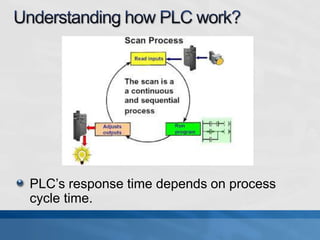

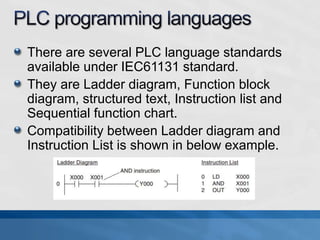

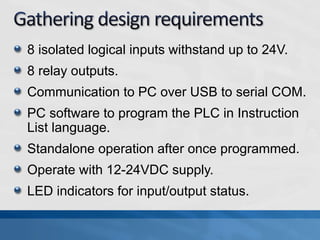

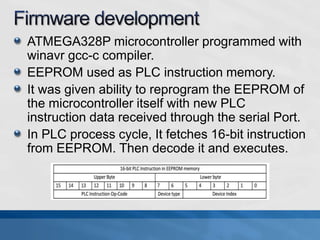

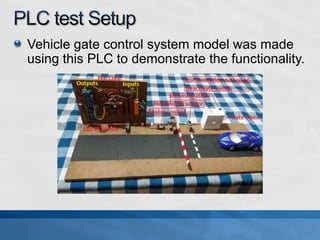

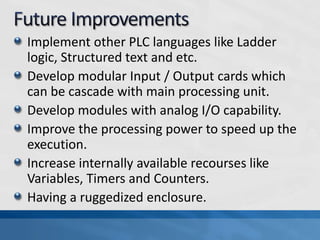

This document describes the development of a low-cost programmable logic controller (PLC) as an educational project. An Arduino Nano board is used as the microcontroller, which is programmed using C/C++ to emulate basic PLC functions. Inputs, outputs, timers and instructions are implemented to allow programming through a PC software interface. A vehicle gate control model demonstrates the functionality of the prototype PLC, which costs under 10% of commercial PLCs but has limitations such as fixed I/O and slower execution speed. Suggested future improvements include supporting additional PLC programming languages and modular/analog I/O expansion.