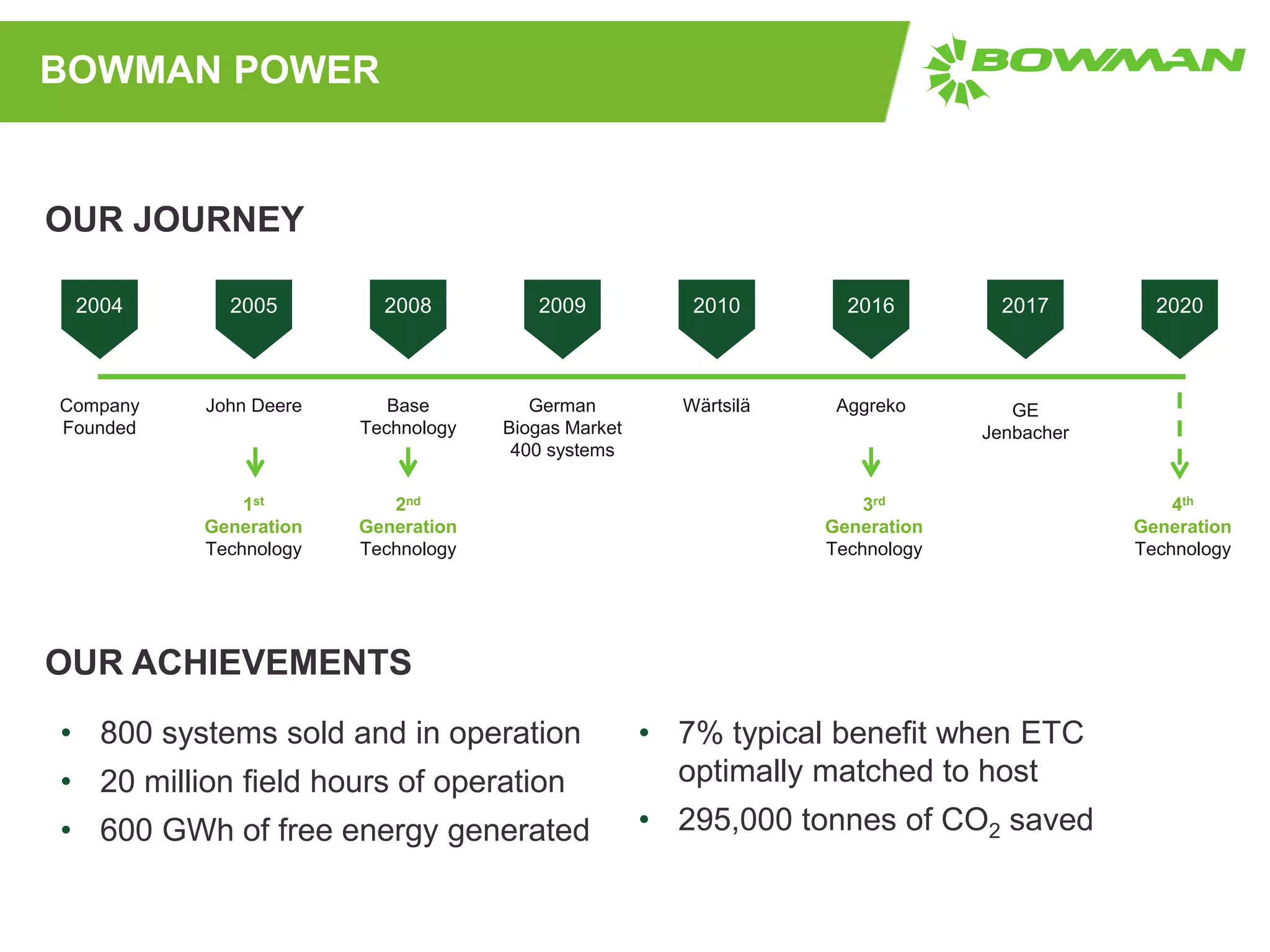

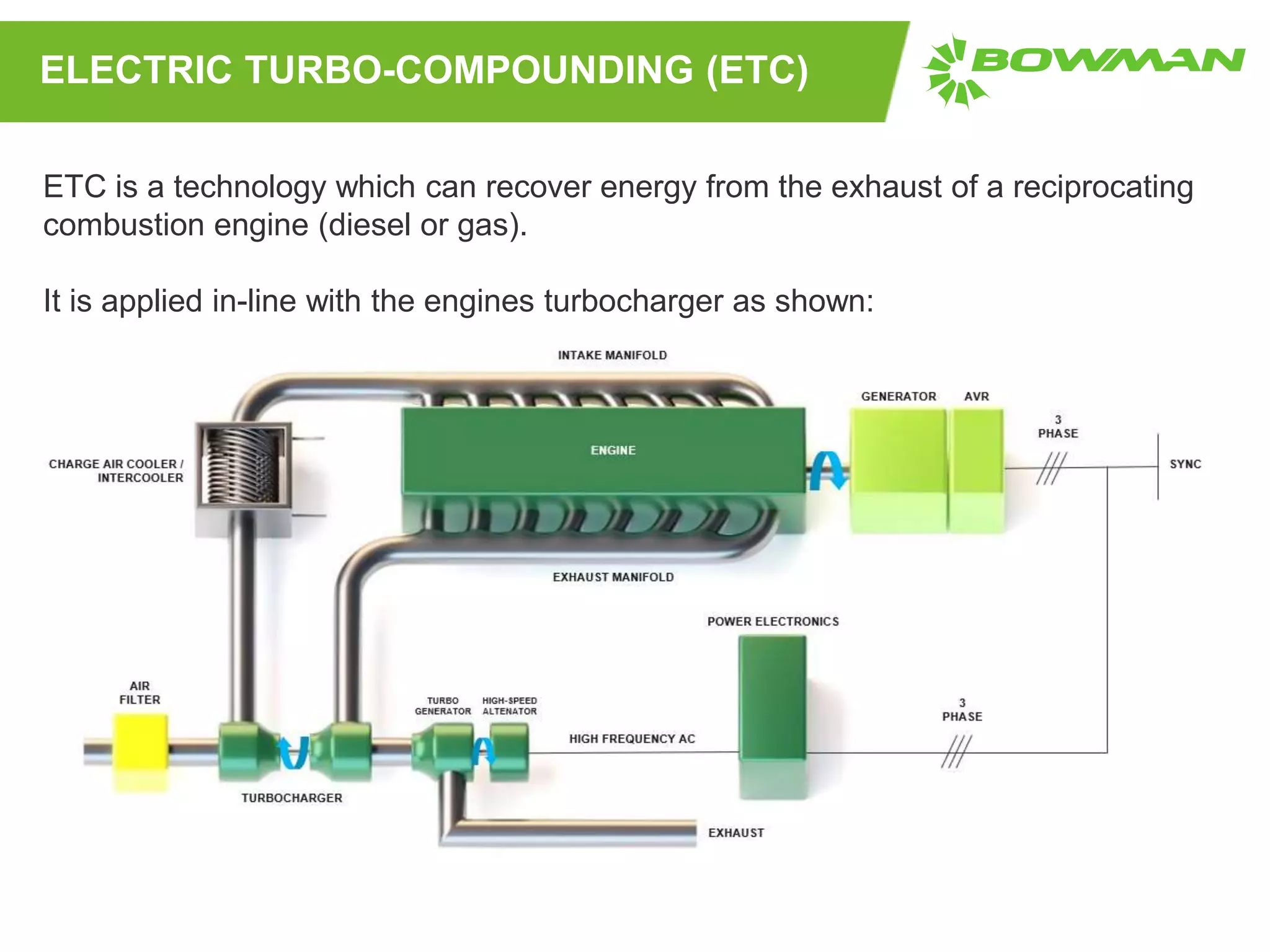

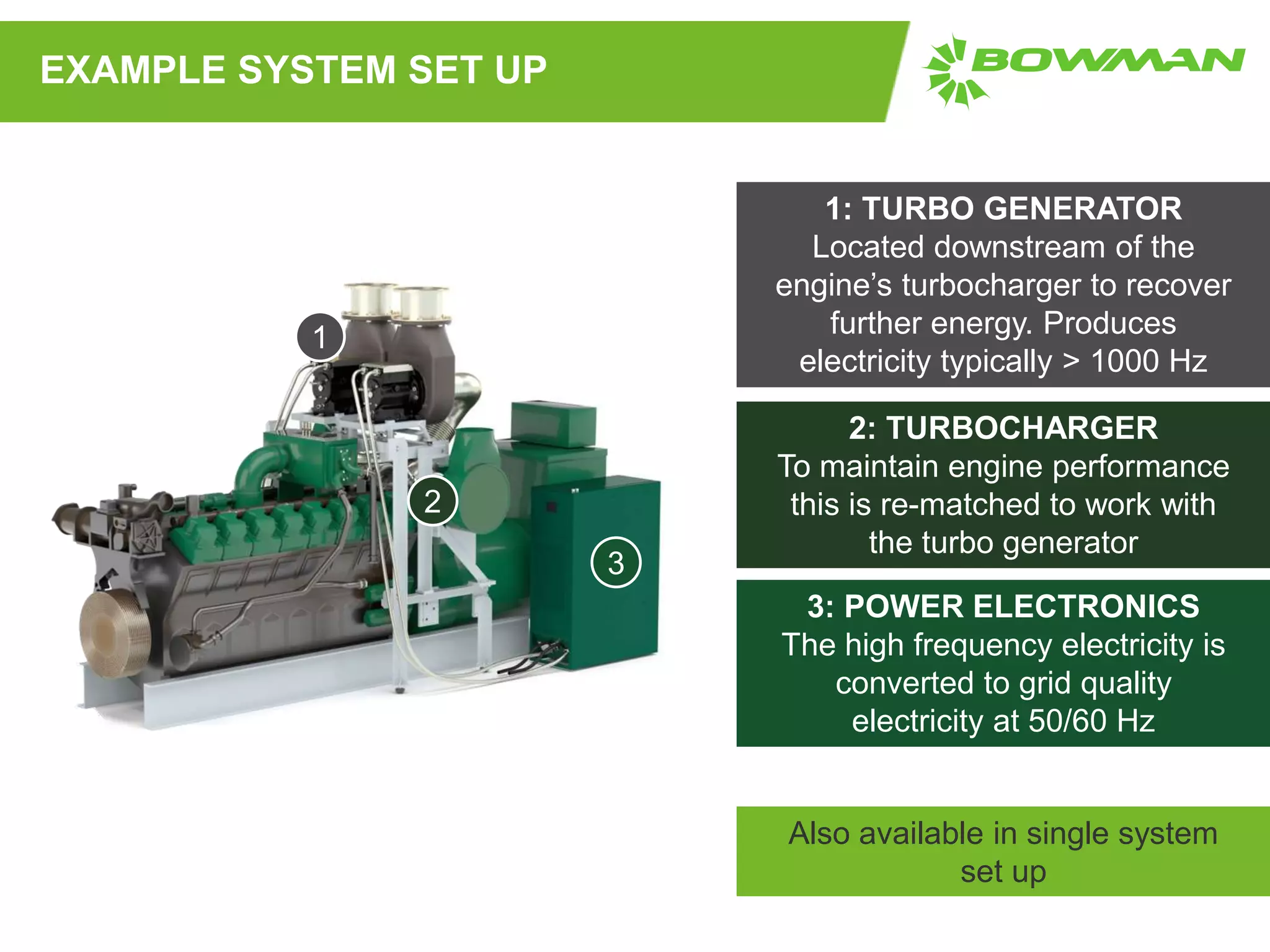

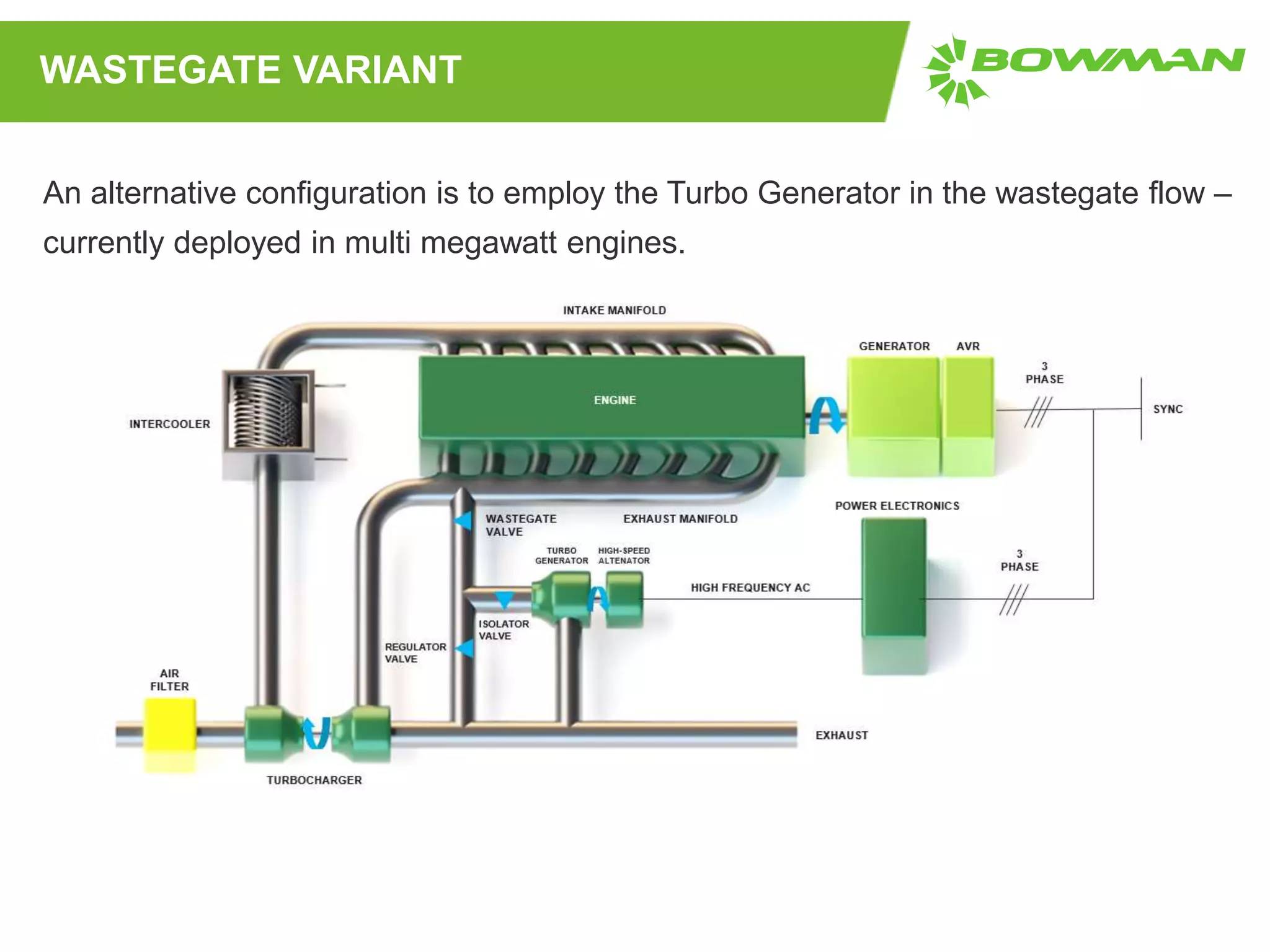

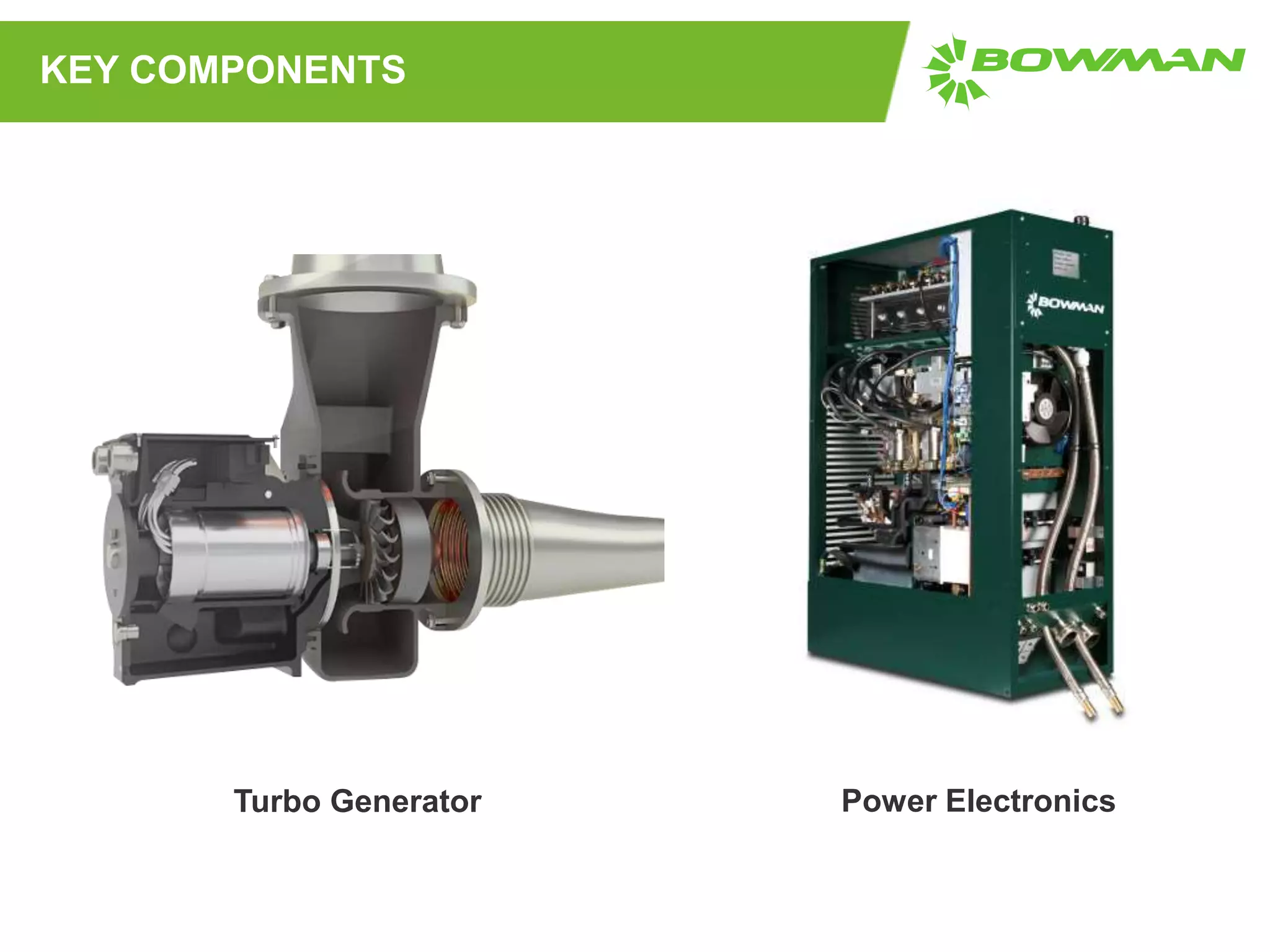

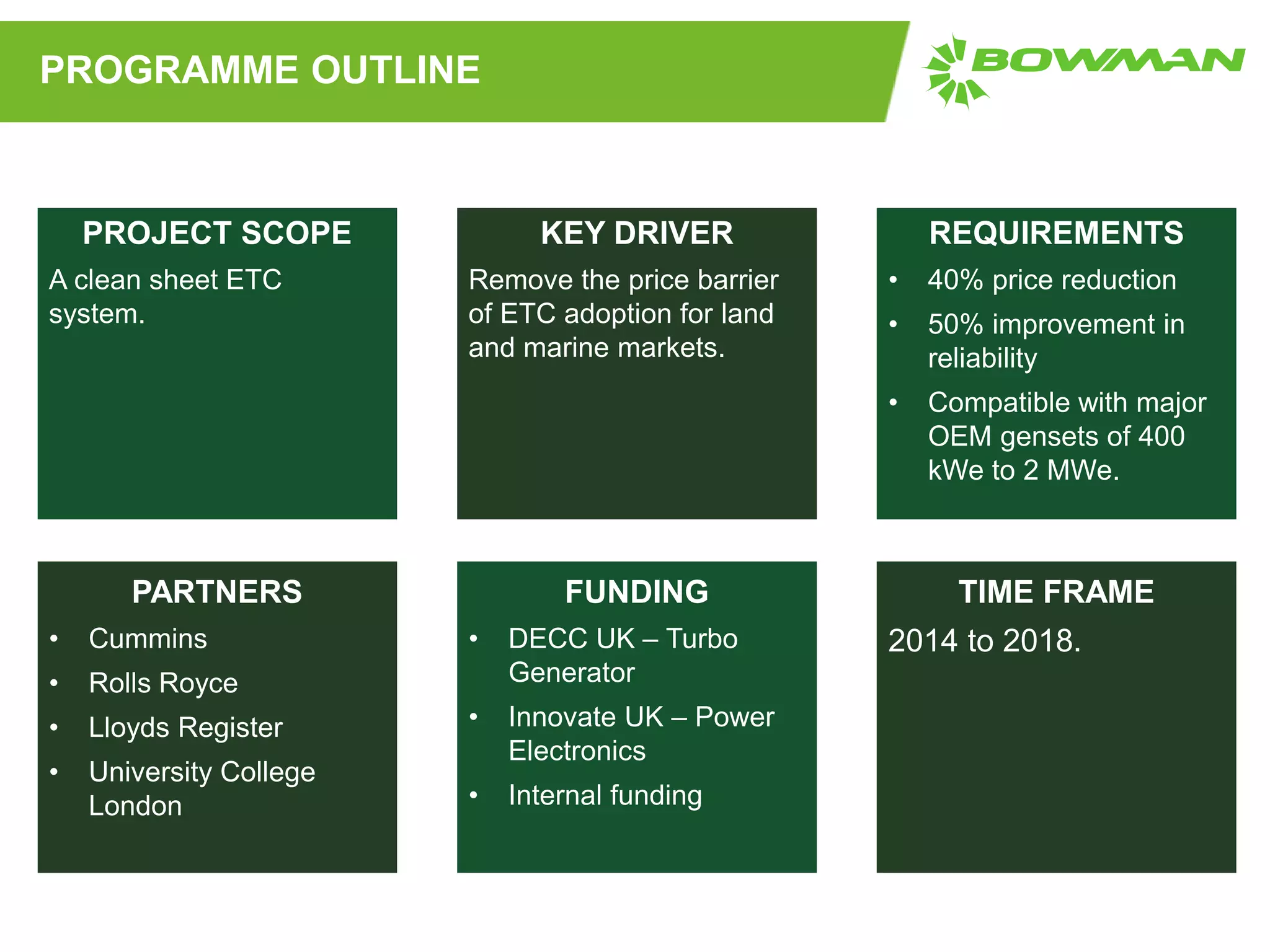

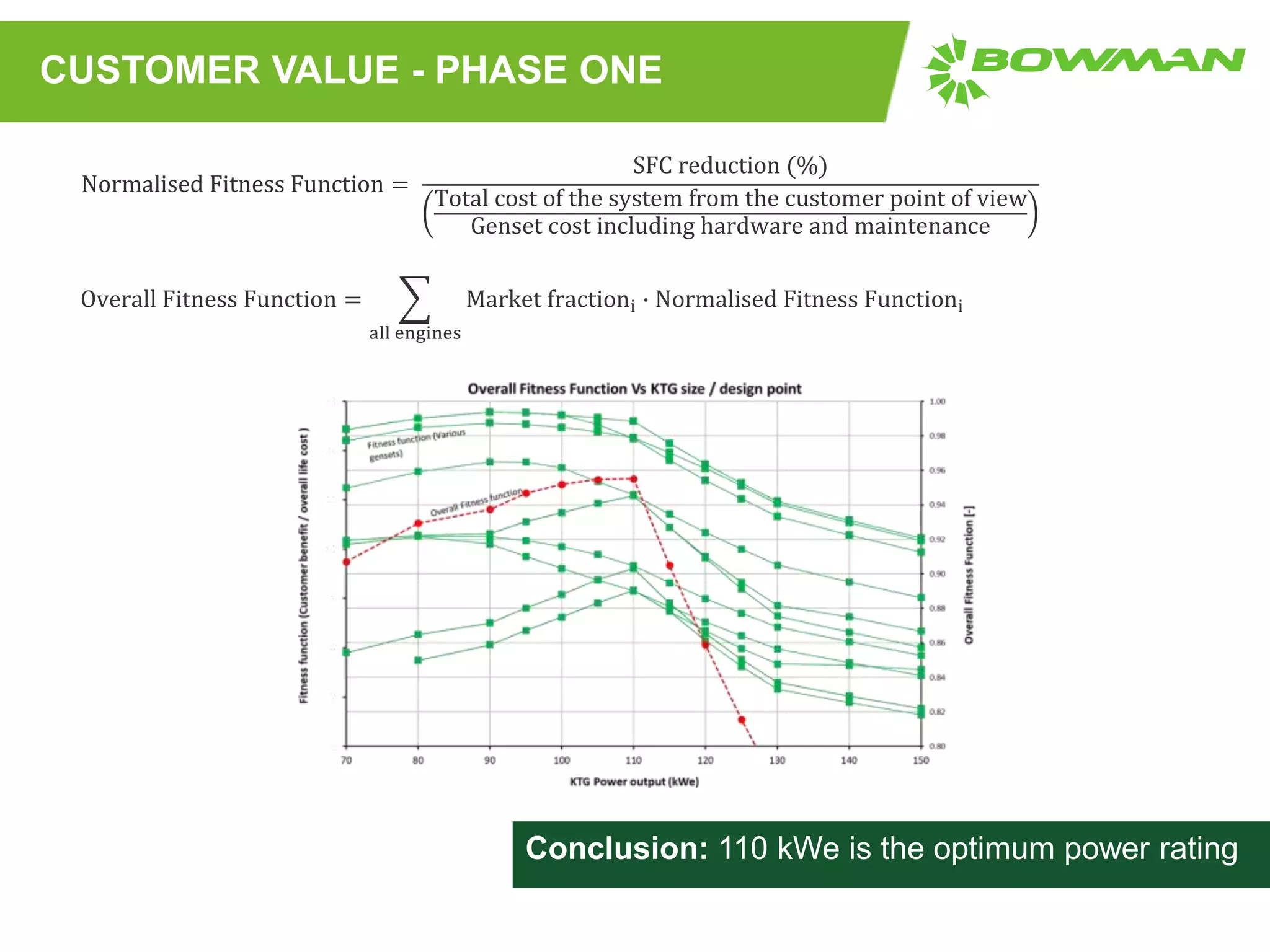

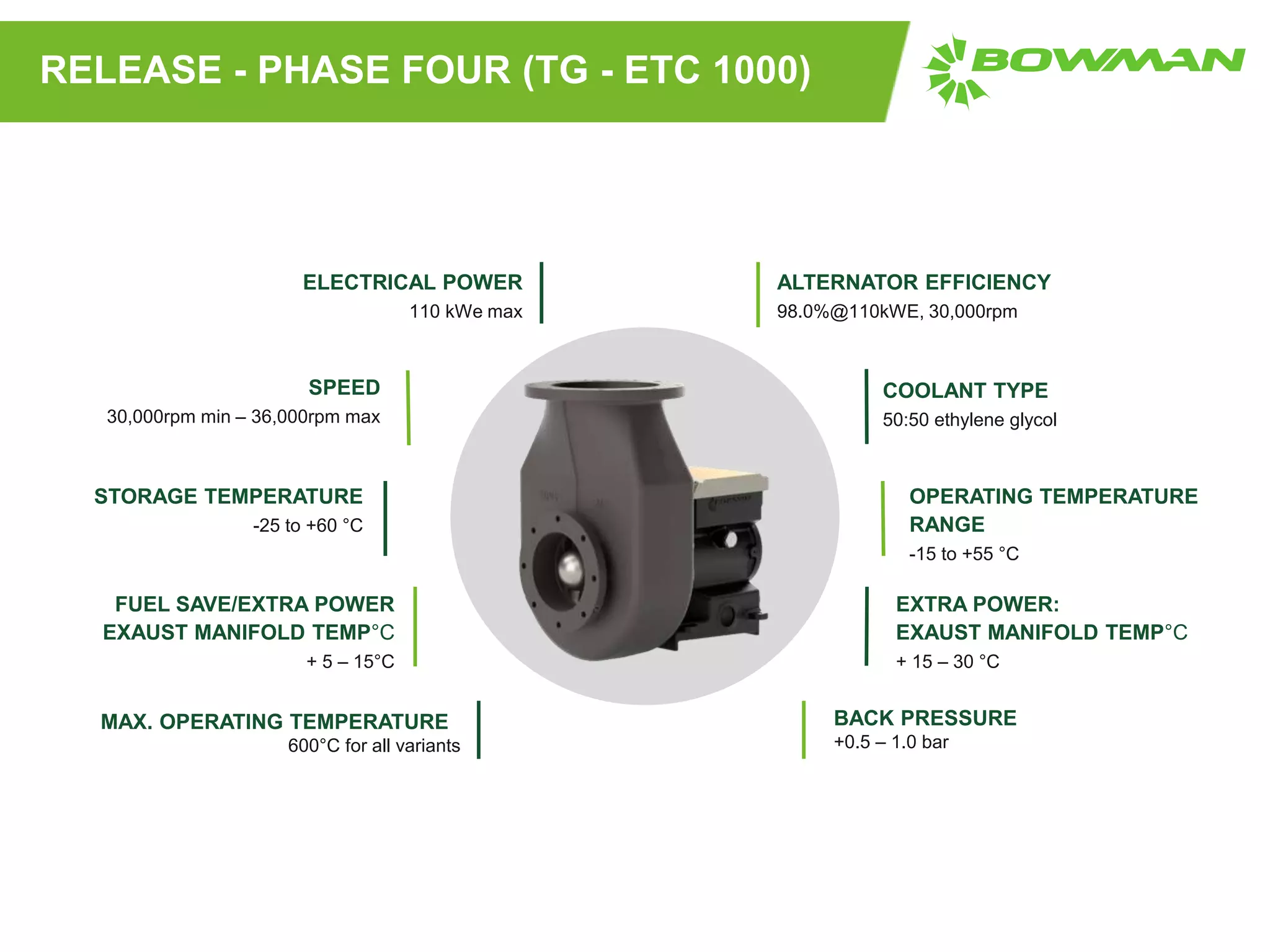

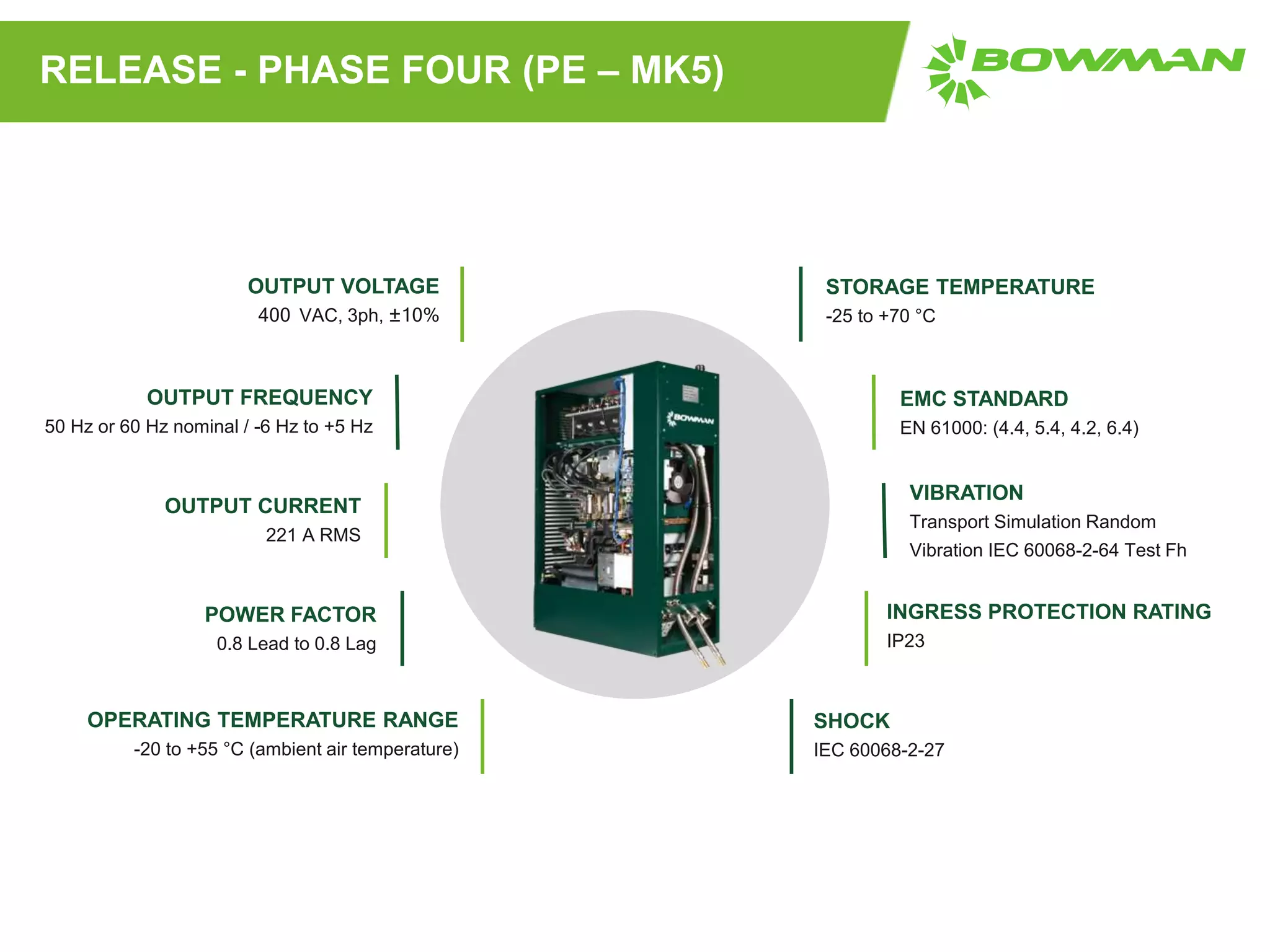

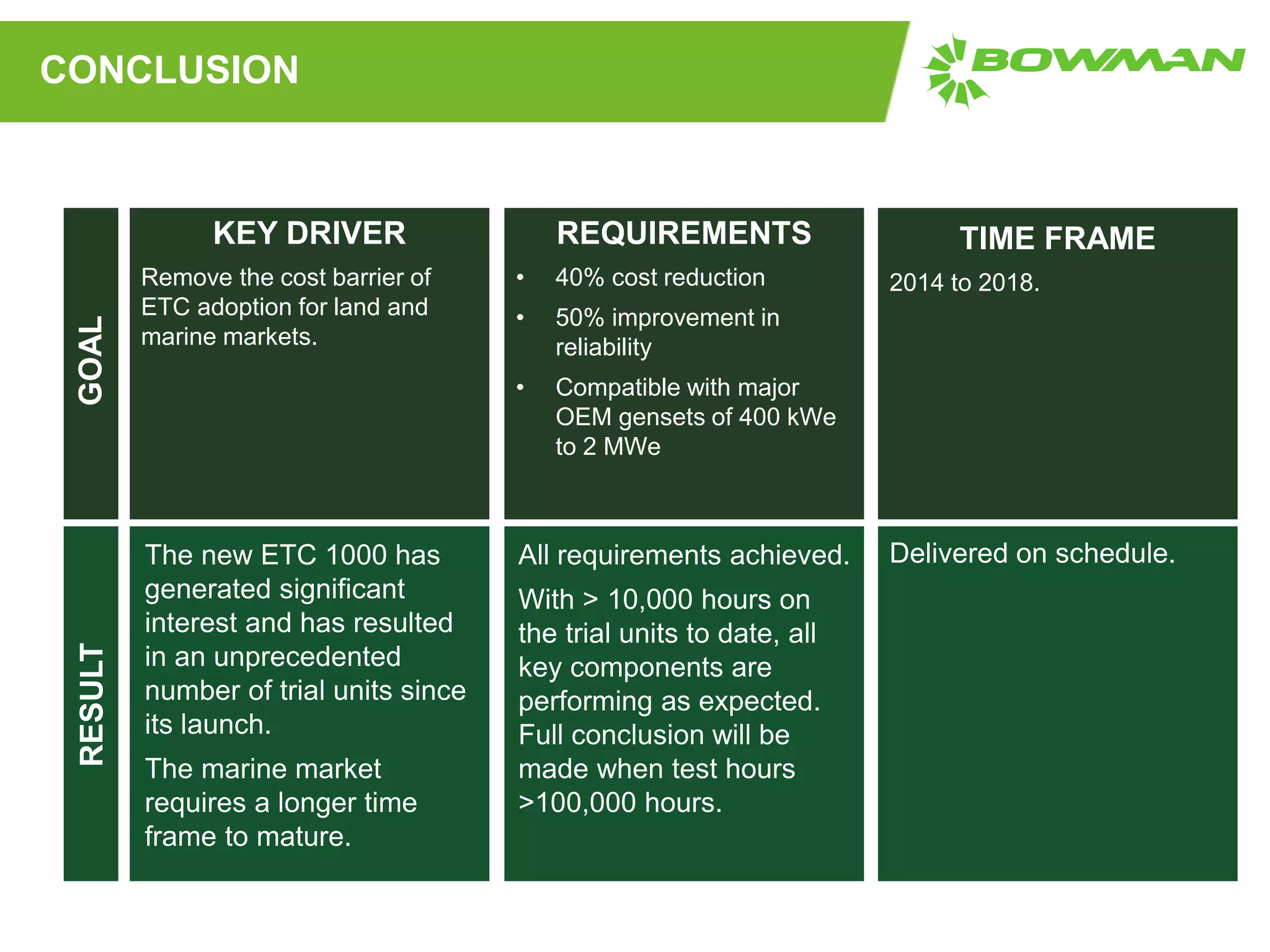

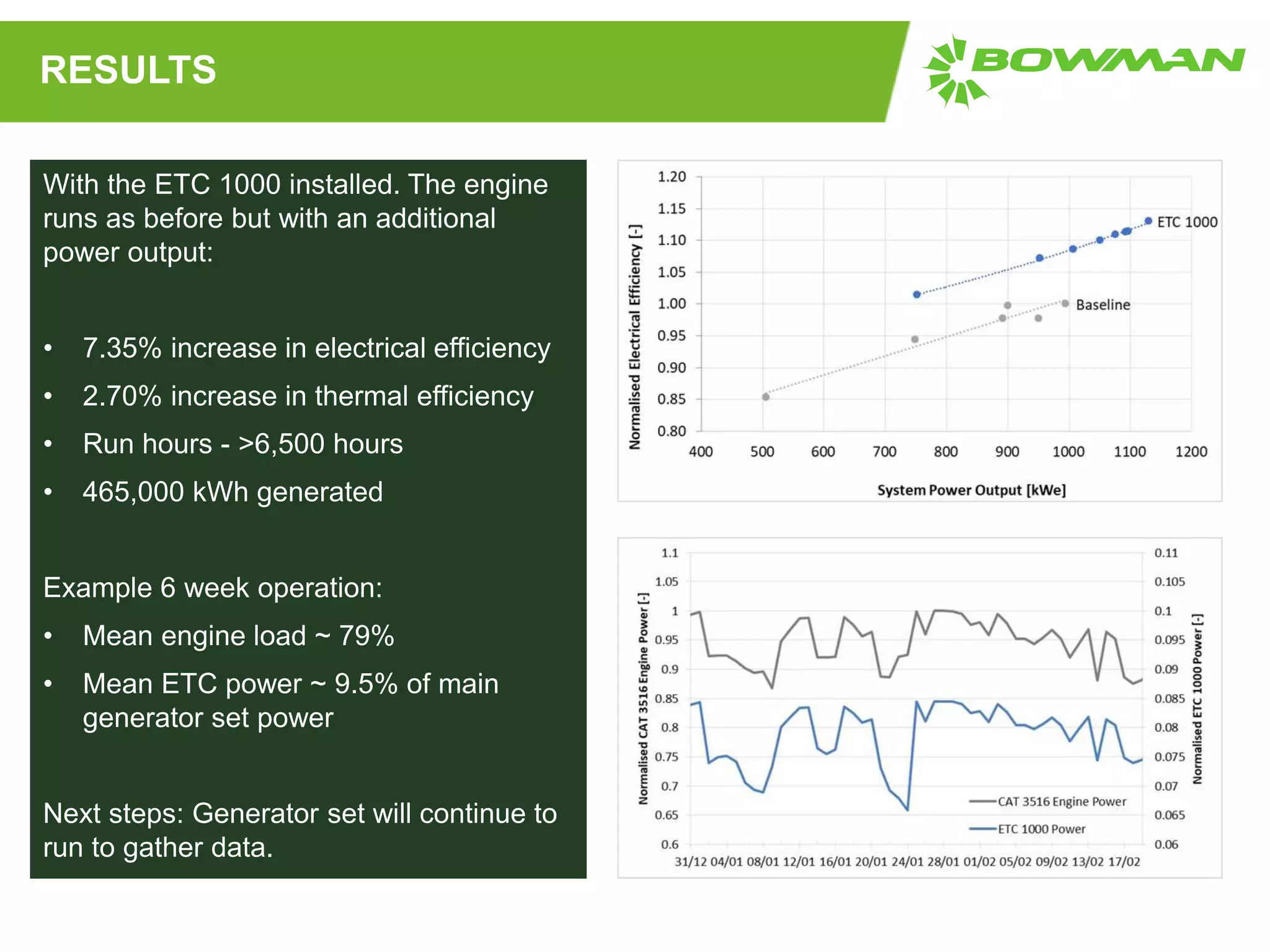

Bowman Power specializes in electric turbo compounding (etc) systems that convert waste exhaust energy into electrical power, enhancing engine efficiency. With a history of 14 years in development, the company has sold 800 systems, producing significant savings in CO2 emissions and energy generation. The latest etc 1000 technology boasts 40% reduced costs and improved reliability, now deployed in various power generation applications.