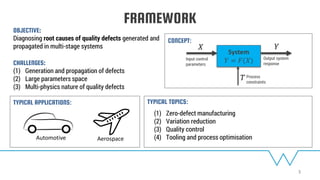

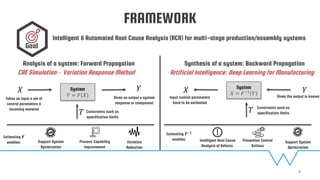

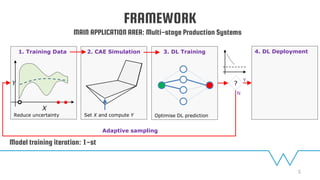

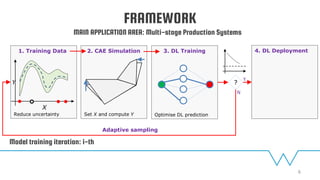

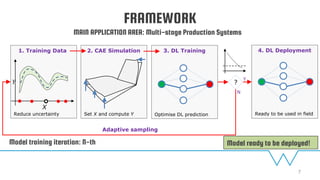

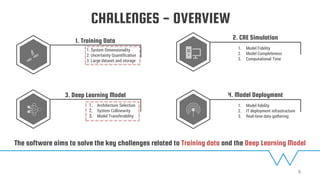

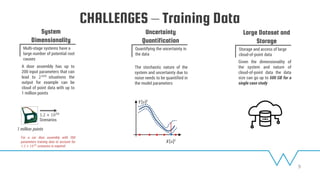

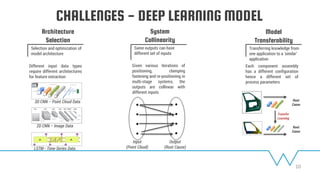

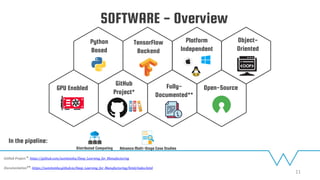

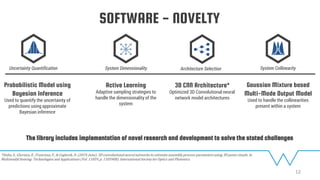

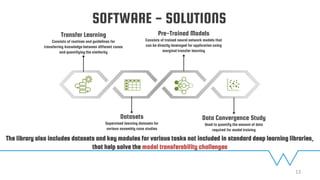

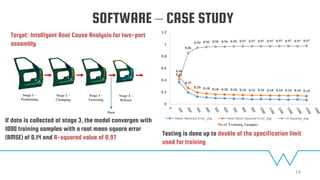

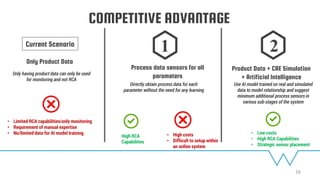

The document discusses using deep learning and artificial intelligence to predict and prevent manufacturing defects. It presents a framework that uses CAE simulation and deep learning to model the relationship between input control parameters and output system responses for multi-stage production systems. This enables intelligent root cause analysis of defects by estimating input parameters given an output. The approach aims to solve challenges like high dimensionality, data uncertainty, and model transferability. Software called Deep Learning for Manufacturing is presented that implements solutions like adaptive sampling and 3D CNNs to address these challenges. Potential competitive advantages include improved quality, productivity, and reduced costs through increased root cause analysis capabilities.