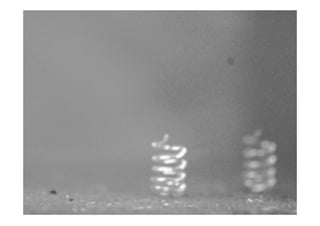

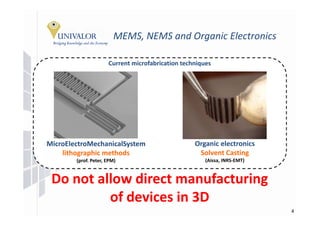

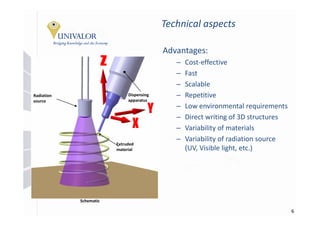

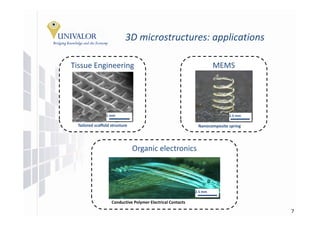

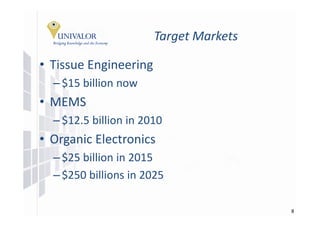

The document describes a direct 3D microfabrication process developed by researchers at Ecole Polytechnique de Montreal and INRS. It allows for cost-effective, fast, scalable manufacturing of 3D microstructures using a variety of materials without the limitations of current techniques. The team is seeking partnerships for further development and commercialization, with target markets in tissue engineering, MEMS, and organic electronics estimated to be worth over $25 billion.