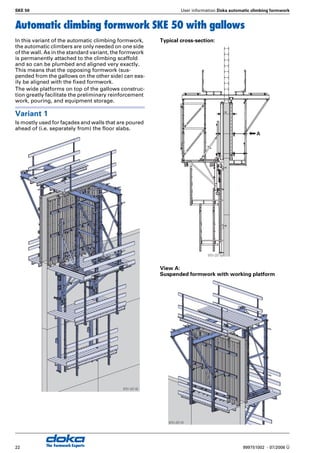

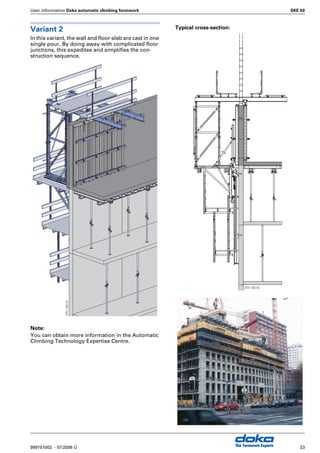

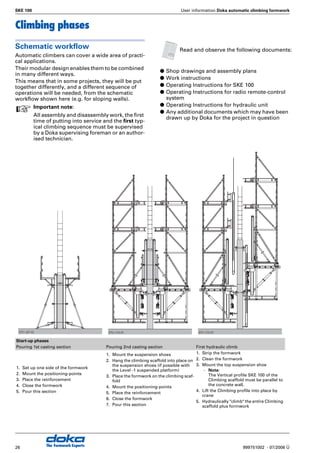

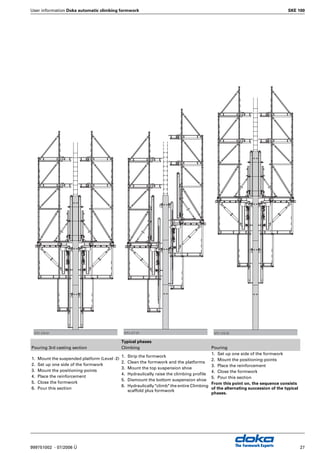

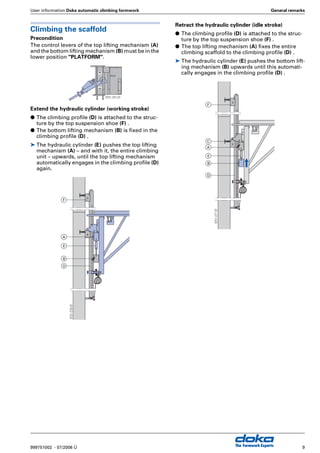

The document provides information on Doka automatic climbing formworks SKE 50 and SKE 100. It describes the systems, functional principles, hydraulic systems, anchoring methods, and climbing phases. The automatic climbers can simultaneously raise large formwork elements and climbing scaffolds in one step without a crane. Safety is the top priority in all work phases.

![User information Doka automatic climbing formwork SKE 50

17999751002 - 07/2006 Ü The Formwork Experts

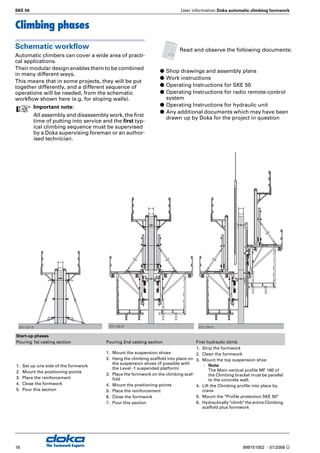

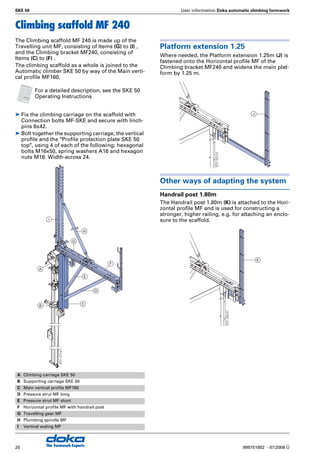

Automatic climber SKE 50

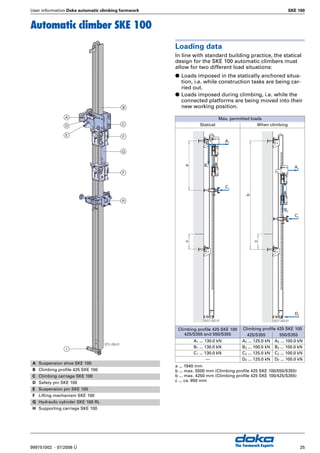

Loading data

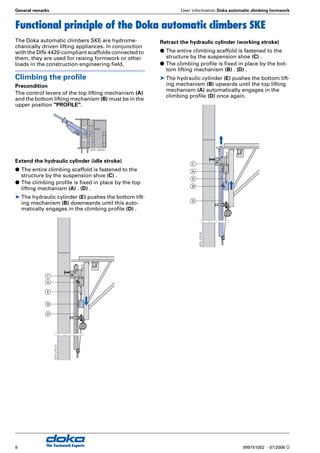

In line with standard building practice, the statical

design for the SKE 50 automatic climbers must

allow for two different load situations:

G Loads imposed in the statically anchored situa-

tion, i.e. while construction tasks are being car-

ried out.

G Loads imposed during climbing, i.e. while the

connected platforms are being moved into their

new working position.

a ... 1494 mm

b ... max. 5500 mm (Climbing profile SKE 50/550/S355)

b ... max. 4250 mm (Climbing profile SKE 50/425/S355)

c ... ca. 700 mm

A Suspension shoe SKE 50 rigid

B Climbing profile SKE 50

C Climbing carriage SKE 50

D Safety pin SKE 50

E Suspension pin SKE 50

F Lifting mechanism SKE 50, top

G Hydraulic cylinder SKE 50 RL

H Lifting mechanism SKE 50, bottom

I Supporting carriage SKE 50

J Supporting shoe SKE 50

K Profile protection plate SKE 50 top

L Profile protection SKE 50

M Profile protection plate SKE 50 bottom

M

L

K

I

J

E

D

A

B

C

F

G

H

9751-213-01

Max. permitted loads

Statical When climbing

A2 ... 55.0 kN

B2 ... 50.0 kN

C1 ... 69.0 kN C2 ... 33.0 kN

— D2 ... 21.2 kN

Max. permitted loads (statical)

B1[kN]

A1 [kN]

A1

B1

C1

a

9218-235-01

c

A2

D2

C2

B2

b

9218-236-01

c

9218-100

100

80

60

40

20

0

0 20 40 60 80](https://image.slidesharecdn.com/dokaselfclimbingsystem-140411063741-phpapp02/85/Doka-self-climbing-system-21-320.jpg)