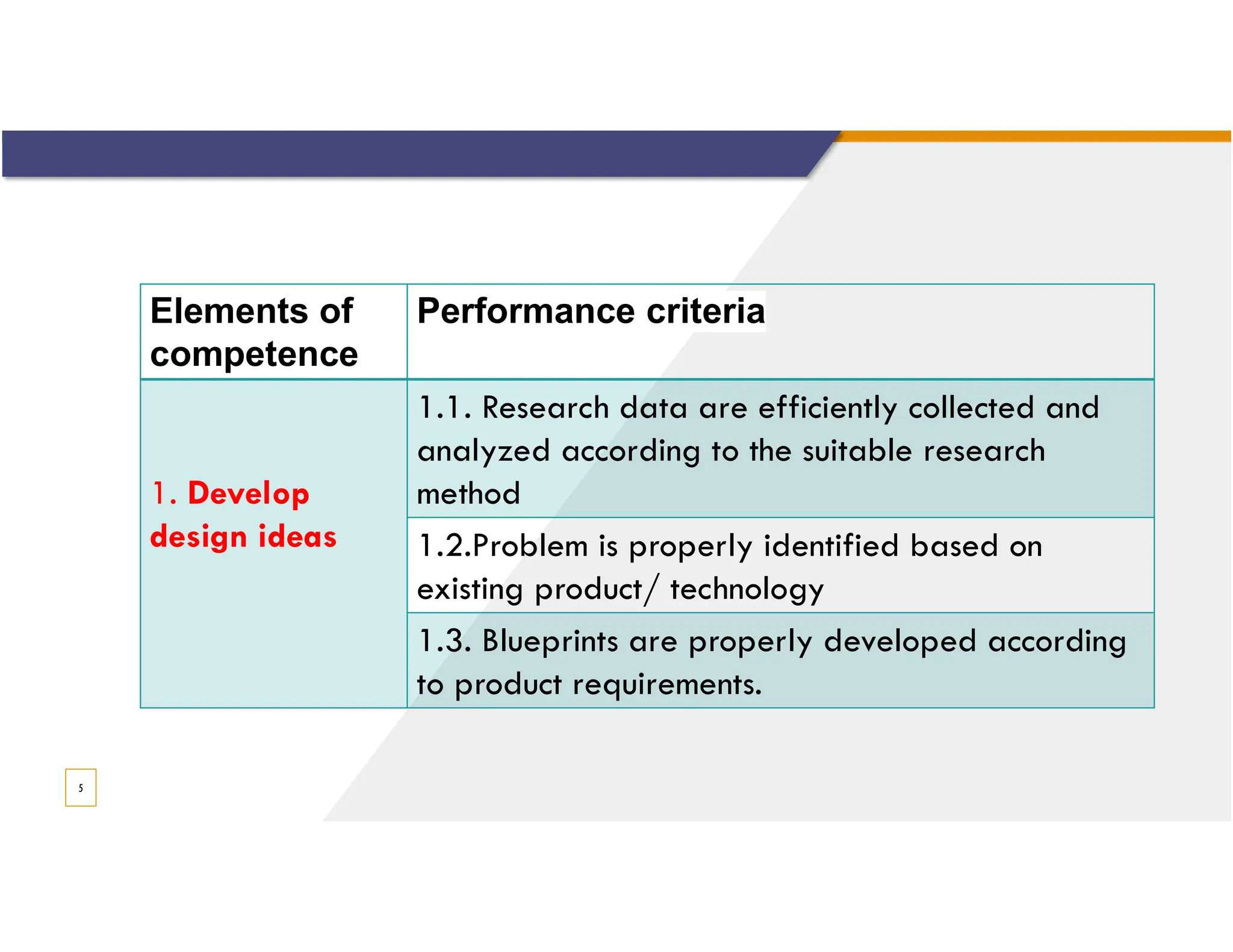

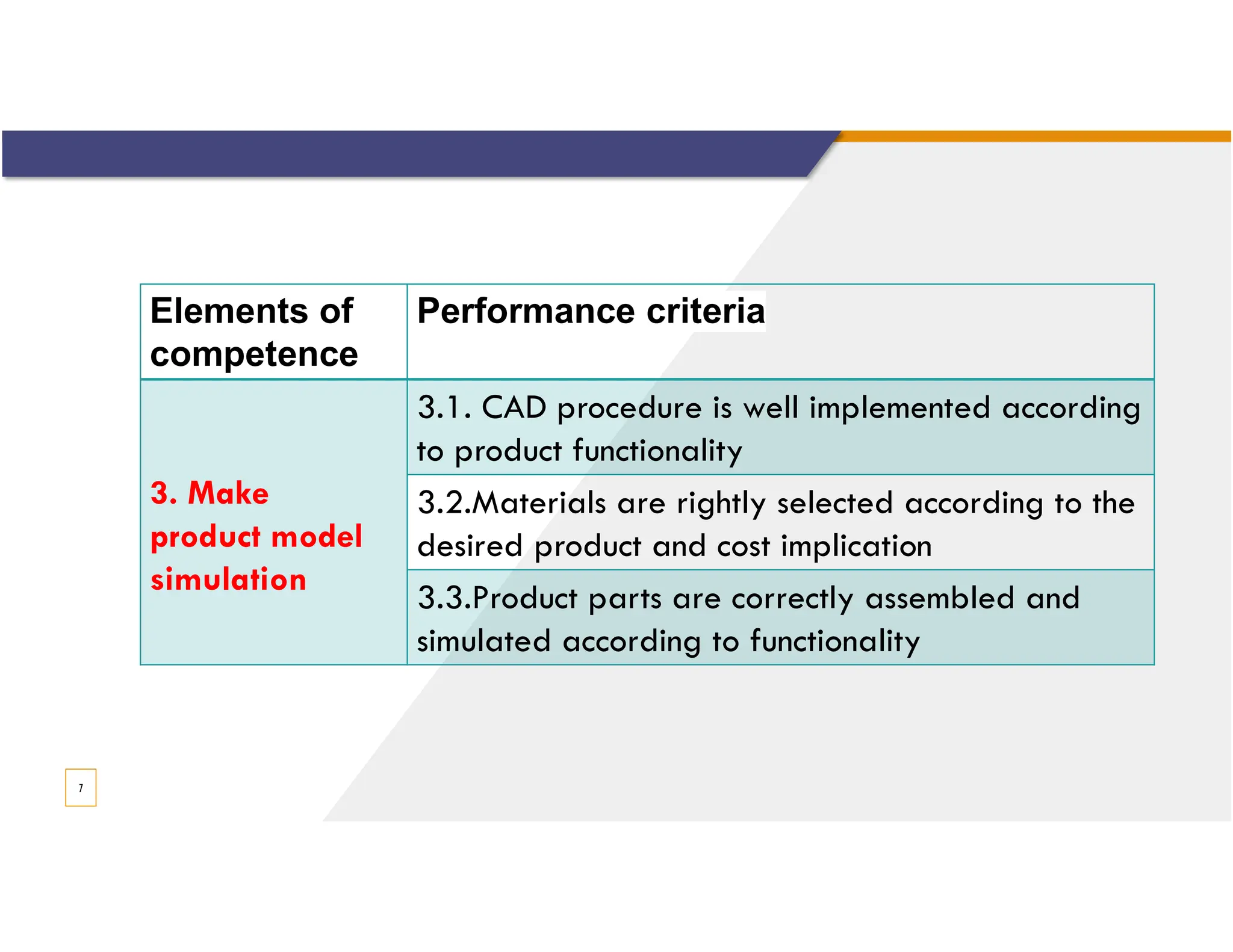

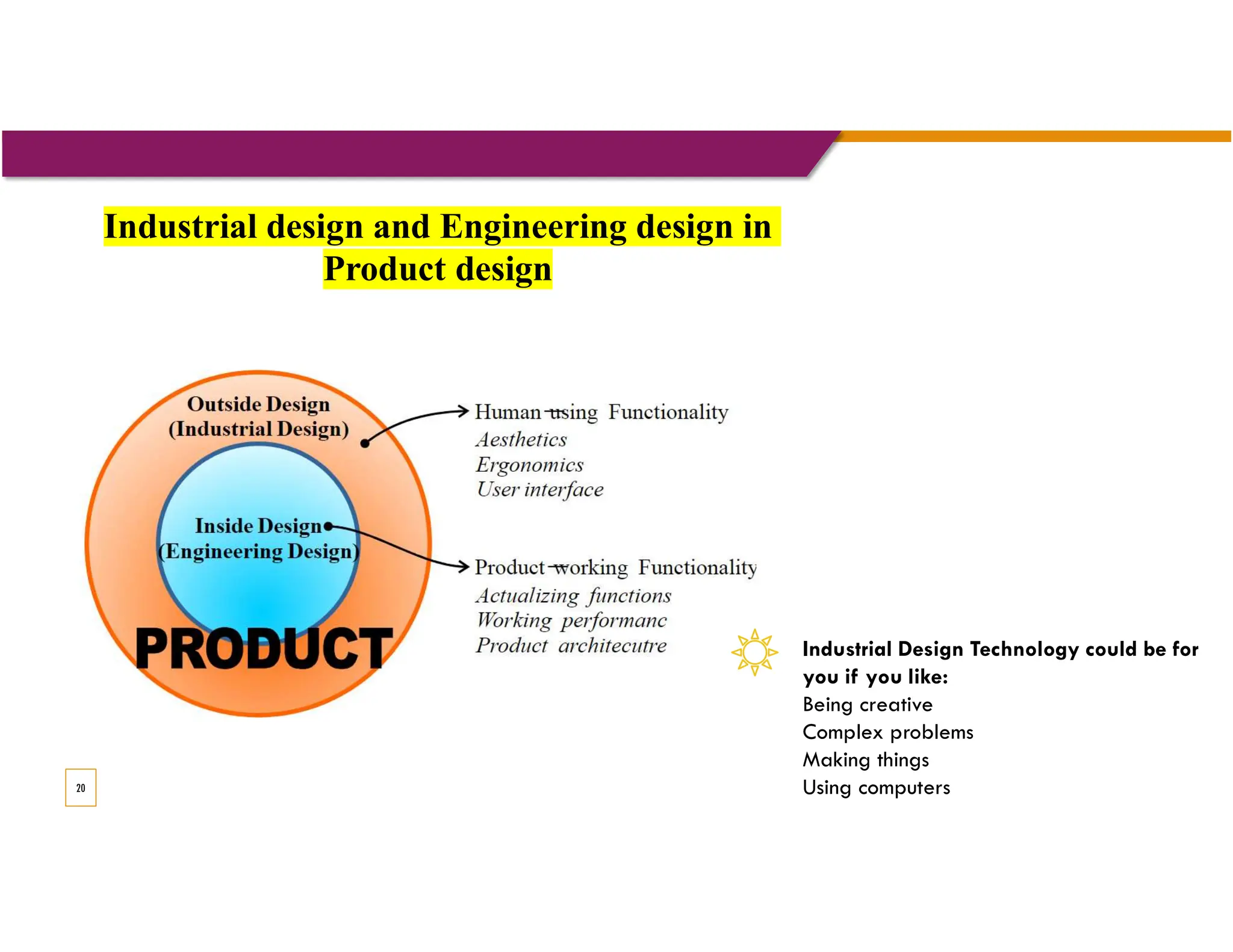

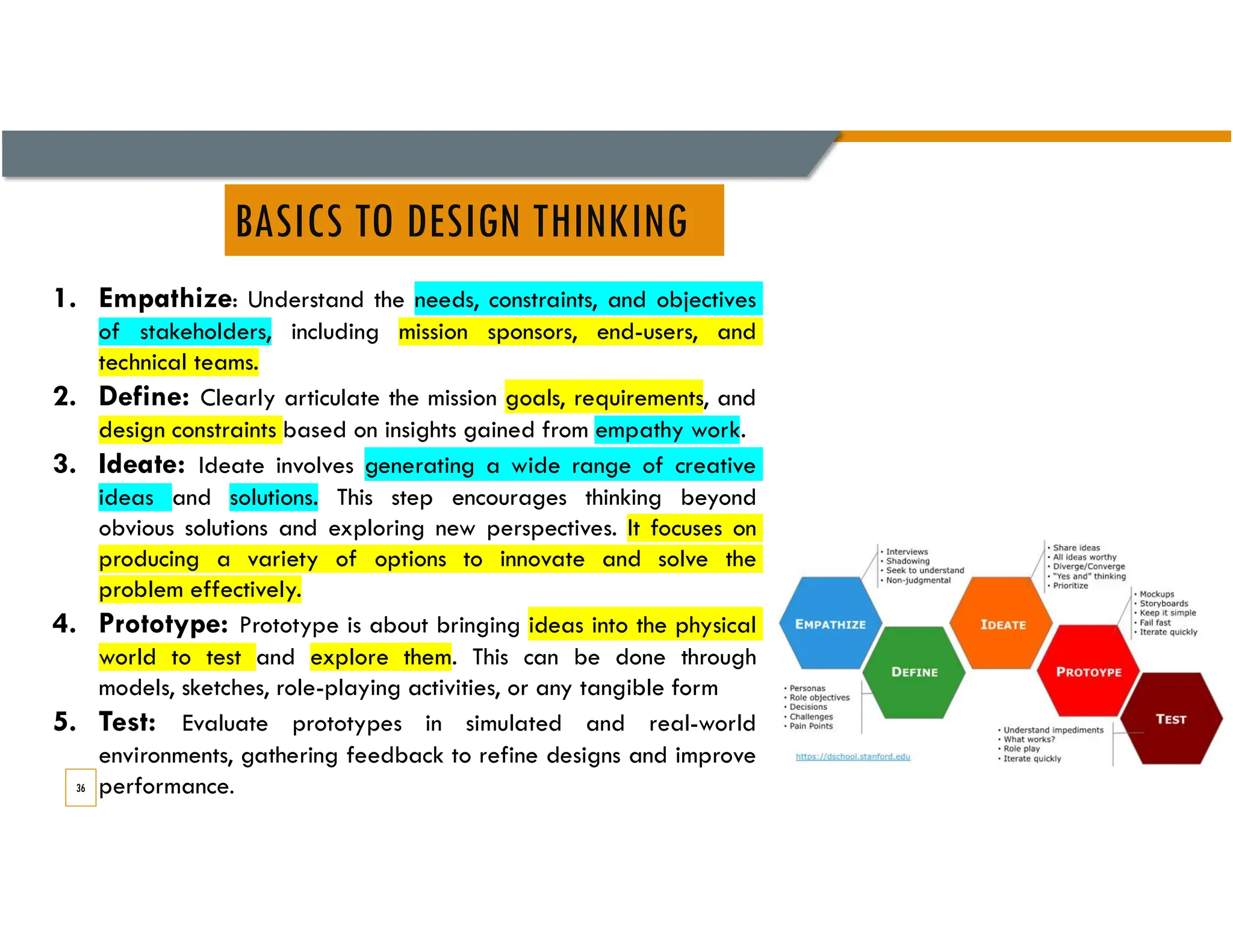

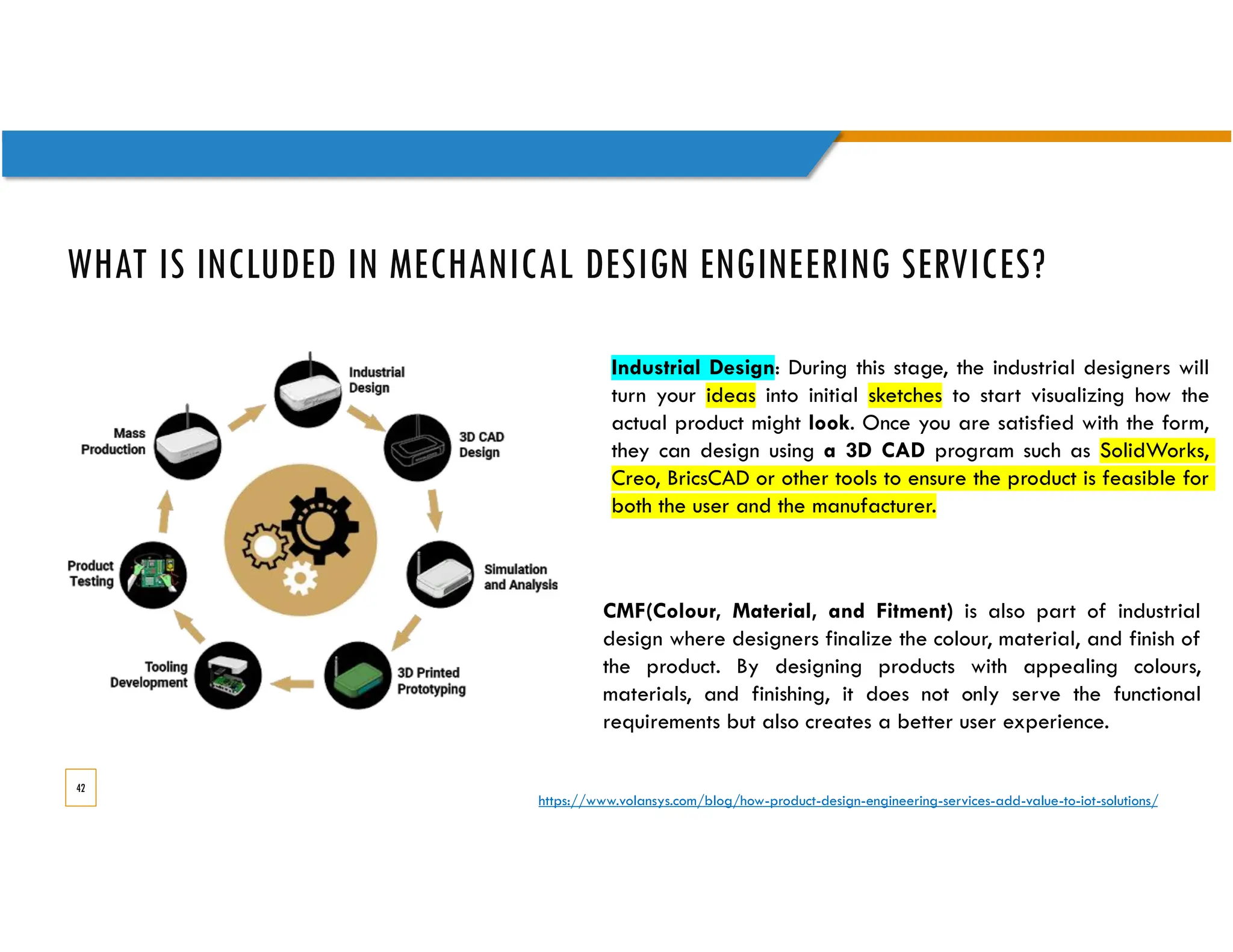

The document outlines the curriculum for the Bachelor of Technology in Manufacturing Technology at Rwanda Polytechnic, focusing on the Module MATID801: Industrial Design for Manufacturing Process. Key competencies include developing design ideas, generating design concepts, simulating product models, supervising prototype manufacturing, and developing industrial documentation. It emphasizes a systematic design approach, integrating creativity and problem-solving to achieve functional and aesthetically appealing products for the manufacturing industry.