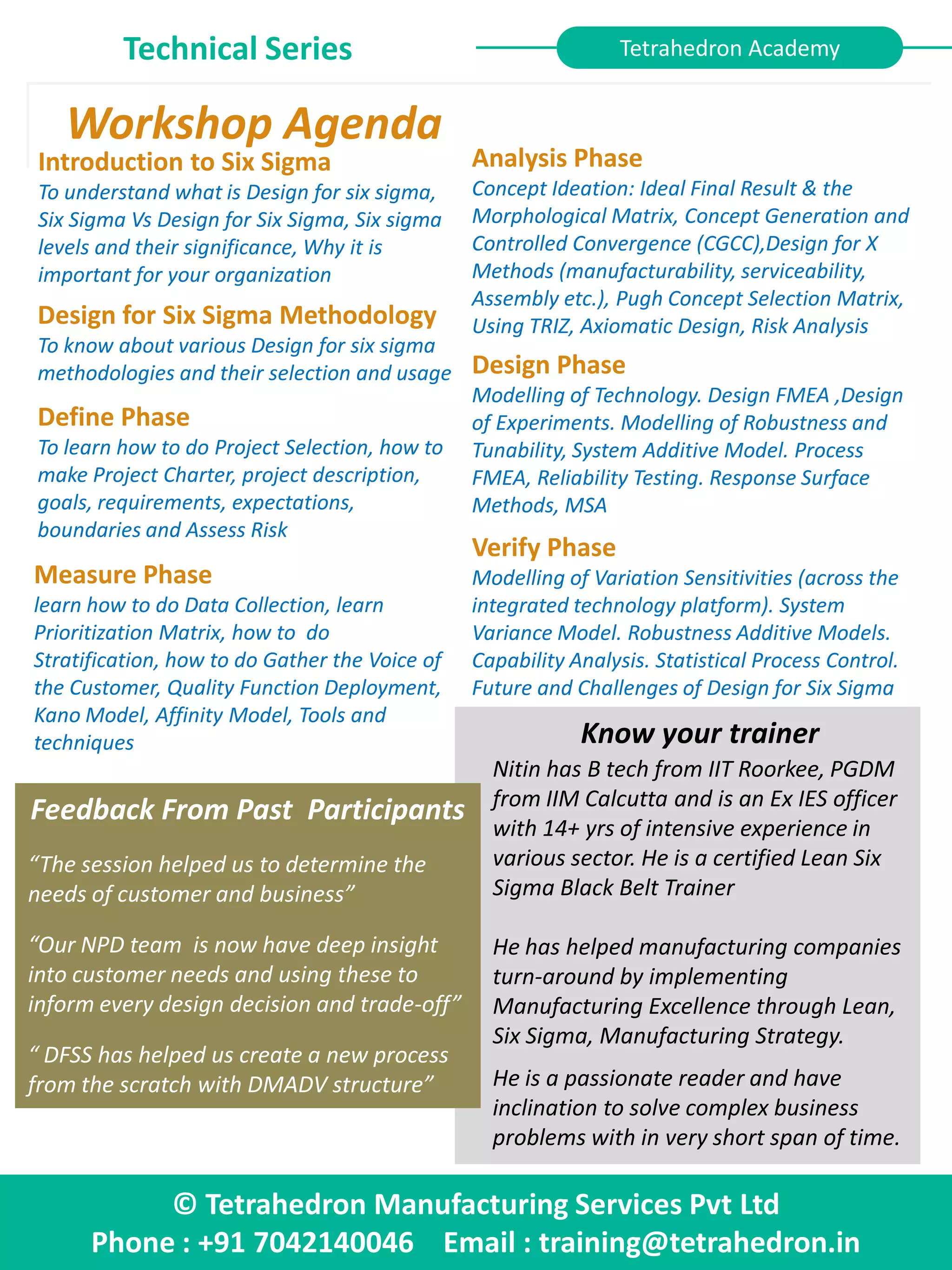

This document provides information on a 2-day Design for Six Sigma (DFSS) workshop. DFSS focuses on understanding customer and process needs to minimize redesign through critical parameter management. The workshop objectives are to design robust products and processes using DFSS methodology to meet Six Sigma performance levels and customer requirements. Benefits include reduced design complexity, improved quality, reduced time to market, and cost savings. The agenda covers DFSS phases and tools including define, measure, analysis, design, and verify.