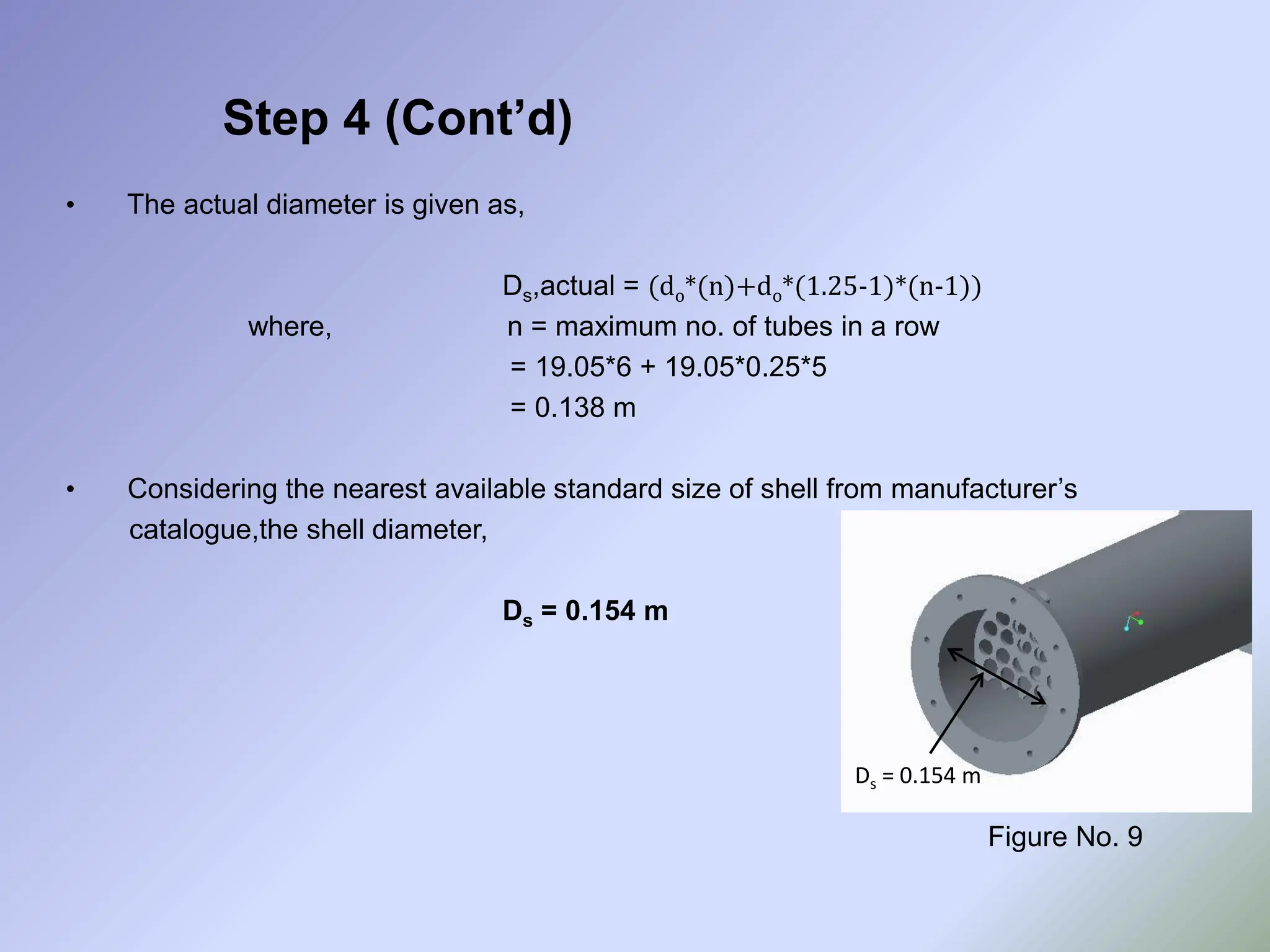

![Step 4 (Cont’d)

• Figure No.8 gives the graph from

where the bundle diameter can

be estimated for different types of

head.

• Shell diameter (Ds):

Ds = (Bundle diameter + Clearance)

= 0.122 + 0.0061

= 0.128 mm

• The actual bundle diameter, that

has been calculated by the

arrangement of tubes varies with that

of obtained from formula above.

Figure No. 8 [7]](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-19-2048.jpg)

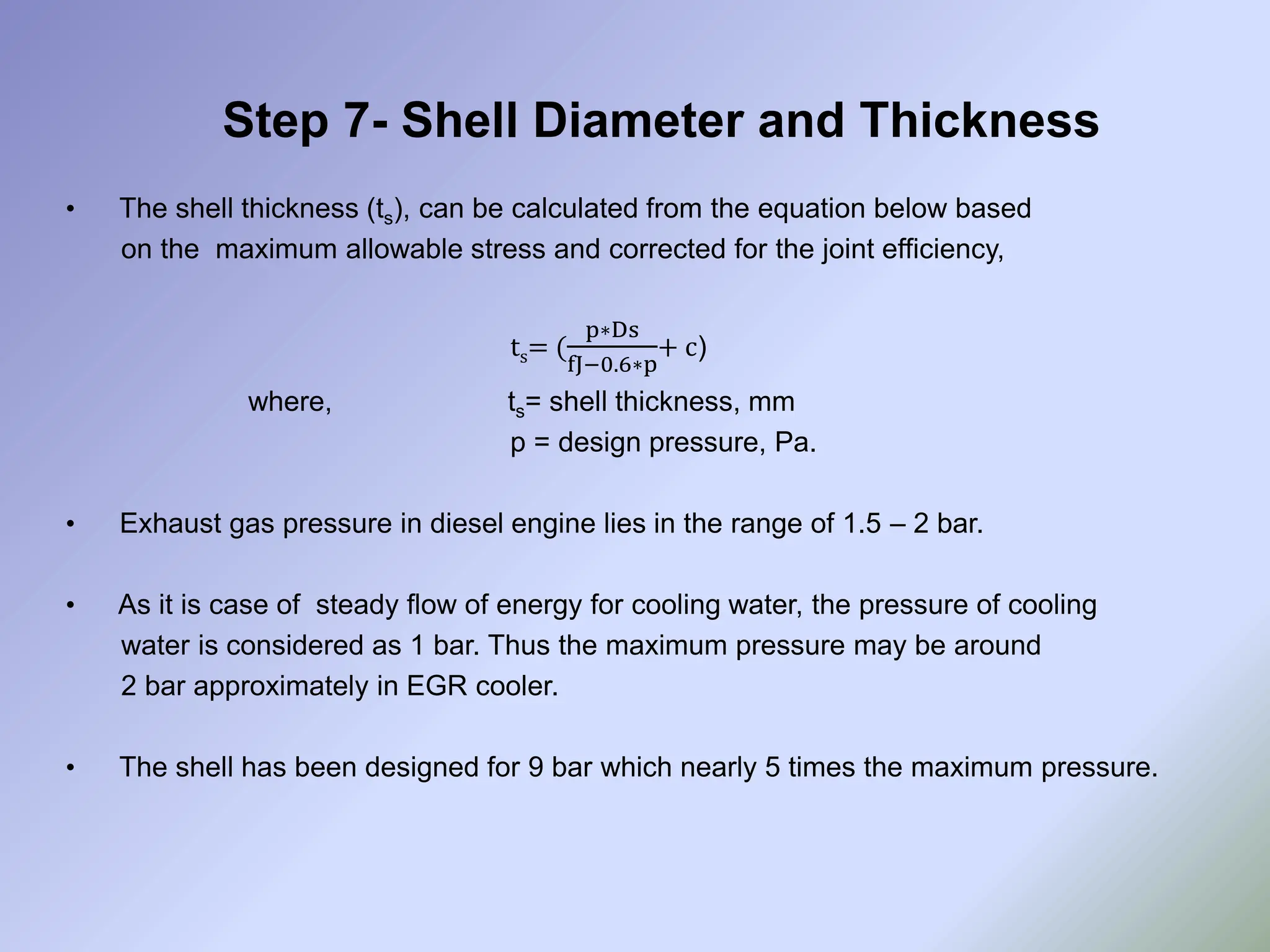

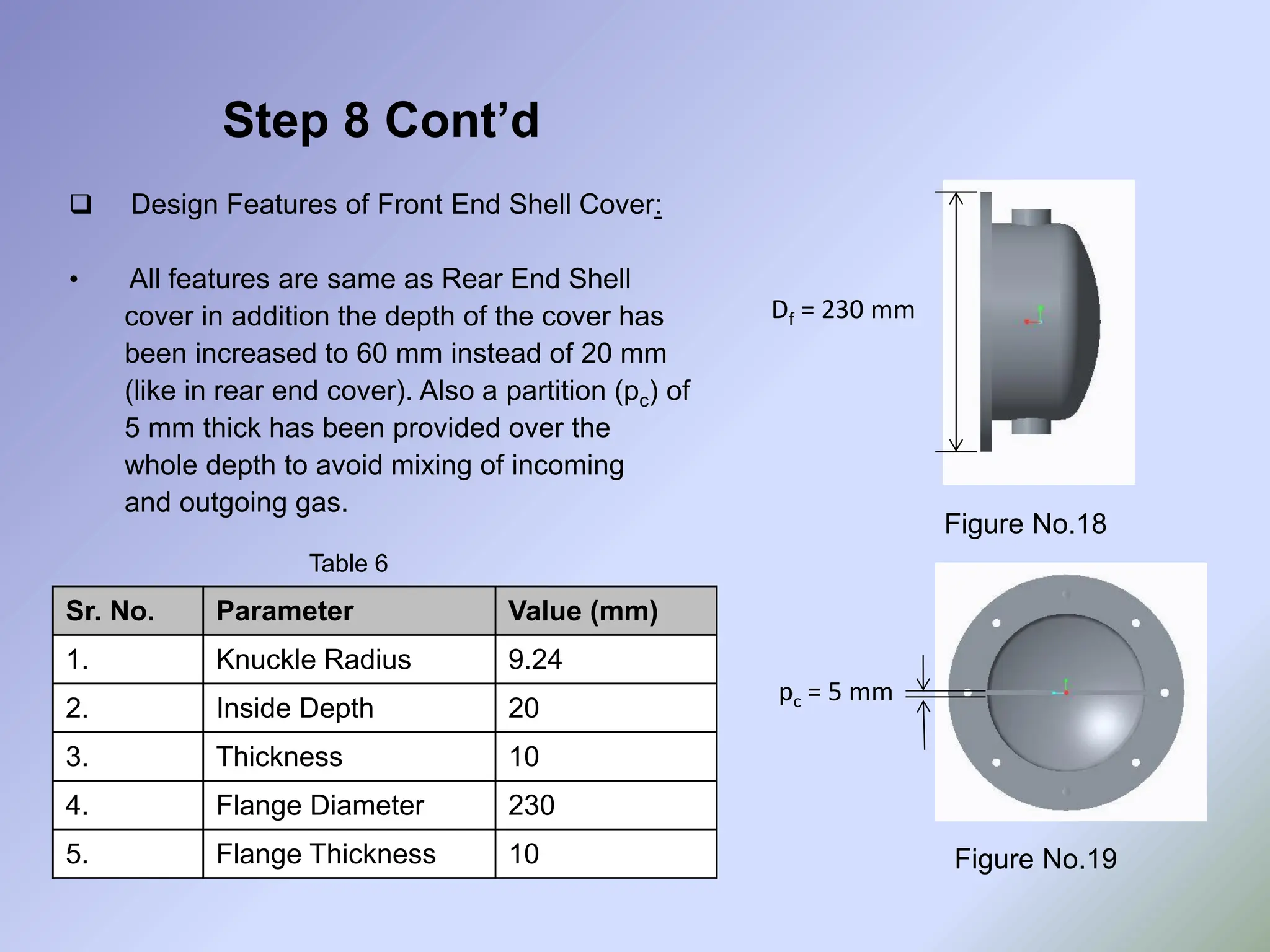

![Step 8- Front and End Cover

• Different types of shell covers such as flat, torispherical, hemispherical,

conical and ellipsoidal are used in shell and tube type of heat exchangers.

• Torispherical type is commonly used in chemical industries. Figure 15 shows the

various dimensions in it. We are considering the same in this case.

R = crown radius = Ds = 0.154 m

r = knuckle radius= (0.06*R)=0.00924 m

Hi= inside depth of head

= (R – {(R−

𝐷𝑠

2

) ∗ (R+

𝐷𝑠

2

) + 2∗r}(

1

2

)

)

= (154 – {(154−

154

2

) ∗ (154+

154

2

) + 2∗9.24}(

1

2

)

)

= 20.56 mm

Figure No. 15 [8]](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-32-2048.jpg)

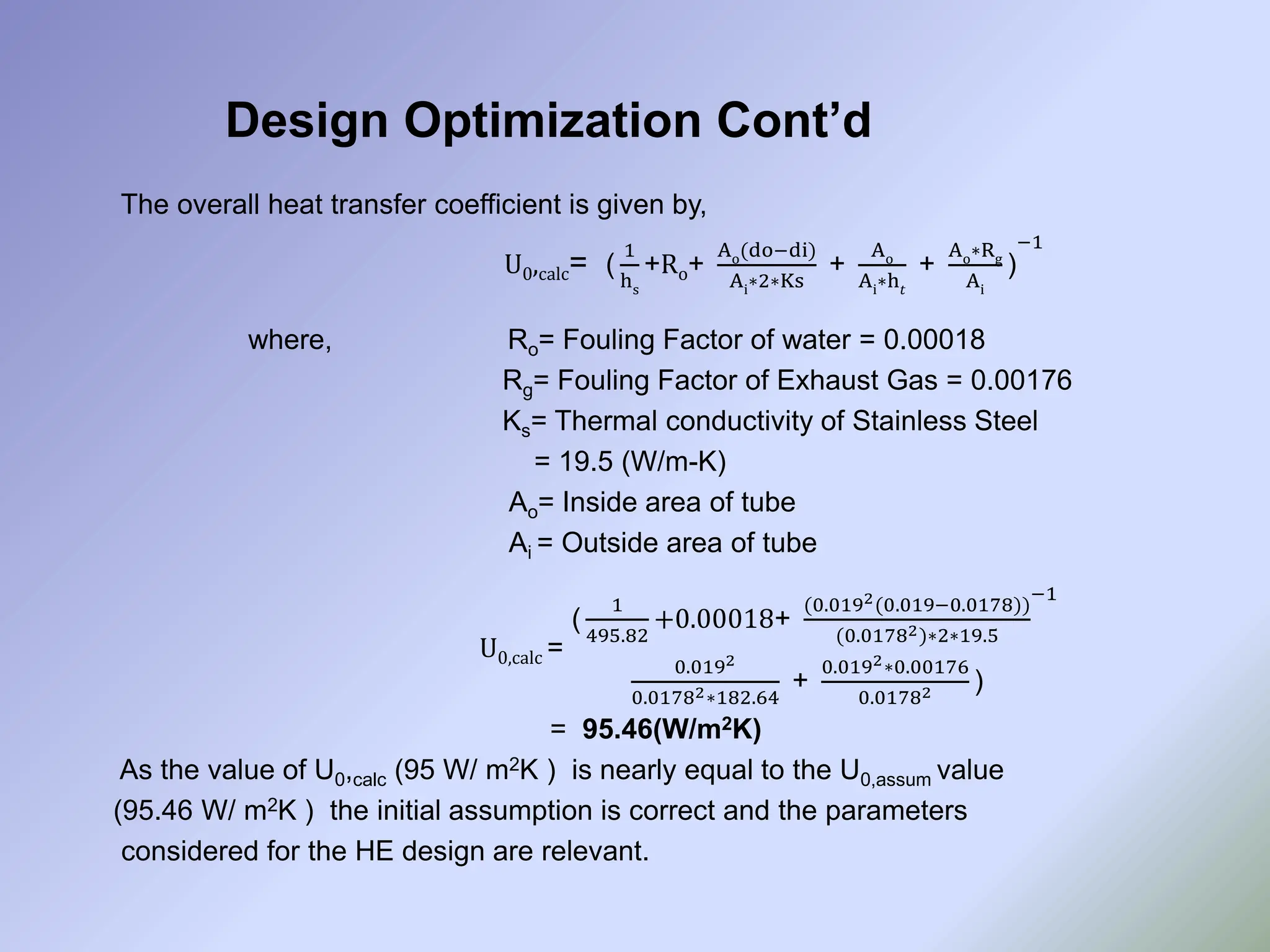

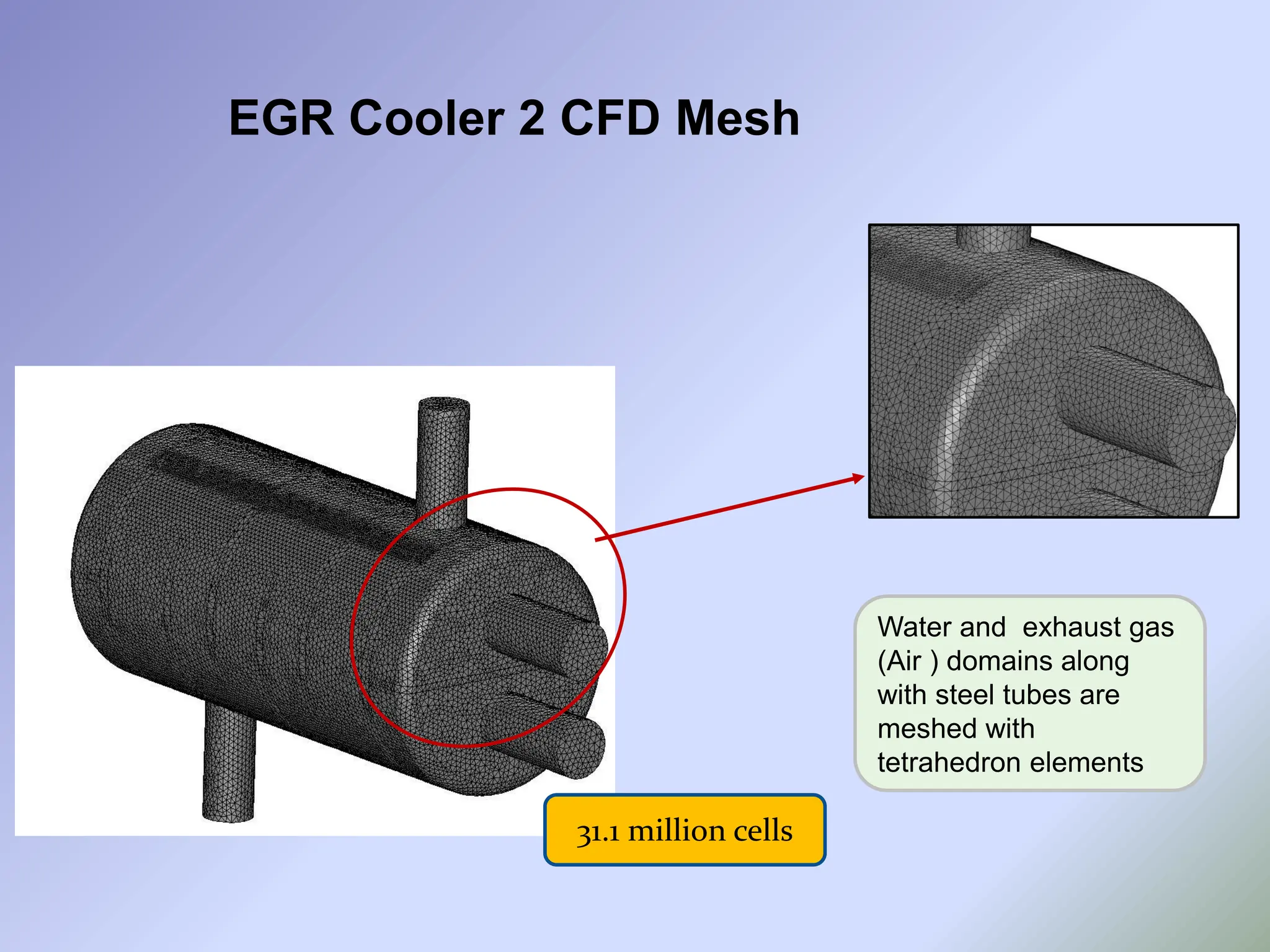

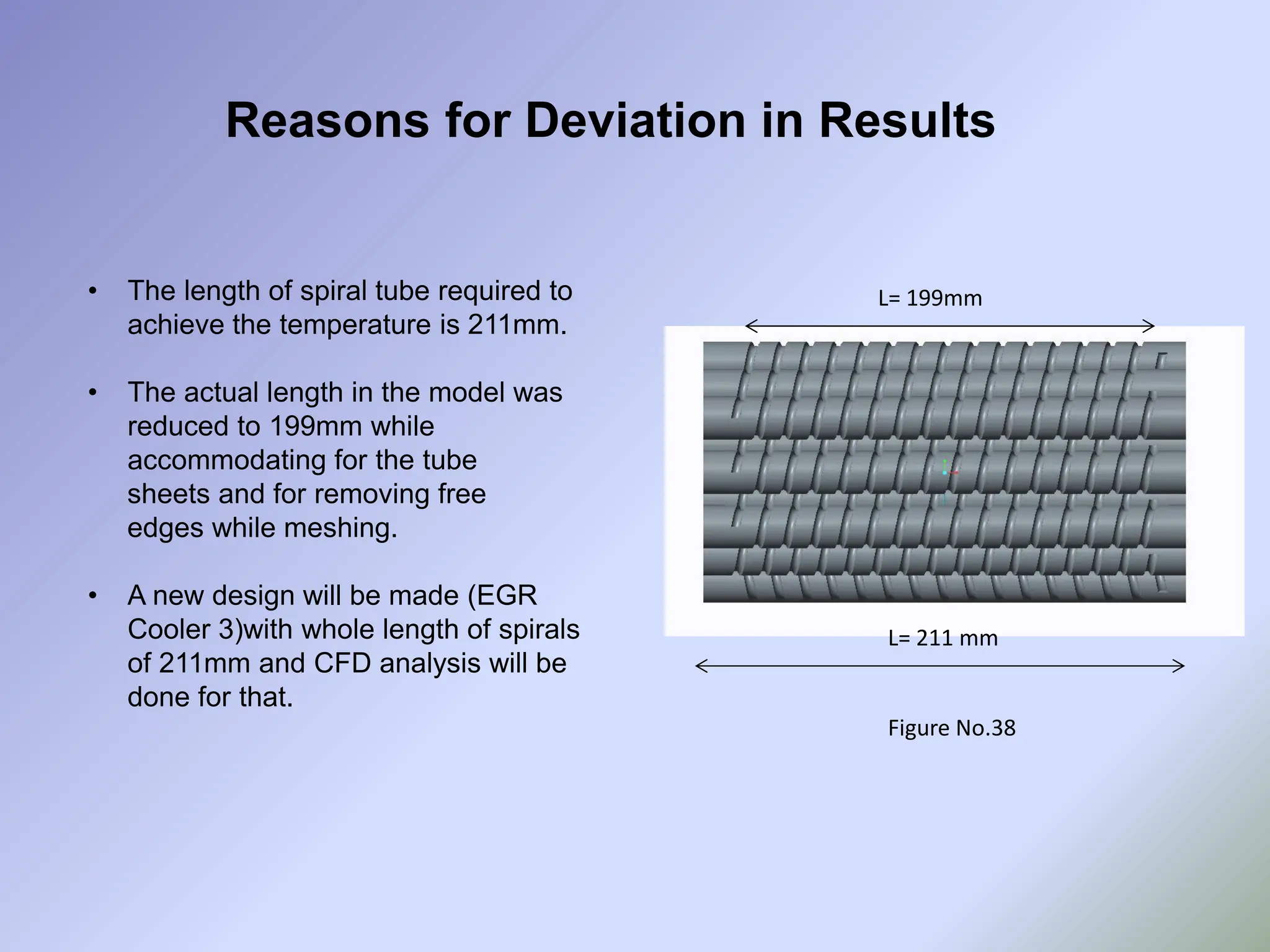

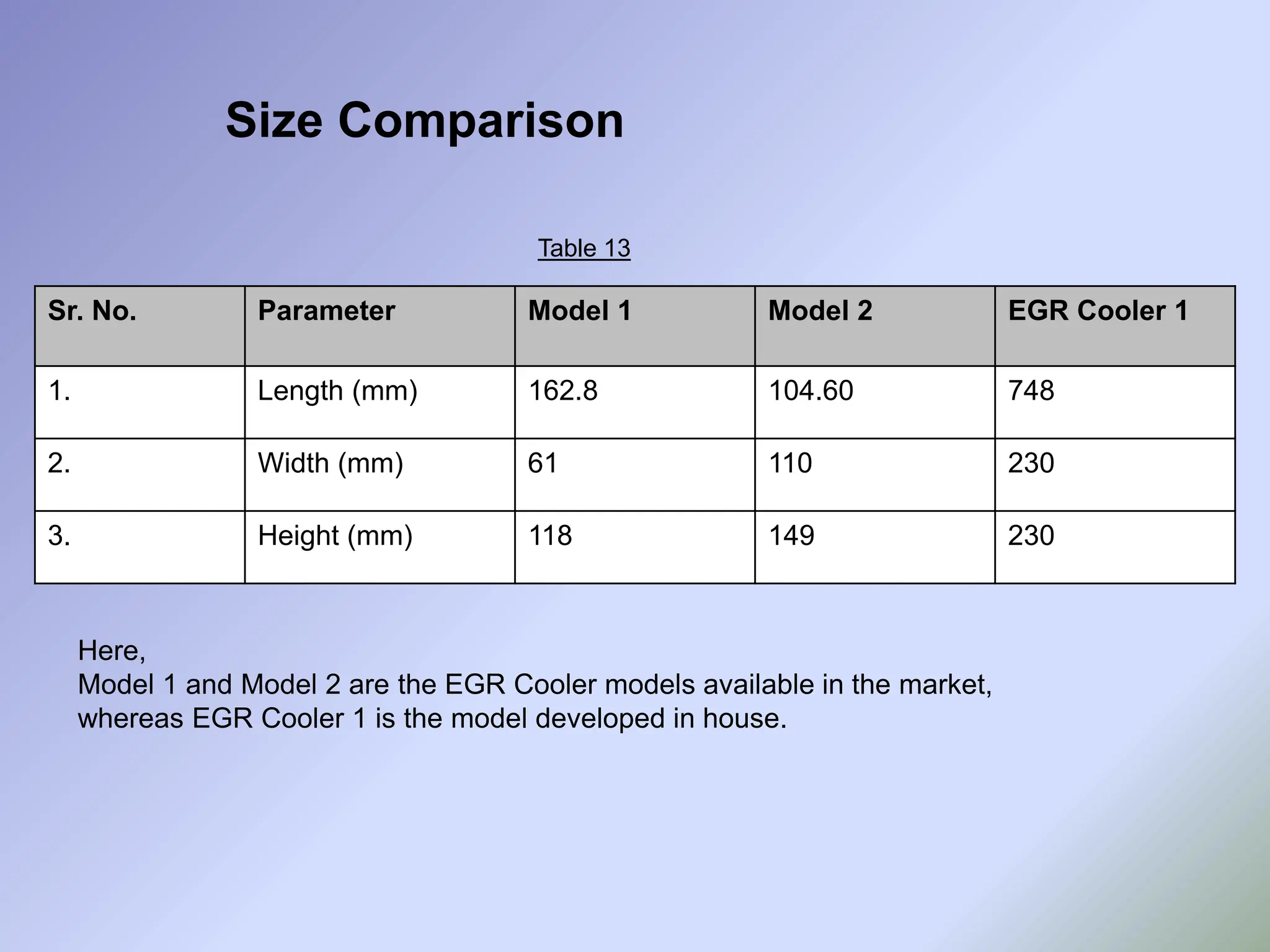

![• As it can be seen from earlier slides, though the designed EGR cooler gives satisfactory

performance, its way too bigger in size than the available models in the market. Thus

the optimization of the design is must.

• Reducing the size of EGR cooler maintaining the same performance is a

challenging task.

• Earlier research work done in this field depicts that use of corrugated tubes increases the

heat transfer coefficient [13] .

• The new EGR cooler has been designed with corrugated tubes instead of fully smooth

tubes, relevant calculated required are mentioned in next slides.

Design Optimization](https://image.slidesharecdn.com/egrcooleradityapatil2024-240829131047-e39a44cb/75/EGR-Cooler-Shell-and-Tube-Heat-Exchanger-Design-and-Simulation-analysis-56-2048.jpg)