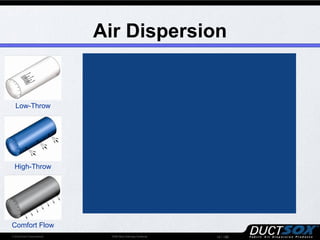

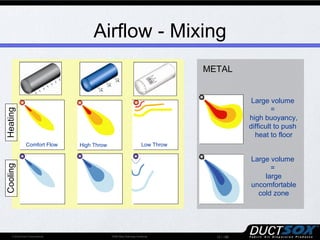

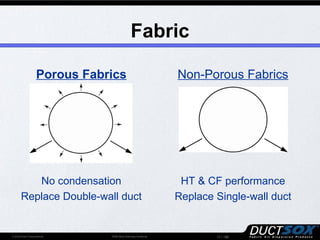

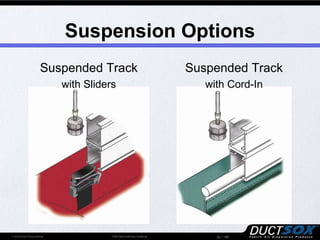

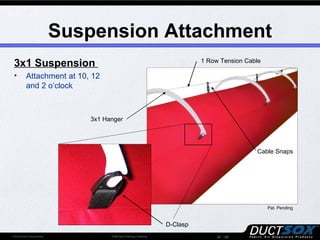

Fabric ducts like DuctSox are lightweight textile air dispersion products that provide advantages over metal ducts for applications in open ceiling architecture, critical environments, and under floor ventilation. They are easier and less expensive to install than metal ducts, absorb noise, prevent condensation, and come in various colors. DuctSox products come in different shapes and styles to provide even air dispersion, mixing, or targeted throw. They can be suspended from tracks or surface mounted and are made from antimicrobial fabrics to inhibit bacteria and mold growth.