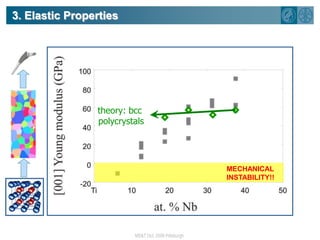

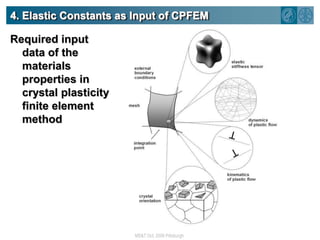

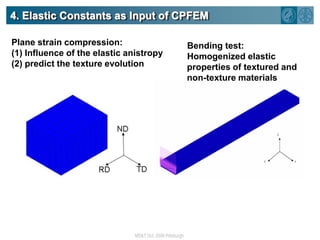

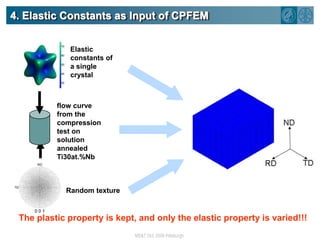

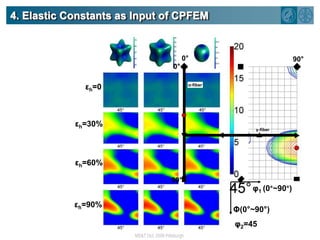

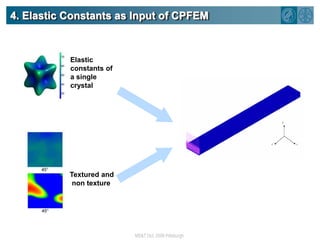

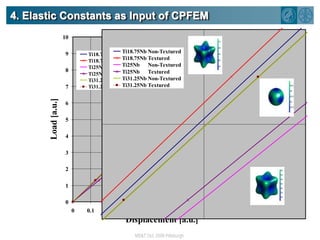

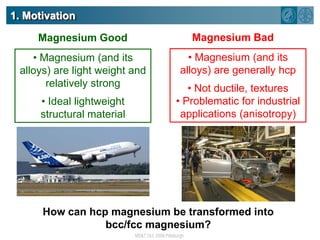

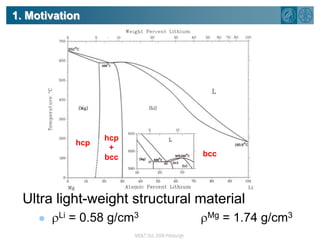

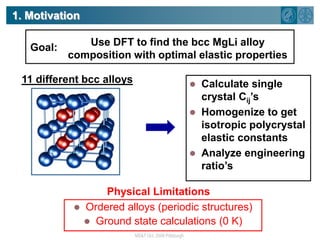

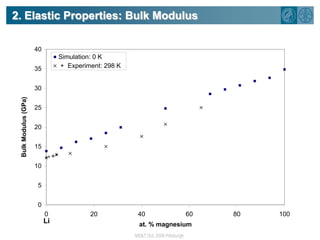

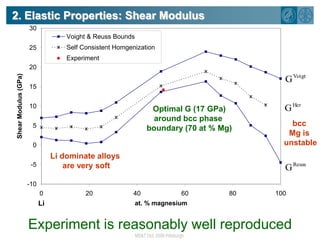

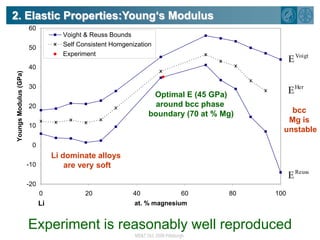

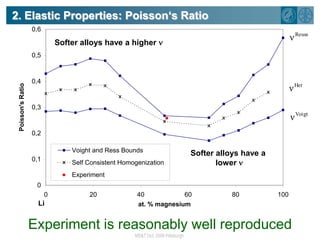

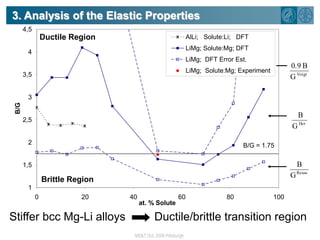

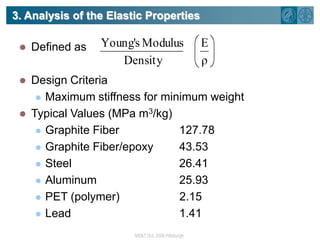

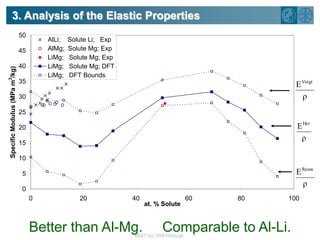

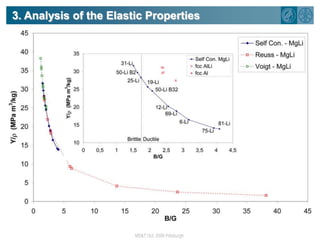

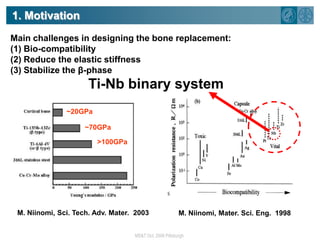

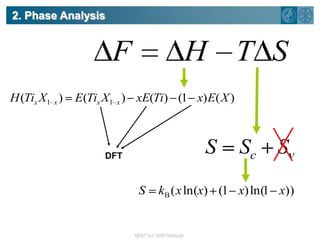

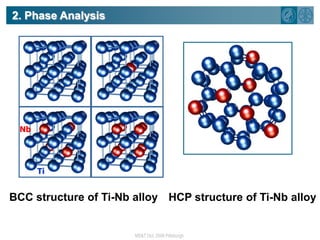

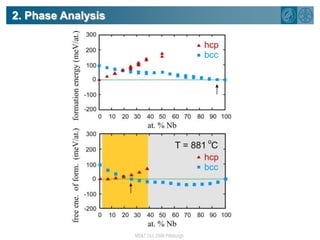

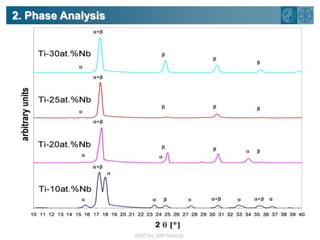

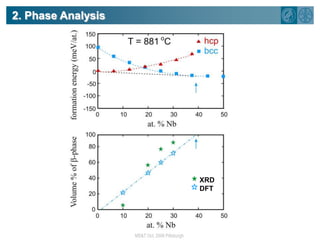

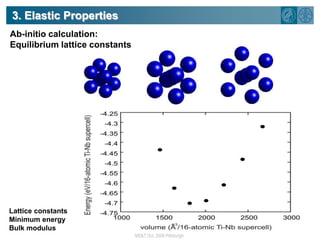

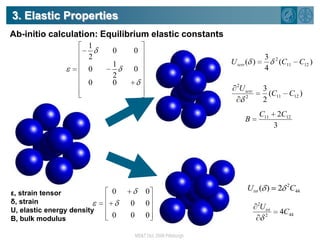

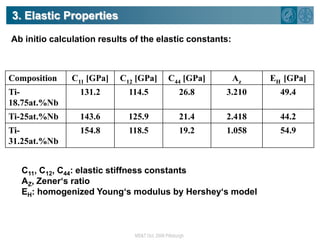

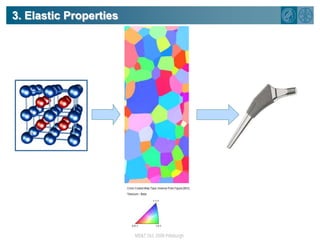

The document summarizes research on using density functional theory (DFT) coupled with continuum mechanics to design new alloys. It presents two examples: designing β-titanium alloys for implants by stabilizing the softer β-phase using niobium additions, and designing magnesium-lithium alloys for lightweight structures by stabilizing the bcc crystal structure. For the titanium alloys, DFT is used to analyze phases, calculate elastic properties, and determine that niobium additions stabilize the β-phase and make the alloys softer and more compatible for implants. For the magnesium alloys, DFT calculates the elastic properties of bcc magnesium-lithium alloys to identify compositions with optimal stiffness,

![3. Elastic PropertiesYoung‘s modulus surface plotsPure NbTi-25at.%NbTi-31.25at.%NbTi-18.75at.%Nb[001][100][010]Az=3.210Az=1.058Az=0.5027Az=2.418 The elastic properties of the Ti-Nb binary alloys become isotropic as the Nb content increases](https://image.slidesharecdn.com/dierk-raabe-ab-initio-simulations-in-metallurgy-1292142573-phpapp02/85/Dierk-Raabe-Ab-Initio-Simulations-In-Metallurgy-19-320.jpg)

![single-crystallineC11, C12, C44, B0micro-scalemacro-scalepolycrystallineYoung modulus3. Elastic Properties64μ H4 + 16(4C11 + 5C12)μ H3 + [3(C11+ 2C12) × (5C11+ 4C12) -8(7C11 – 4C12)C44]μ H2-(29C11 – 20C12)(C11+2C12)C44 μ H–3(C11 + 2C12)2(C11 – C12)C44 = 0 “scale-jumping”(across the meso-scale)](https://image.slidesharecdn.com/dierk-raabe-ab-initio-simulations-in-metallurgy-1292142573-phpapp02/85/Dierk-Raabe-Ab-Initio-Simulations-In-Metallurgy-21-320.jpg)