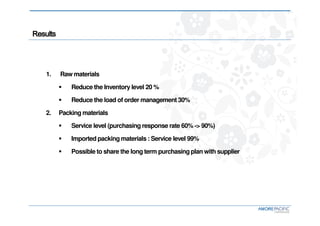

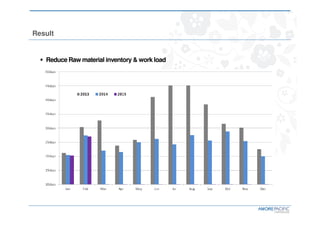

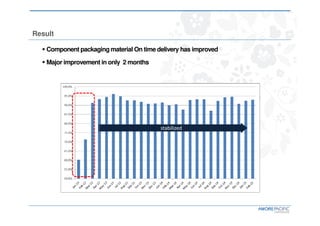

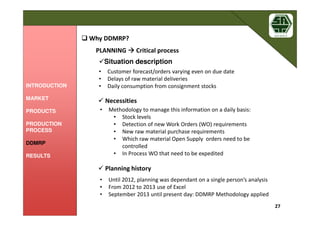

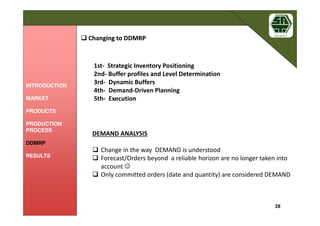

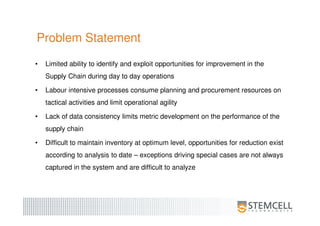

Demand Driven MRP Case Studies provides an overview of three successful DDMRP implementations at Amore Pacific, Satuerca, and StemCell. At Amore Pacific, DDMRP helped reduce raw material inventory by 20% and order management workload by 30%. Satuerca saw a 35% reduction in inventory levels and 50% reduction in lead times. StemCell adopted DDMRP to improve service levels while maintaining optimal inventory levels and establish efficient planning processes.

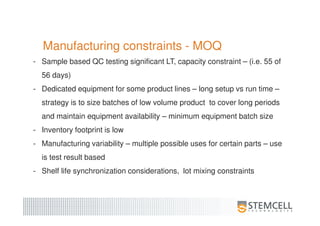

![Good forecasting?

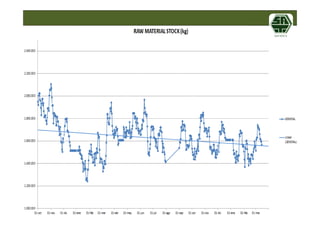

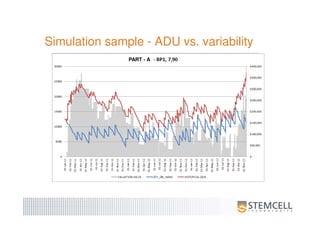

• Sales Forecast : The accuracy of M+3 forecast is less than 10%.

Purchasing team could not depend on the sales forecast,

used only as a reference.

• Best policy of purchasing department : Try to reduce the lead time

because the accuracy of short term forecast is high.

[ Accuracy of Sales Forecast]](https://image.slidesharecdn.com/erikbushpowerpointpresentation-150601190927-lva1-app6892/85/Demand-Driven-MRP-10-320.jpg)

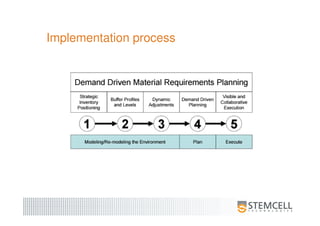

![11

Part 3. Lunching DDMRP [ 30분분분분 ]

The Five Components of DDMRP

Demand Driven Material Requirements Planning

Strategic

Inventory

Positioning

1

Buffer Profiles

and Levels

2

Dynamic

Adjustments

3

Demand

Driven

Planning

4

Visible and

Collaborative

Execution

5

Modeling/Re-modeling the Environment Plan Execute](https://image.slidesharecdn.com/erikbushpowerpointpresentation-150601190927-lva1-app6892/85/Demand-Driven-MRP-11-320.jpg)