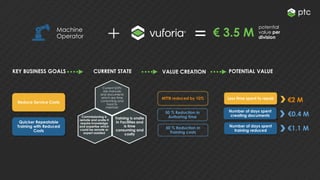

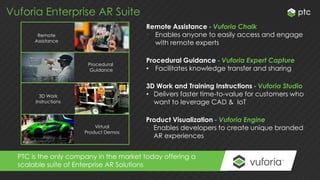

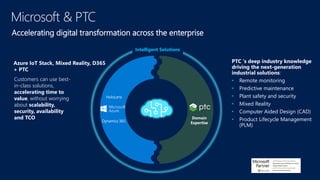

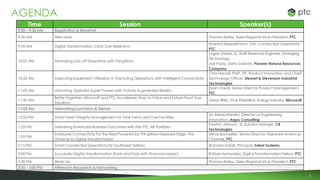

This document provides an agenda for a digital transformation event hosted by PTC. The agenda includes sessions on topics such as digital transformation strategies that executives can believe in, minimizing gas lift downtime using IoT technologies, improving equipment utilization in fracturing operations, unlocking operator capabilities with augmented reality, and accelerating time to value through partnerships between PTC and Microsoft. There will be presentations from PTC executives and customers on these topics, as well as networking sessions and demonstrations. The event aims to provide insights into how oil and gas companies can leverage digital technologies to improve operations and business outcomes.

![“Industrial companies [need] to

capitalize on digital technologies

to defend and advance their

competitive advantage.”

DIGITAL TRANSFORMATION’S TIME IS NOW

of skilled energy workers may retire in next years.

50%

Sharp oil price fluctuations

Create a cloud of uncertainty in upstream

and downstream investments](https://image.slidesharecdn.com/leadershipexchangehoustonsharedpresentations-200218154116/85/Leadership-Exchange-Houston-Shared-Presentations-9-320.jpg)