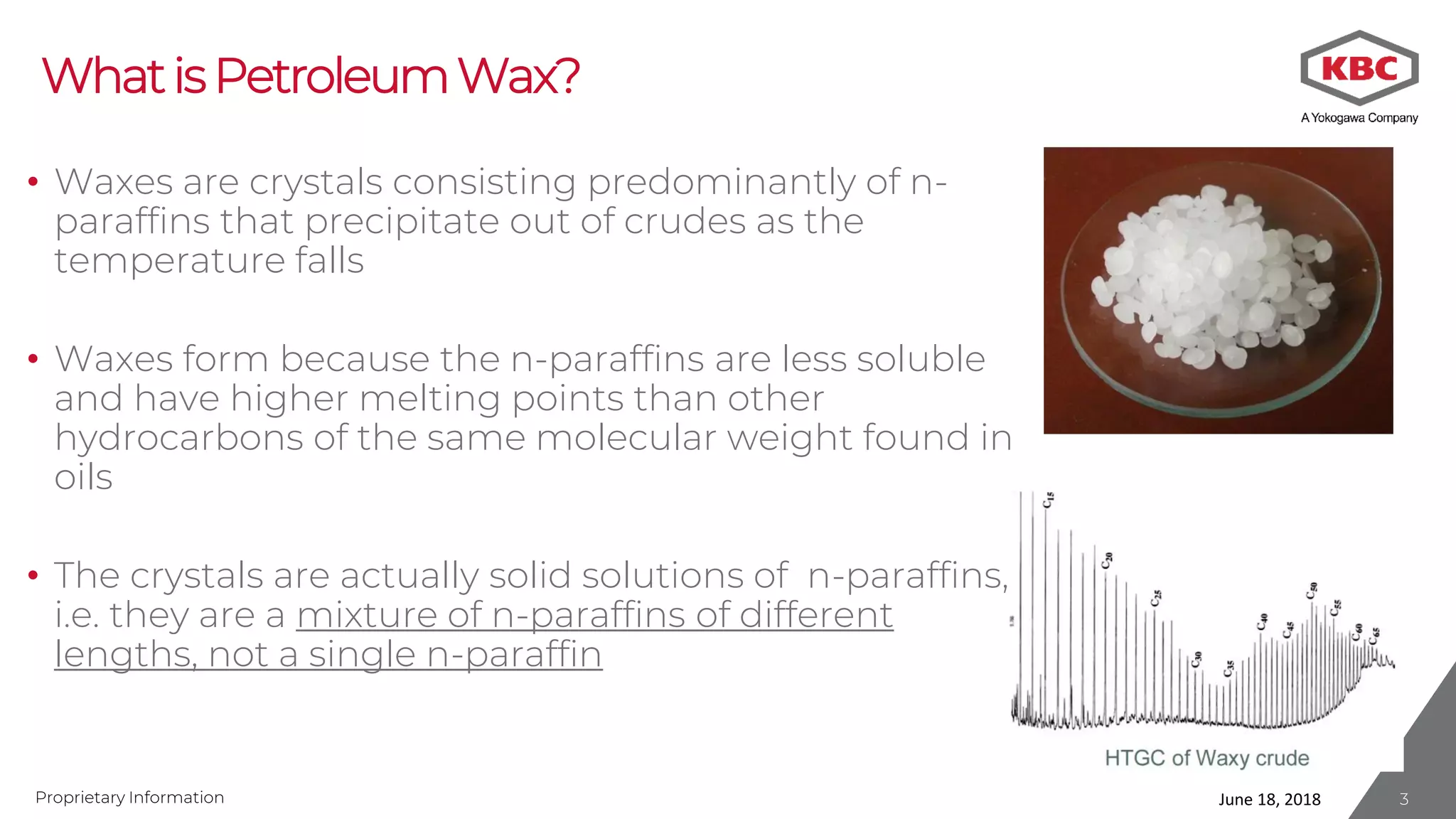

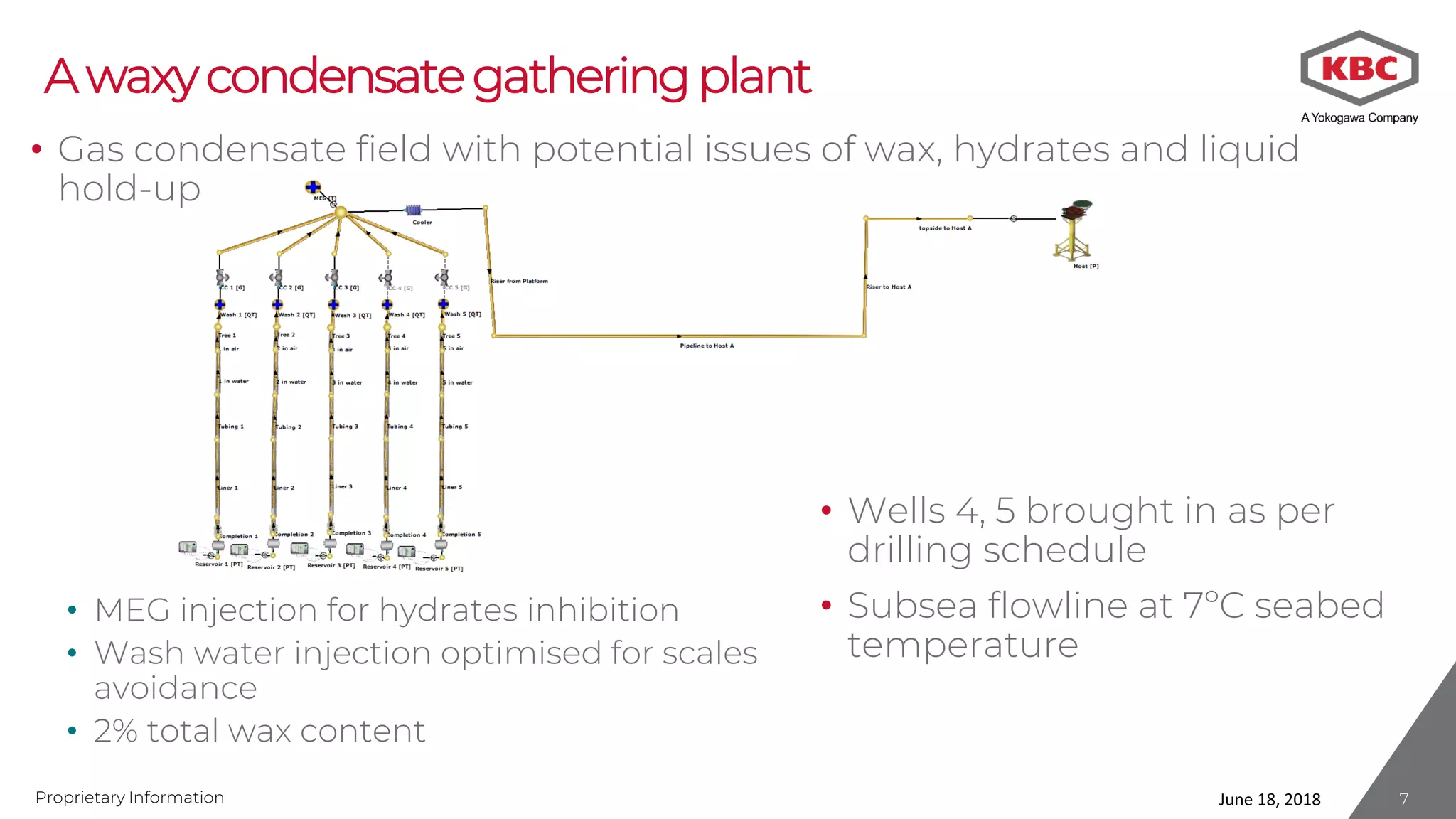

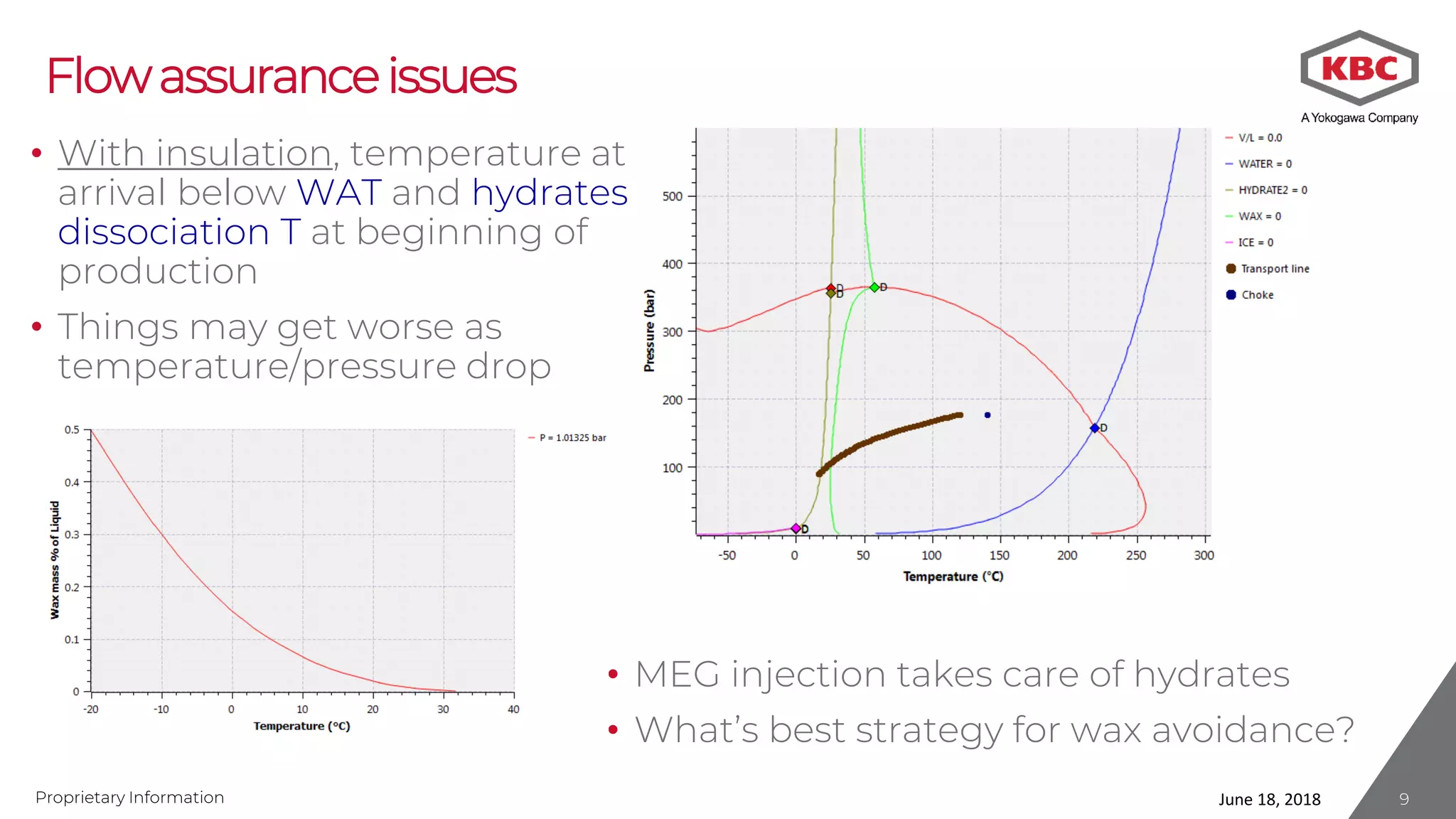

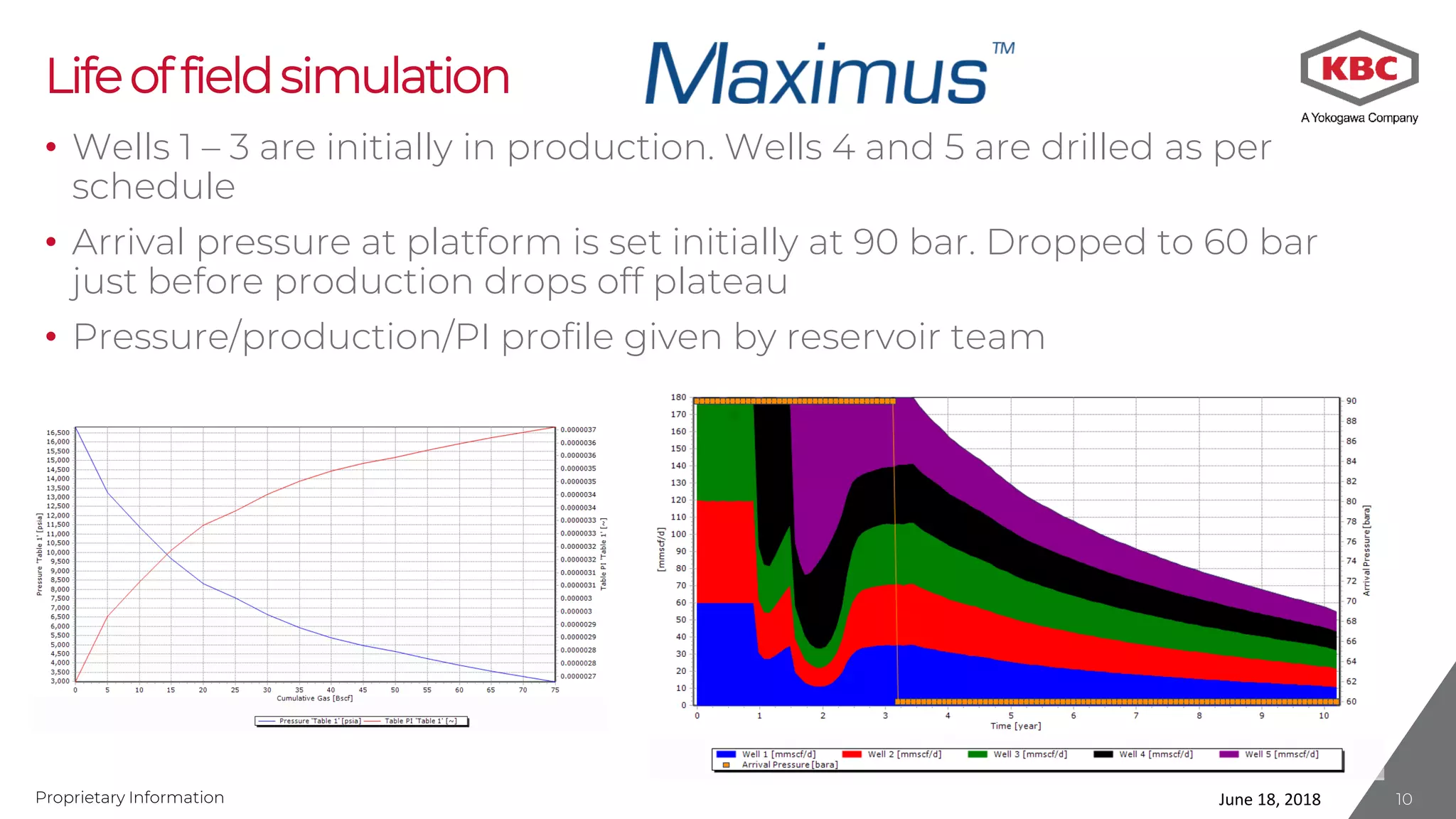

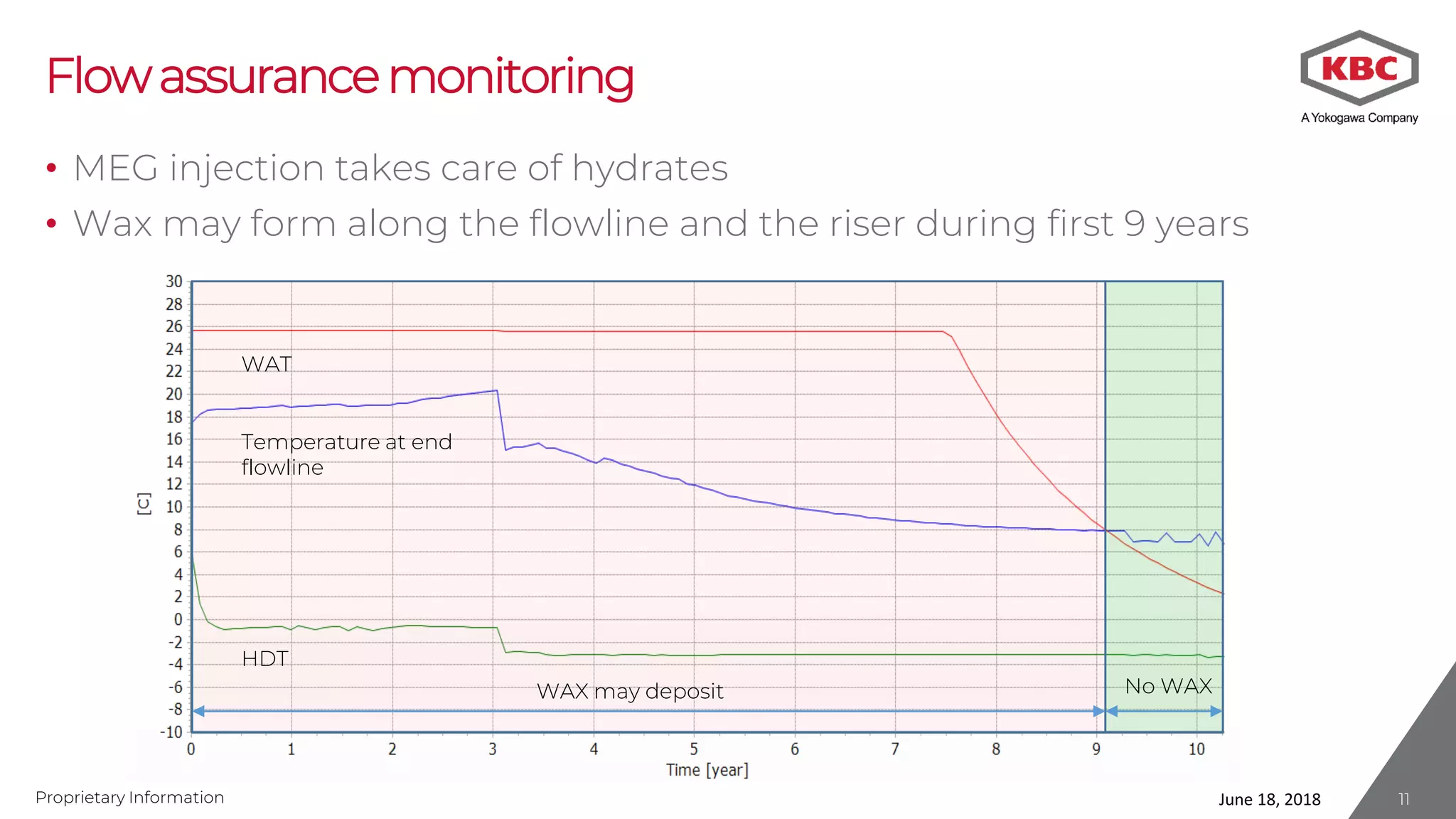

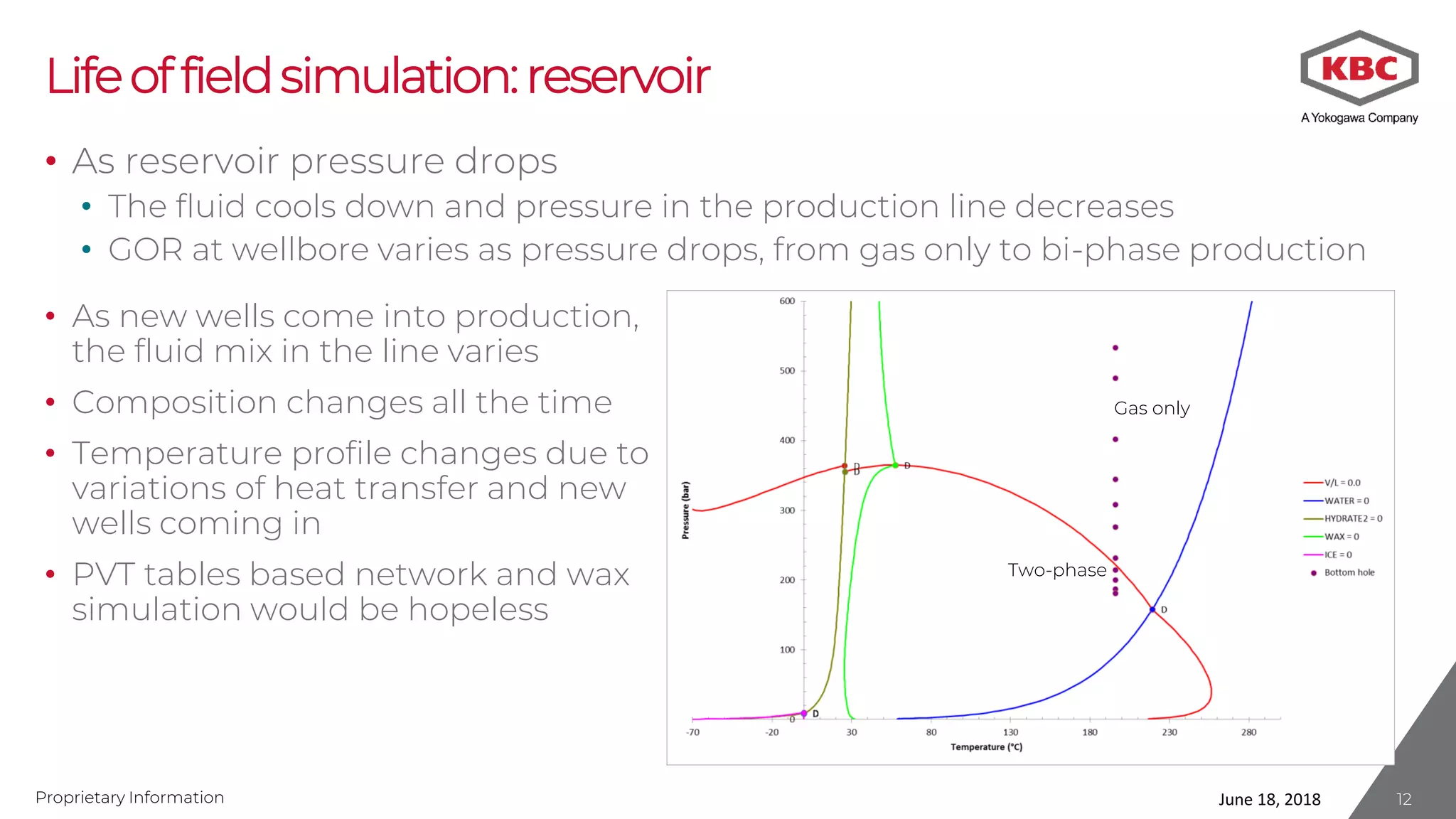

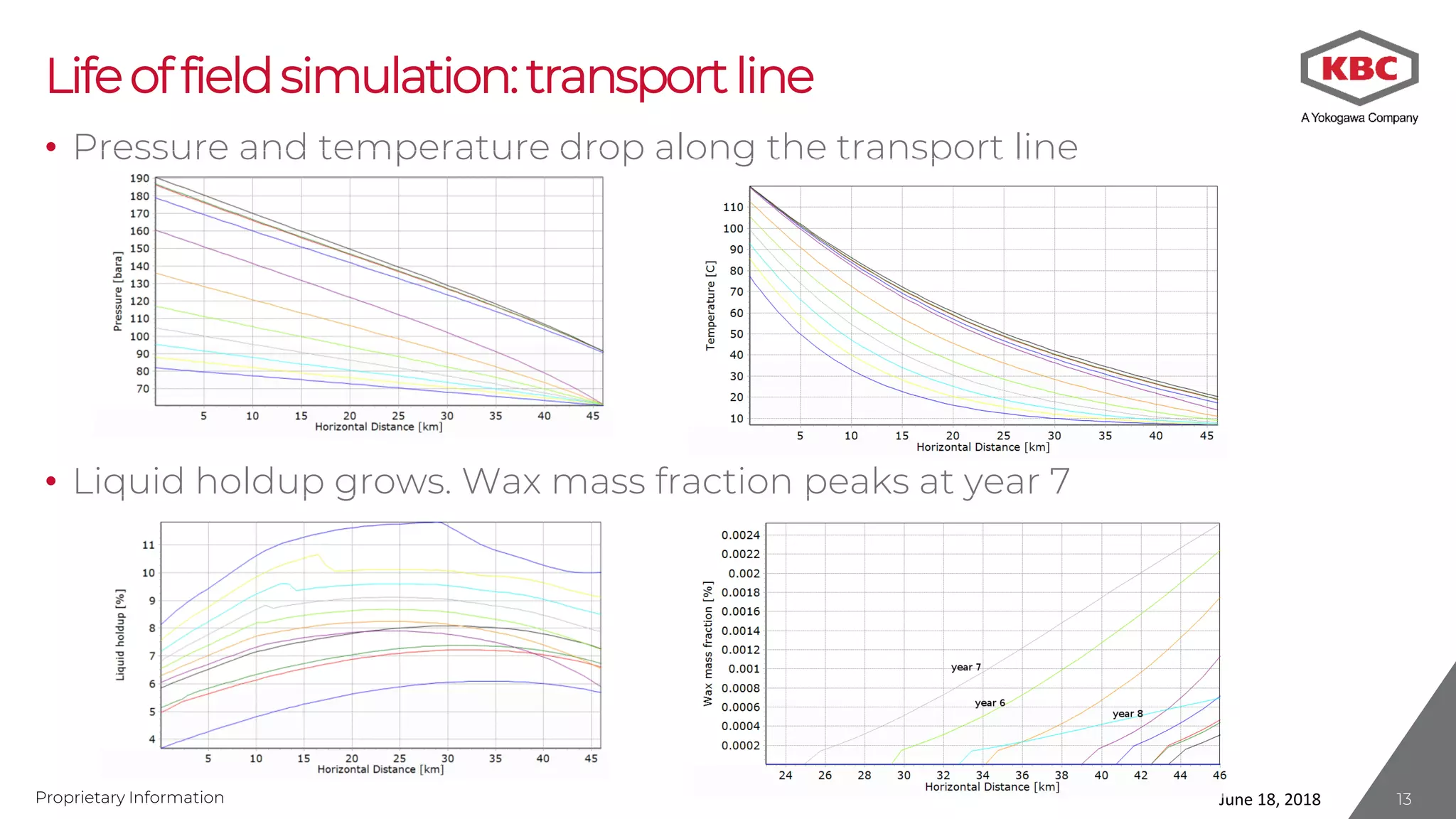

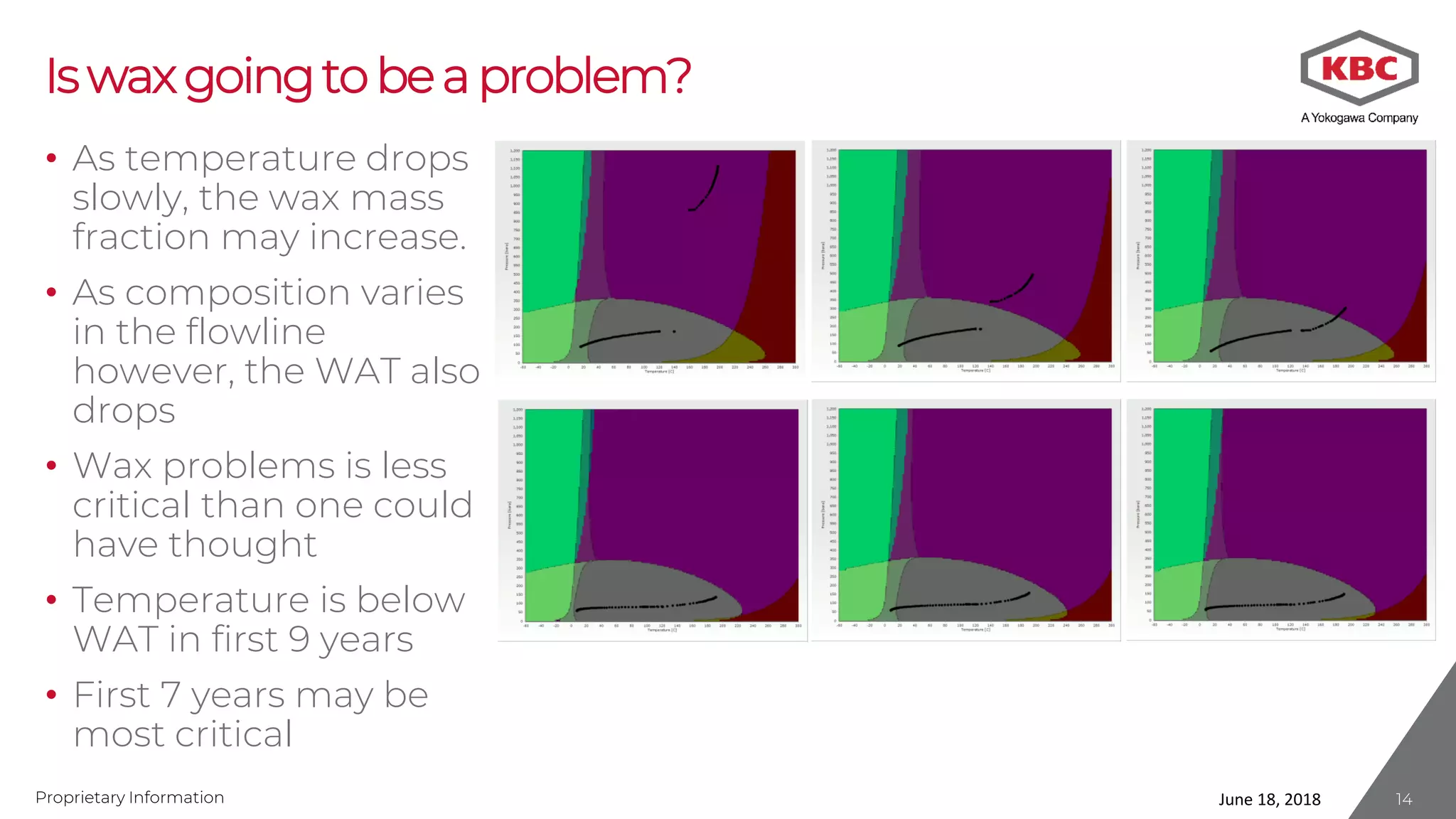

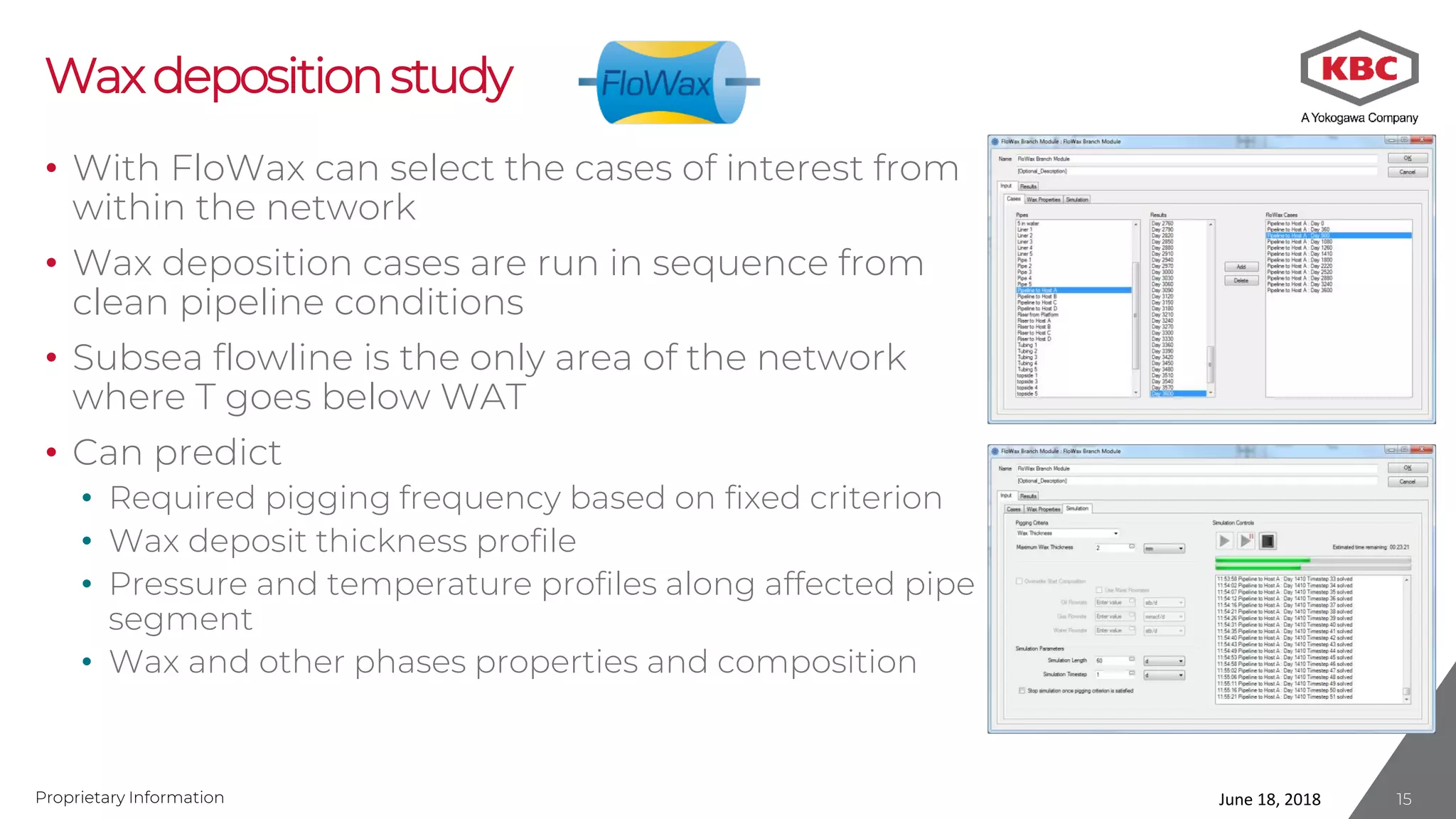

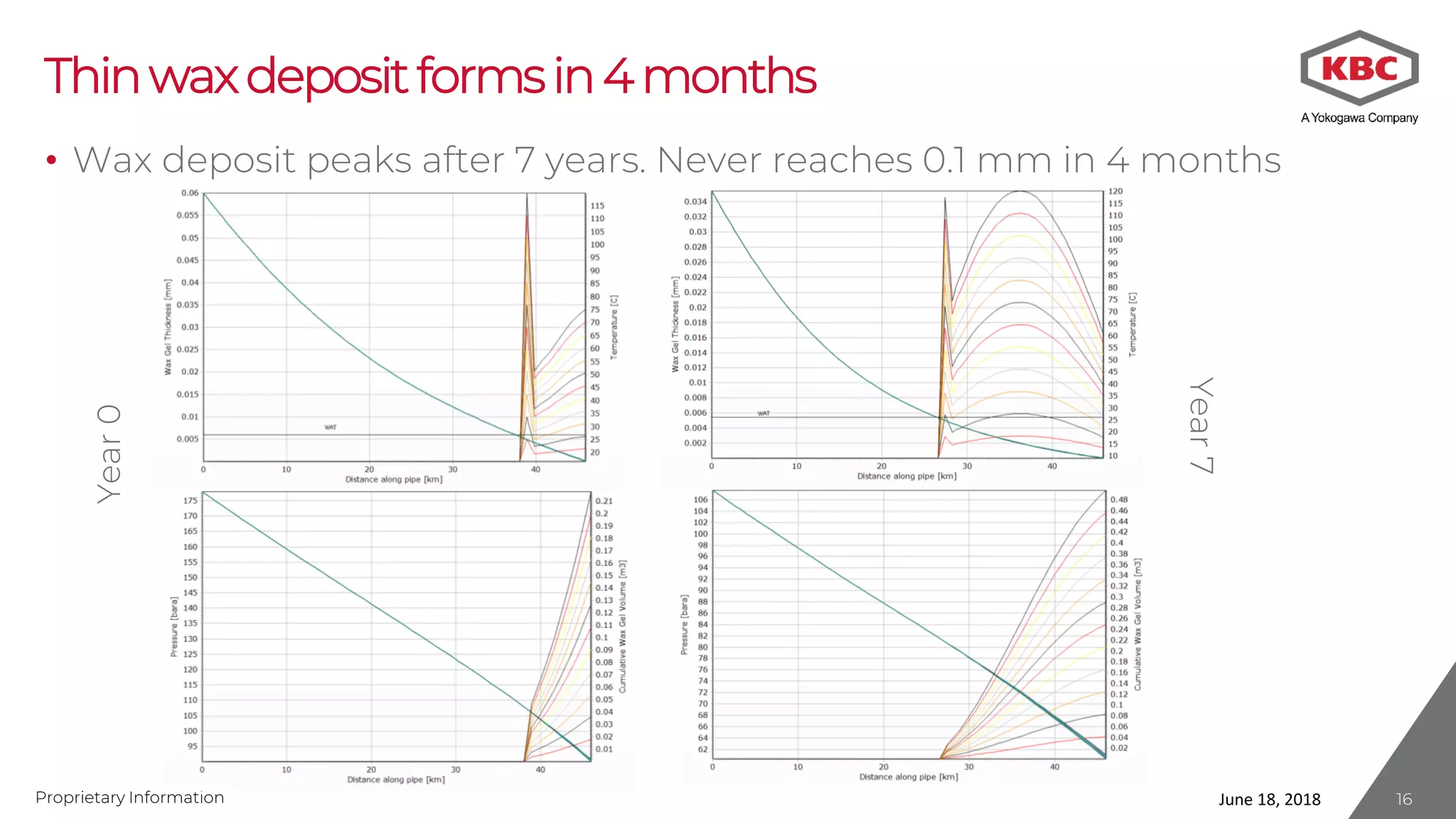

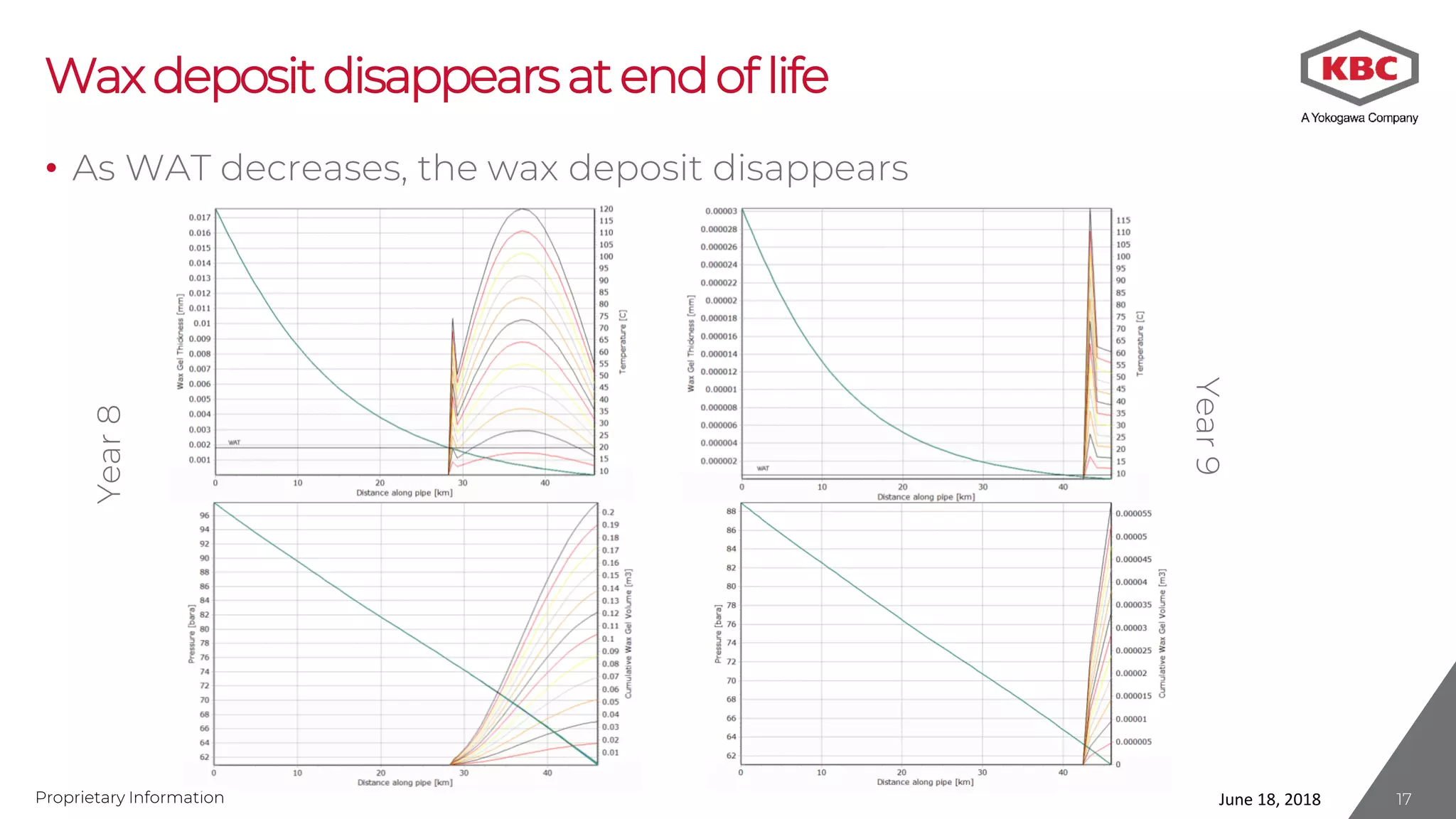

This document discusses wax deposition in oil and gas pipelines and presents the results of a wax deposition study for a condensate gathering system. It begins by explaining what wax is and how it deposits before discussing strategies for mitigating wax problems. It then describes a case study of a waxy condensate gathering plant where modeling was used to simulate wax deposition over the life of the field. The modeling showed that wax deposition would likely be a problem in the early years as pressure and temperature dropped but that the risk decreased over time as the wax appearance temperature also dropped. The study concluded that integrated modeling is useful for identifying real risks from wax deposition and determining the best strategy for mitigation or avoidance.