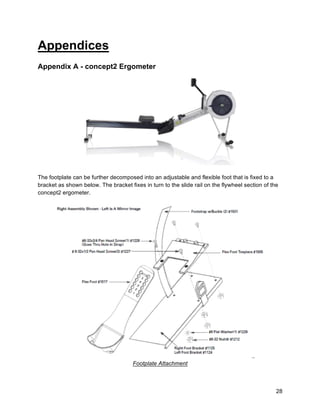

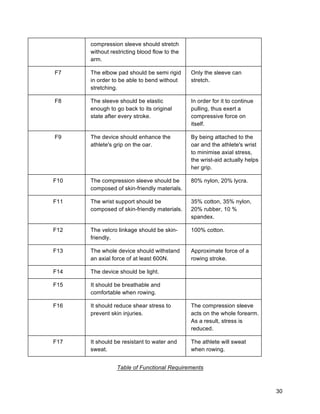

The document proposes designs for a wrist aid and footplate attachment for a rowing ergometer to accommodate athletes with limited joint range of motion. The wrist aid is intended to reduce force on the wrist of an athlete with arthritis. It would consist of straps and a compression sleeve to distribute force to the forearm. The rotating footplate aims to increase stroke length for an athlete with ankle bone spurs by allowing 12 more degrees of rotation. Calculations of forces exerted on wrists and feet during rowing informed the design requirements. Preliminary testing showed the devices could withstand non-cyclic loads but more testing is needed to confirm performance during intense training.