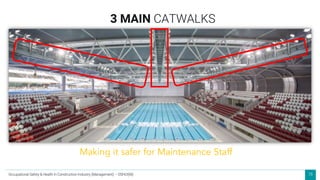

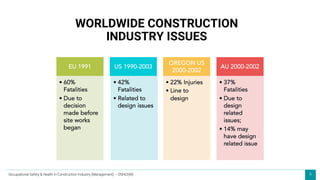

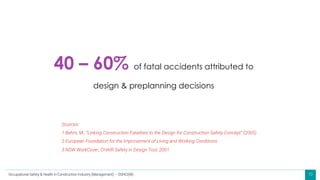

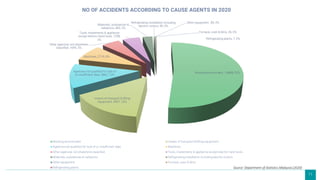

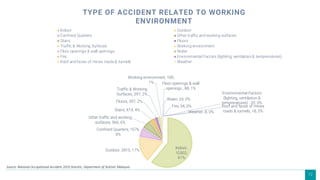

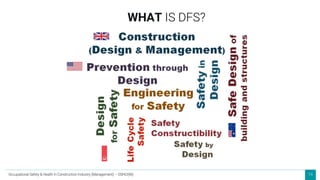

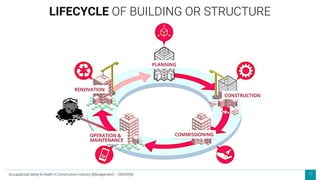

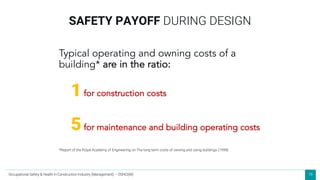

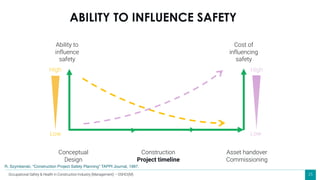

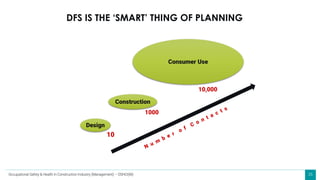

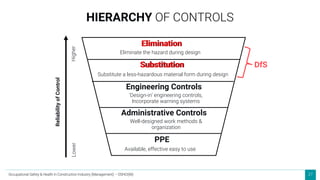

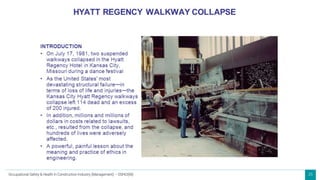

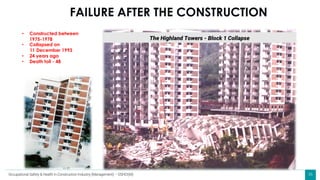

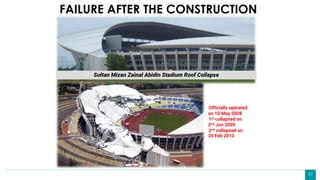

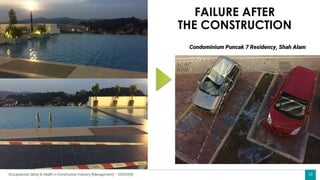

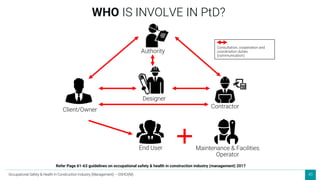

The document provides an introduction to Design for Safety (DfS) concepts in construction management. It discusses how 40-60% of construction accidents are attributed to design and pre-planning decisions. DfS aims to explicitly consider construction and maintenance safety during the design phase in order to reduce accidents. Implementing DfS principles such as hazard elimination and substitution can help lower safety costs over the lifetime of a building. The document also gives examples of construction failures in Malaysia that occurred after projects were completed.

![ABOUT

DR. LINA

PhD in Construction, Engineering & Infrastructure Management [2013-2017]

DR. MAZLINA ZAIRA MOHAMMAD

? YEARS YOUNG

DIPLOMA IN CIVIL ENGINEERING [2008]

BACHELOR IN CIVIL ENGINEERING [2011]

MBA [2012]

ERASMUS+MOBILITY [2016]

SAFETY & HEALTH OFFICER [2018]

SENIOR LECTURER [2018 – CURRENT]

CONSTRUCTION BUSINESS & PROJECT MANAGEMENT

CIVIL ENGINEERING

SAFETY EXECUTIVE TRAINEE [2018]

JOHOR PORT SAFETY DEPARTMENT

ENGINEER EXECUTIVE [2013]

SPECIAL PROJECT & TECHNOLOGY

TRAINEE ENGINEER [2010]

WATER TREATMENT PLANT](https://image.slidesharecdn.com/dfsslide2022-230714074314-e0f51fda/85/DfS-SLIDE-pdf-3-320.jpg)

![6

WORKPLACE FATAL ACCIDENTS BY SECTOR

MALAYSIA STATISTIC [Until Dec 2019]

Sources: Department of Occupational Safety and Health (DOSH) Malaysia,

October 2017

84

Construction

2019

WORKPLACE

FATAL

ACCIDENTS

259

OSH STATISTIC

16

Business service

& Retail Trades

21

Logistic

&

Transport

17

Others

73

Manufacturing

48

Agriculture

& Mining

Occupational Safety & Health in Construction Industry (Management) – OSHCI(M)](https://image.slidesharecdn.com/dfsslide2022-230714074314-e0f51fda/85/DfS-SLIDE-pdf-6-320.jpg)

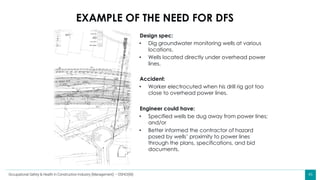

![47

EXAMPLE OF THE NEED FOR DFS

[ELIMINATION & SUBSTITUTION]

Occupational Safety & Health in Construction Industry (Management) – OSHCI(M)](https://image.slidesharecdn.com/dfsslide2022-230714074314-e0f51fda/85/DfS-SLIDE-pdf-47-320.jpg)