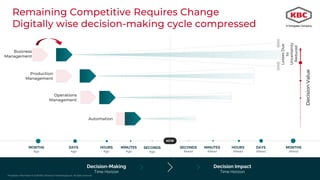

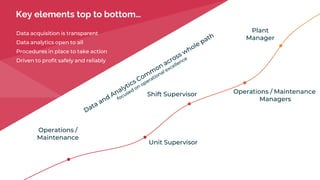

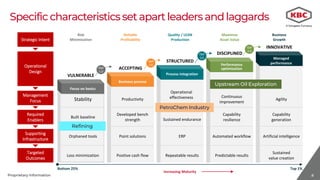

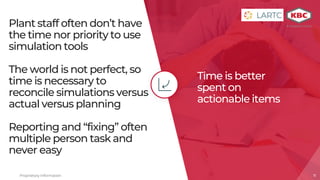

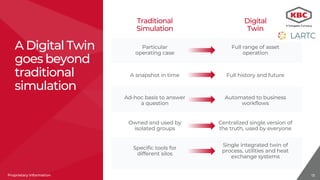

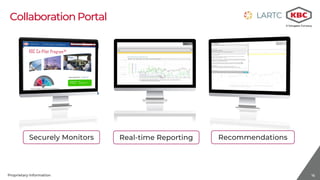

The document outlines KBC's digitalization strategy aimed at achieving operational excellence in energy and chemical process operations through effective data utilization and advanced technology integration. It emphasizes the importance of a digital twin for accurate simulations and real-time data collaboration, enhancing decision-making and performance management. The strategy also highlights the need for a culture of profitability, safety, and continuous improvement within organizations.