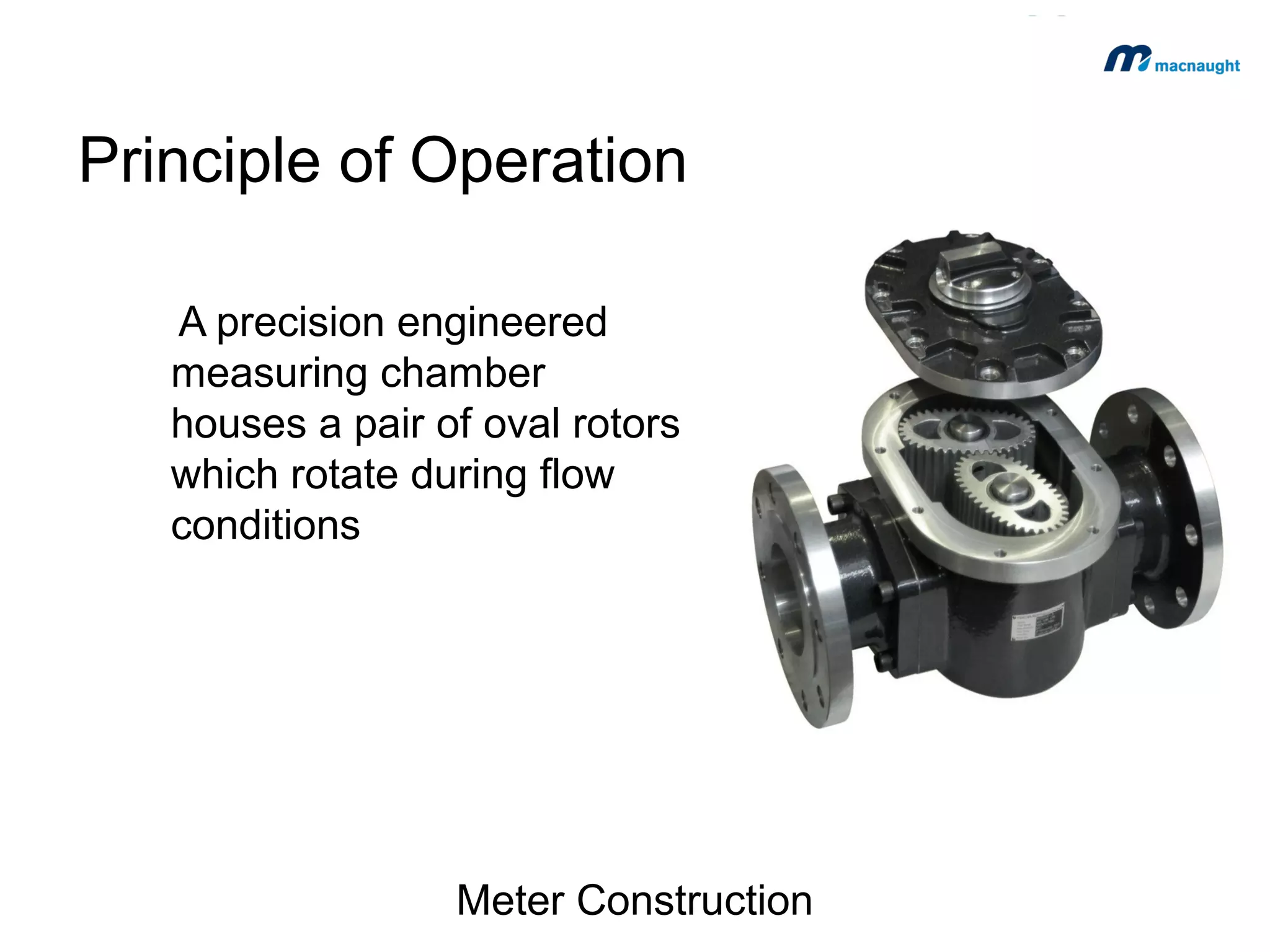

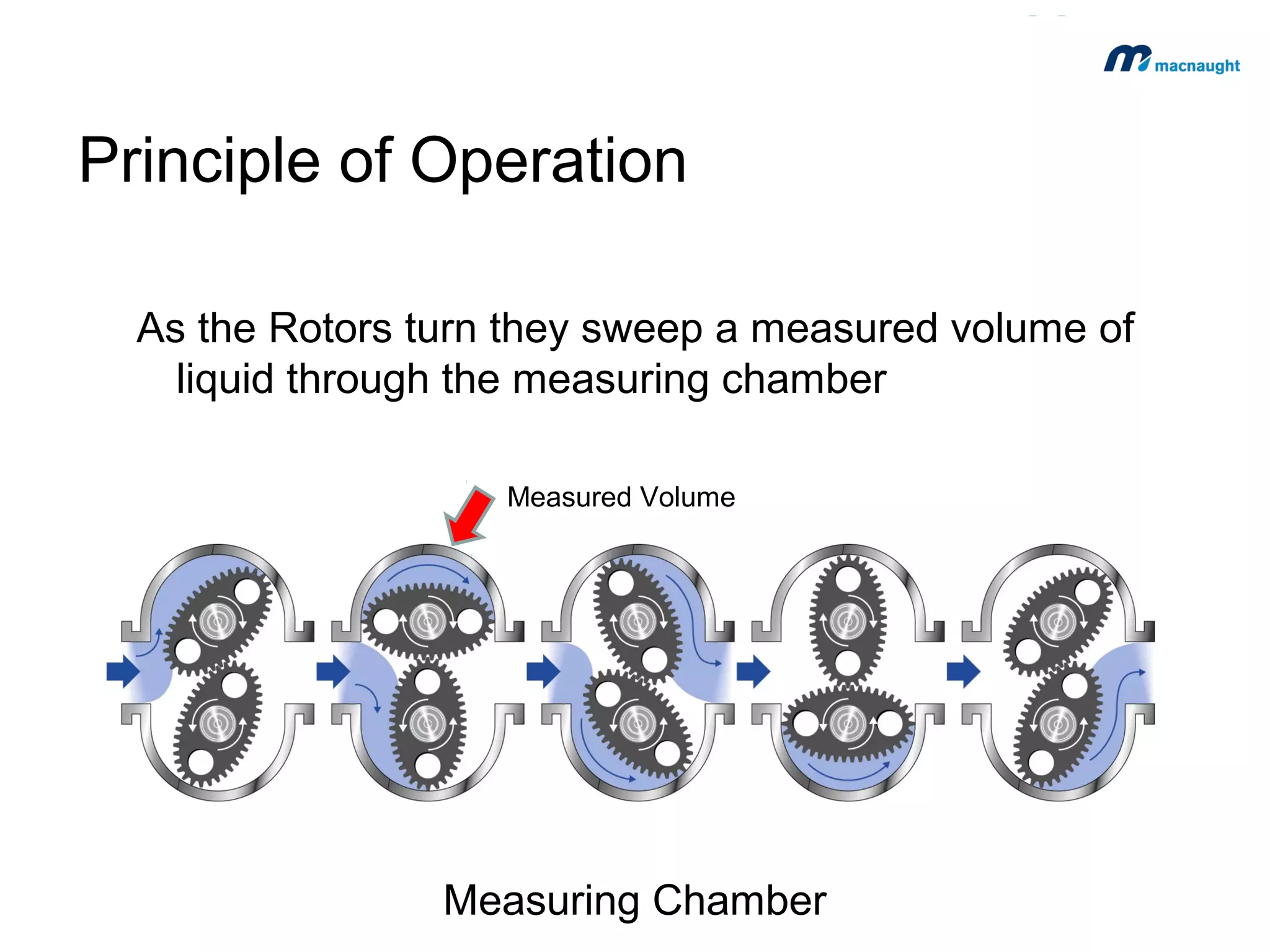

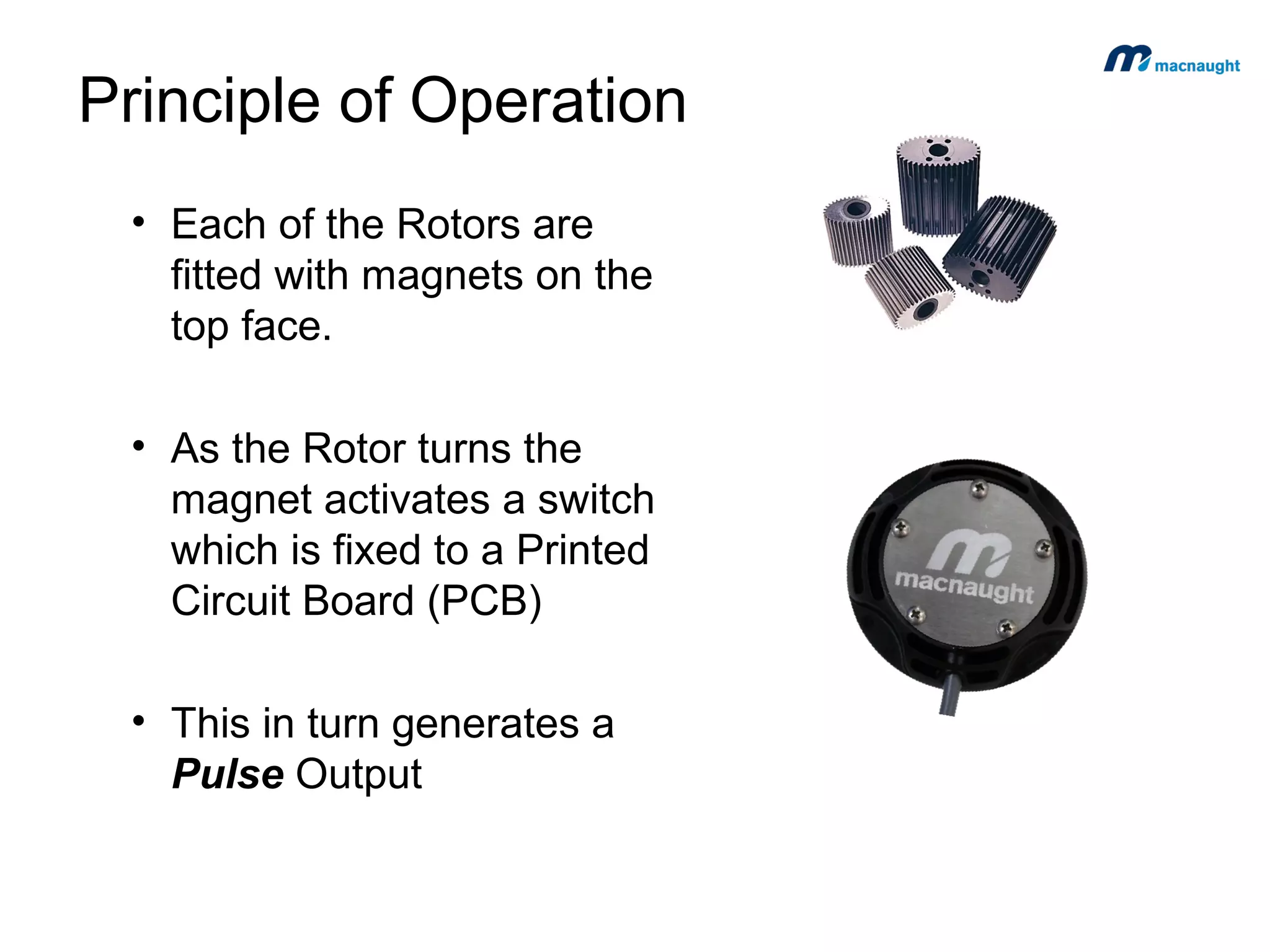

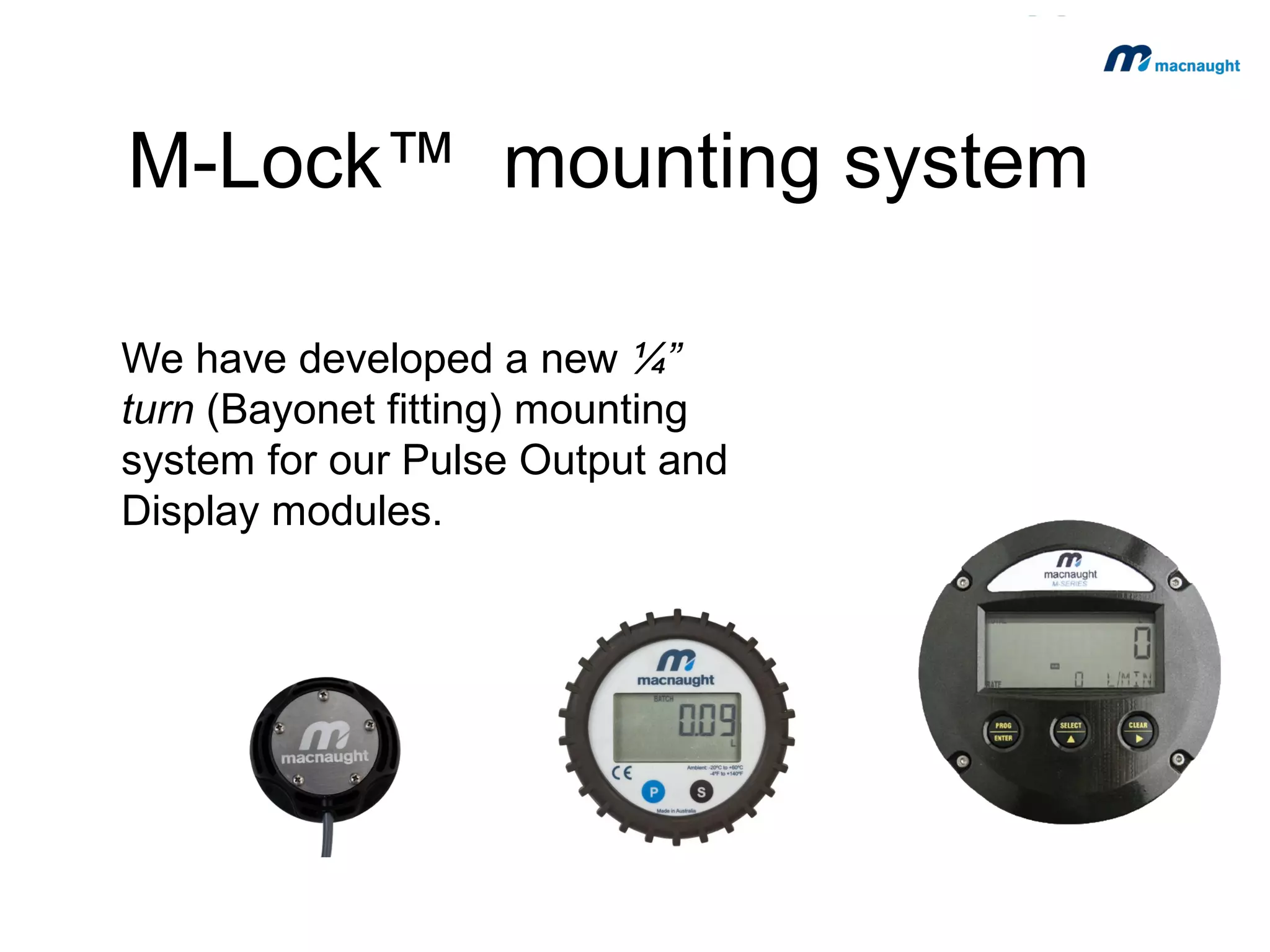

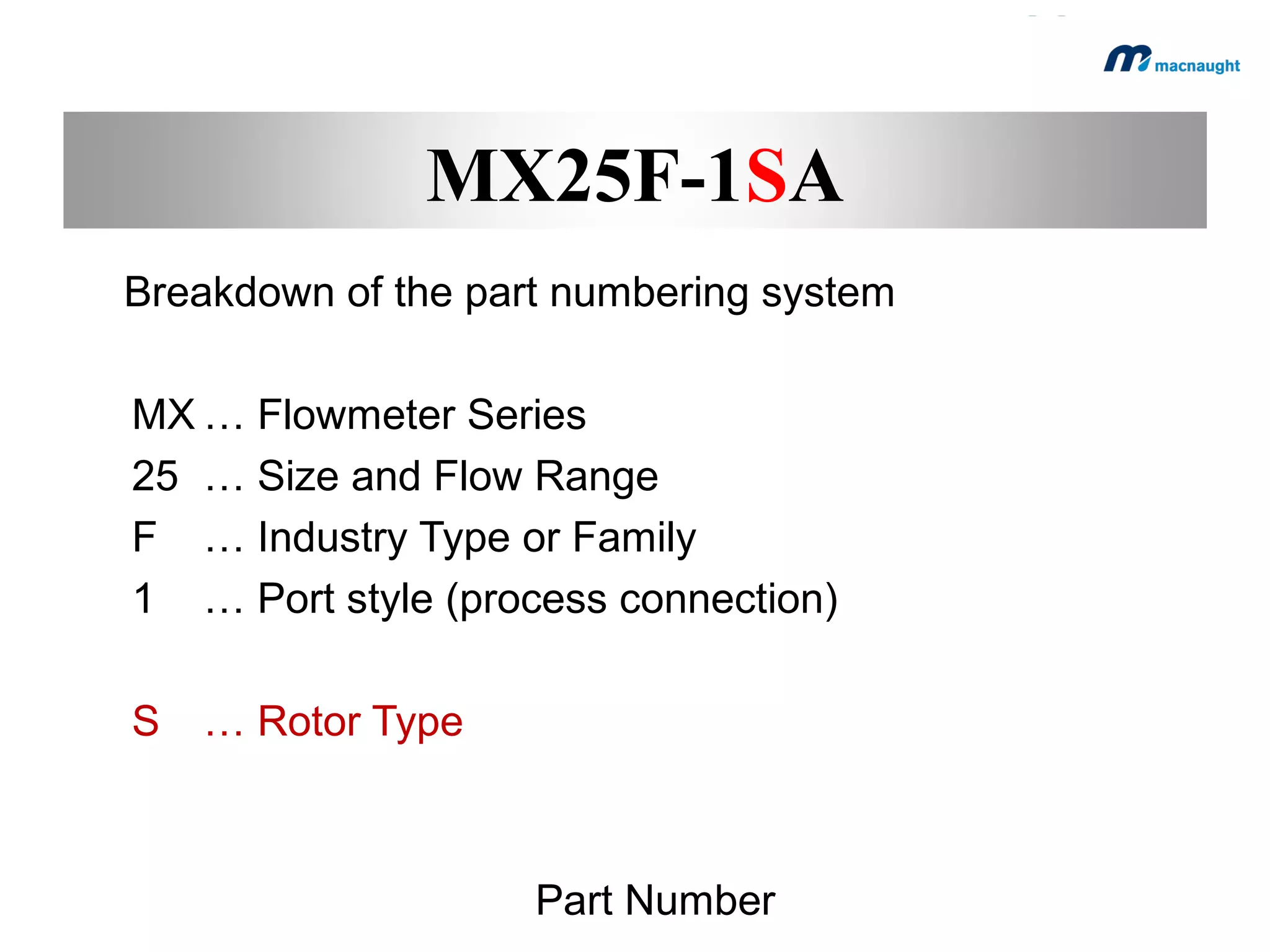

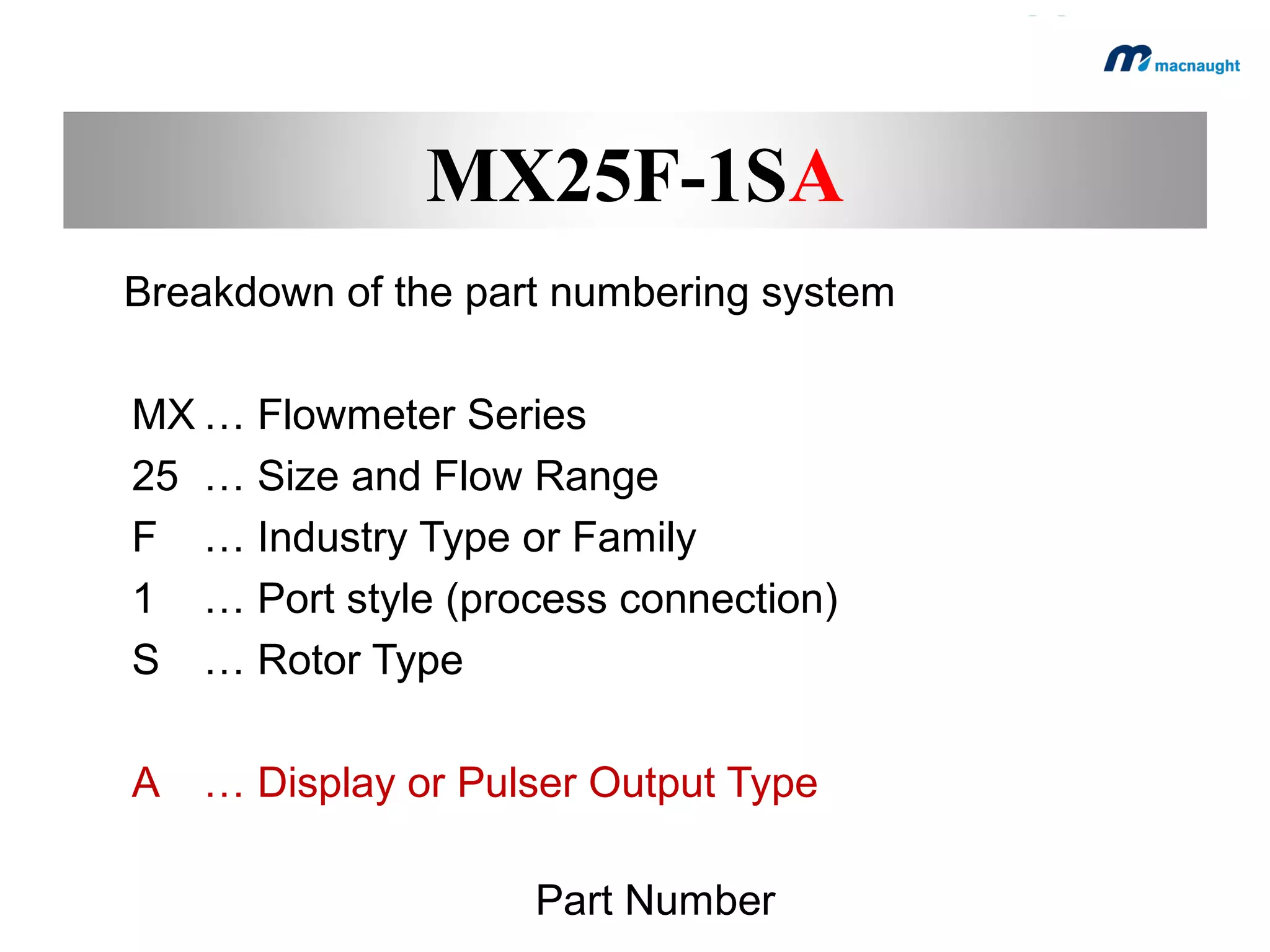

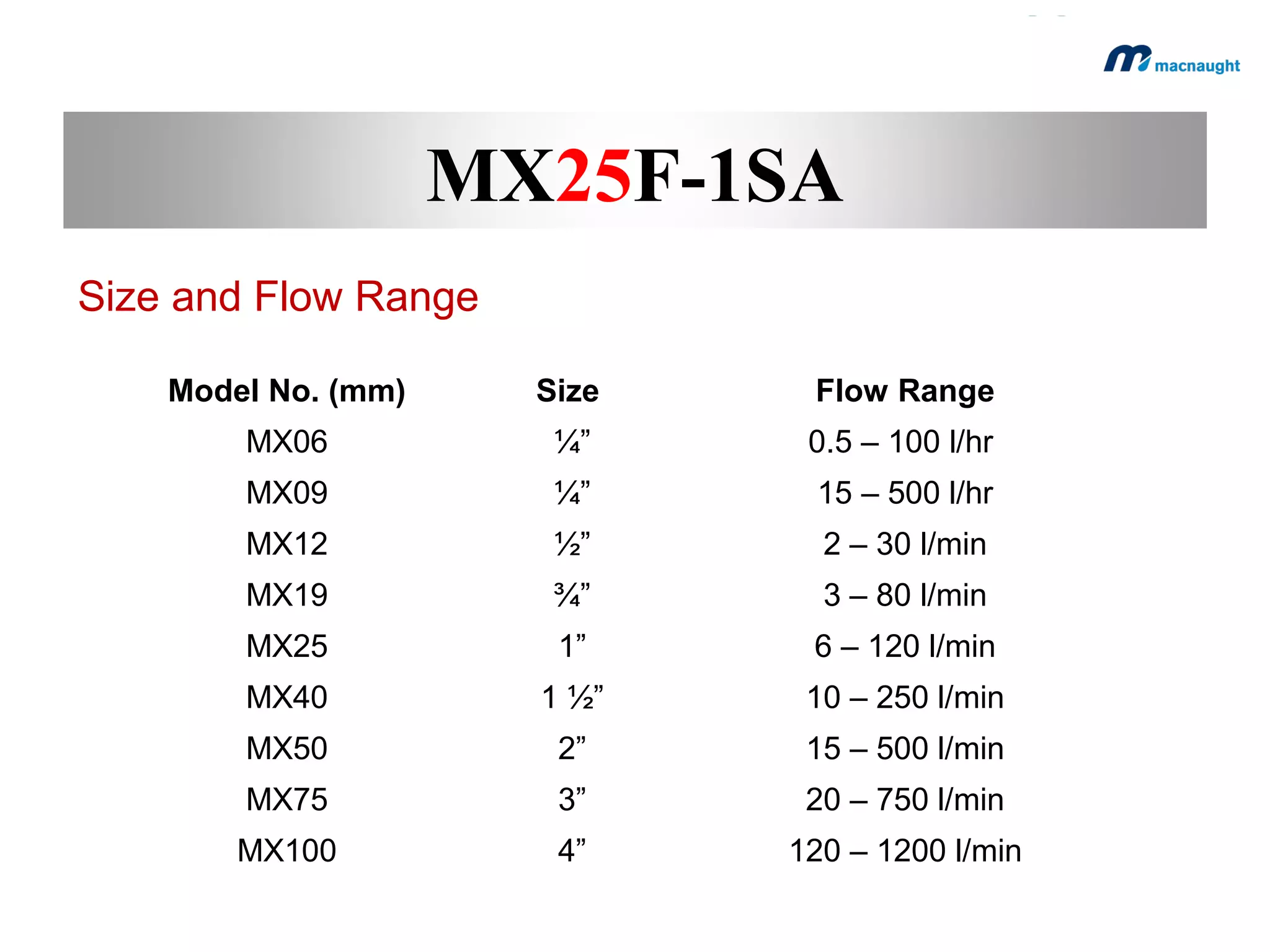

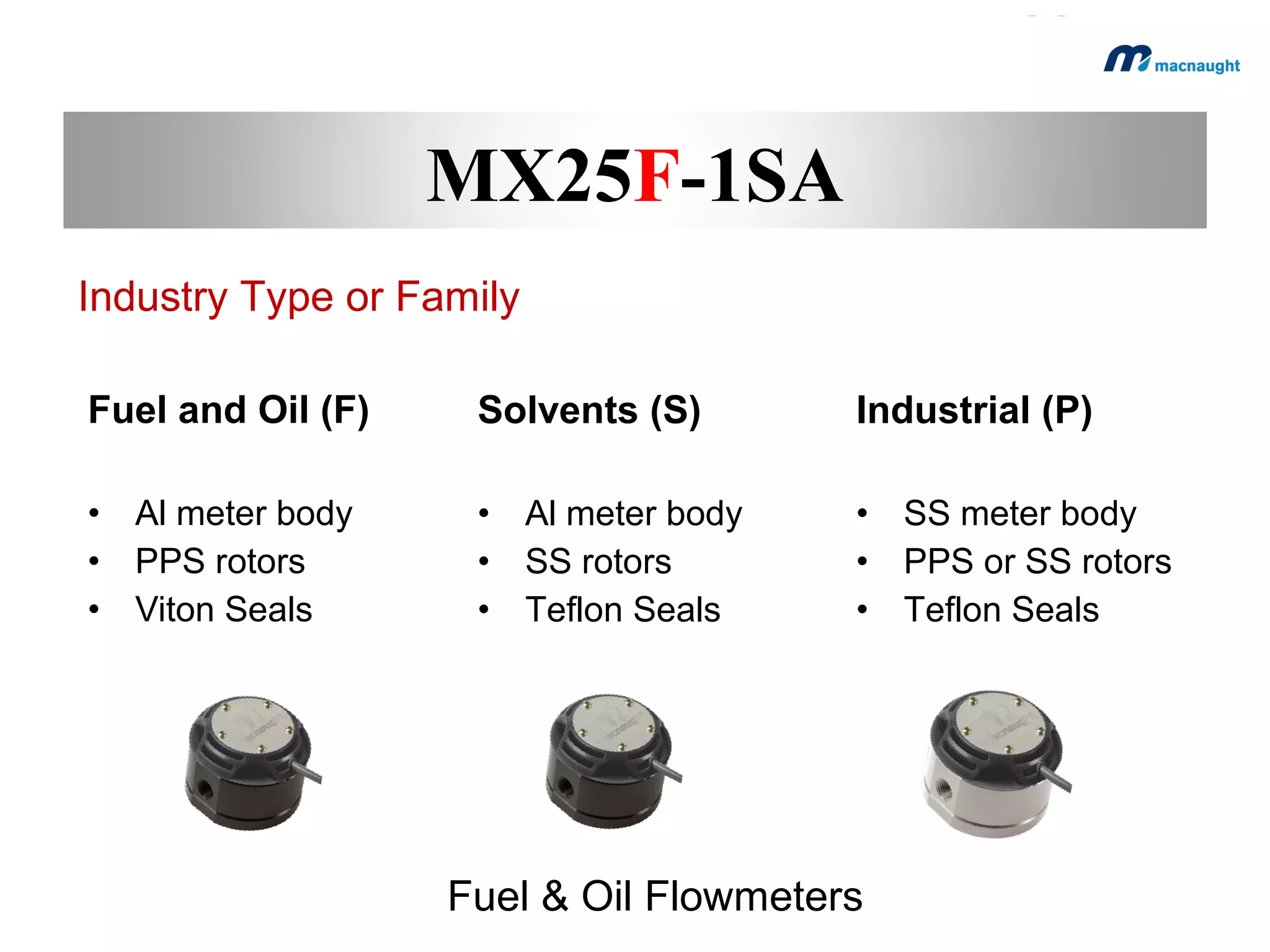

The document provides an overview of flow meter technologies, with a focus on positive displacement flow meters. It discusses the principles of operation for positive displacement meters, including how they directly measure volume by passing measured volumes of fluid through a measuring chamber. The document also outlines applications for positive displacement meters like batching and dispensing. It introduces the new MX series of positive displacement flow meters from Macnaught, highlighting features like increased temperature and pressure ratings, a new mounting system, and hazardous area approvals.