This document contains information from a reservoir simulation project. It includes:

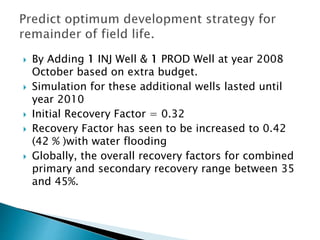

1. Names of team members and thanks to the project supervisor.

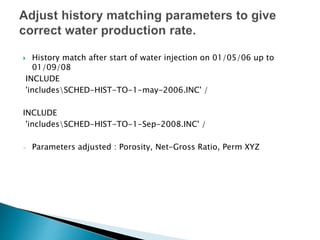

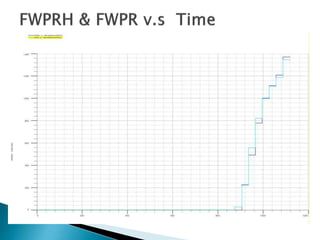

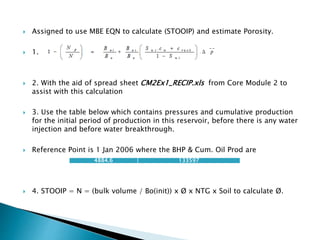

2. An assignment to calculate the original oil in place (OOIP) using material balance and estimate porosity, and match the water production rate in the history.

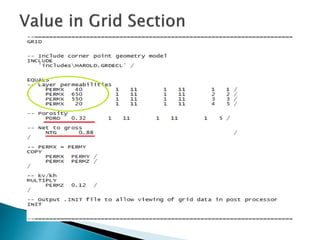

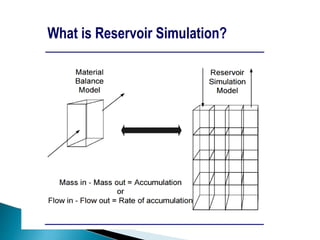

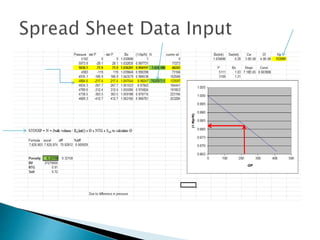

3. Details of the reservoir data, equations, and spreadsheets used to calculate OOIP and porosity.

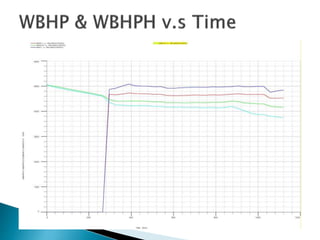

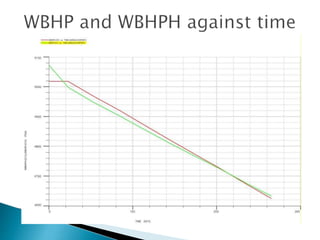

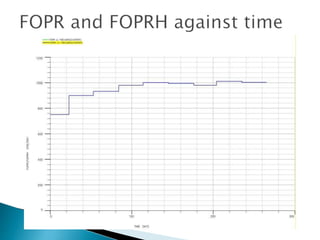

4. Comments that the model achieved a good history match for wellhead pressure and oil rate and that changes made to parameters like porosity and permeability were reasonable.

![ According to previous data, it has shown a

good match on the model.

Usually we determine a good match from

matching individual well RFT pressure,

individual well gas/oil ratio, water-cut and

shut-in pressure and avg Reservoir pressure

In Harold Case, we are able to match WBHP &

FOPR [ Line overlapping ]

With % diff only 0.000929](https://image.slidesharecdn.com/eclipsereservoirsimulationprojectpresentationslides-teamucsi-160731080456/85/Eclipse-reservoir-simulation-project-presentation-slides-team-ucsi-14-320.jpg)

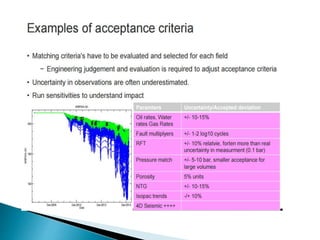

![ Several ways to decide if a match is satisfactory. If a

coarse study is being performed, the quality of the

match between observed and simulated parameters

does not need to be as accurate as it would be for a

more detailed study.

If the model has a good match but the changes made

were not realistic, then the model results should be

viewed with skepticism.

[ Changes in Harold case are reasonable ]

Ultimate objective of reservoir simulation is not

achieving a history match; it is being able to

reasonably predict the future performance of the

reservoir. The history match is only an intermediate

step in the modeling process.](https://image.slidesharecdn.com/eclipsereservoirsimulationprojectpresentationslides-teamucsi-160731080456/85/Eclipse-reservoir-simulation-project-presentation-slides-team-ucsi-15-320.jpg)