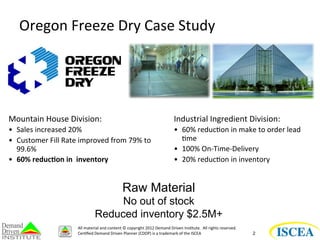

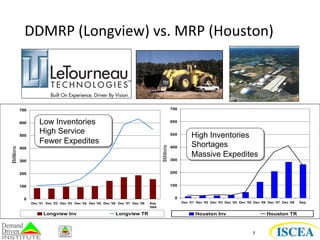

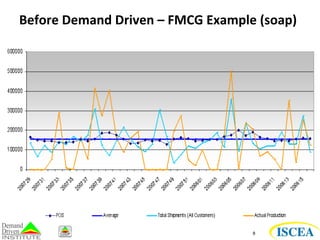

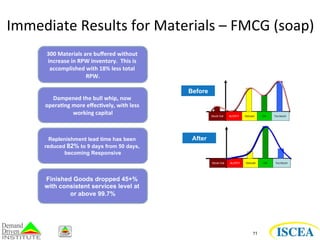

This document contains several case studies and examples of companies that implemented Demand Driven Material Requirements Planning (DDMRP). Key results of DDMRP implementation included reducing inventory levels by 20-60% while improving on-time delivery and customer fill rates. For example, an industrial ingredients division reduced make-to-order lead time by 60% and inventory by 20% while achieving 100% on-time delivery.