Geo Publication No. 1/2023 provides updated guidelines on deep excavation design and construction in Hong Kong, reflecting advancements in methods and technology since the previous standard published in 1990. This document aims to enhance economic design, reduce construction time, and improve ground deformation monitoring. It consolidates experiences from various stakeholders and encourages field monitoring to ensure the safety and effectiveness of excavation works.

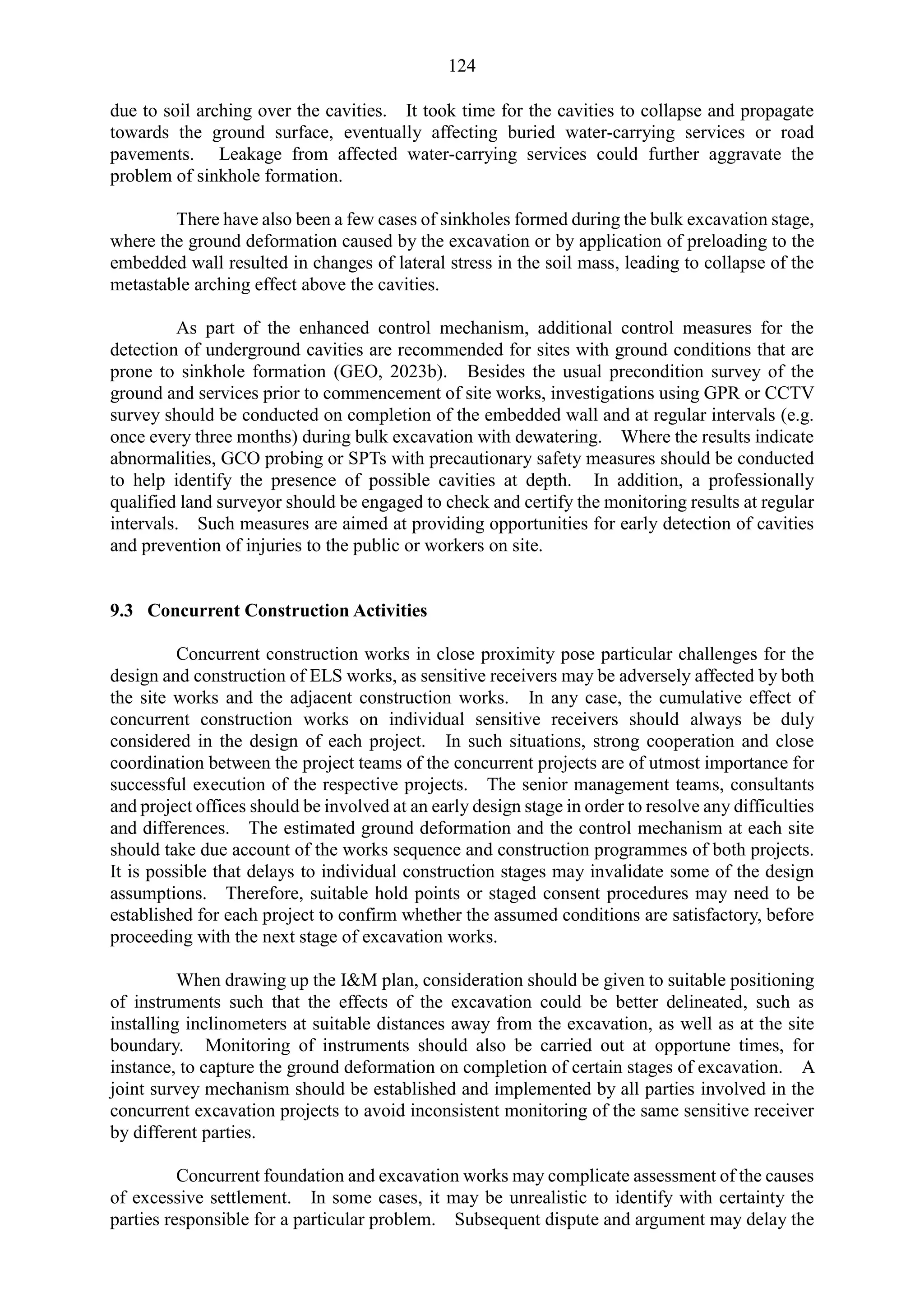

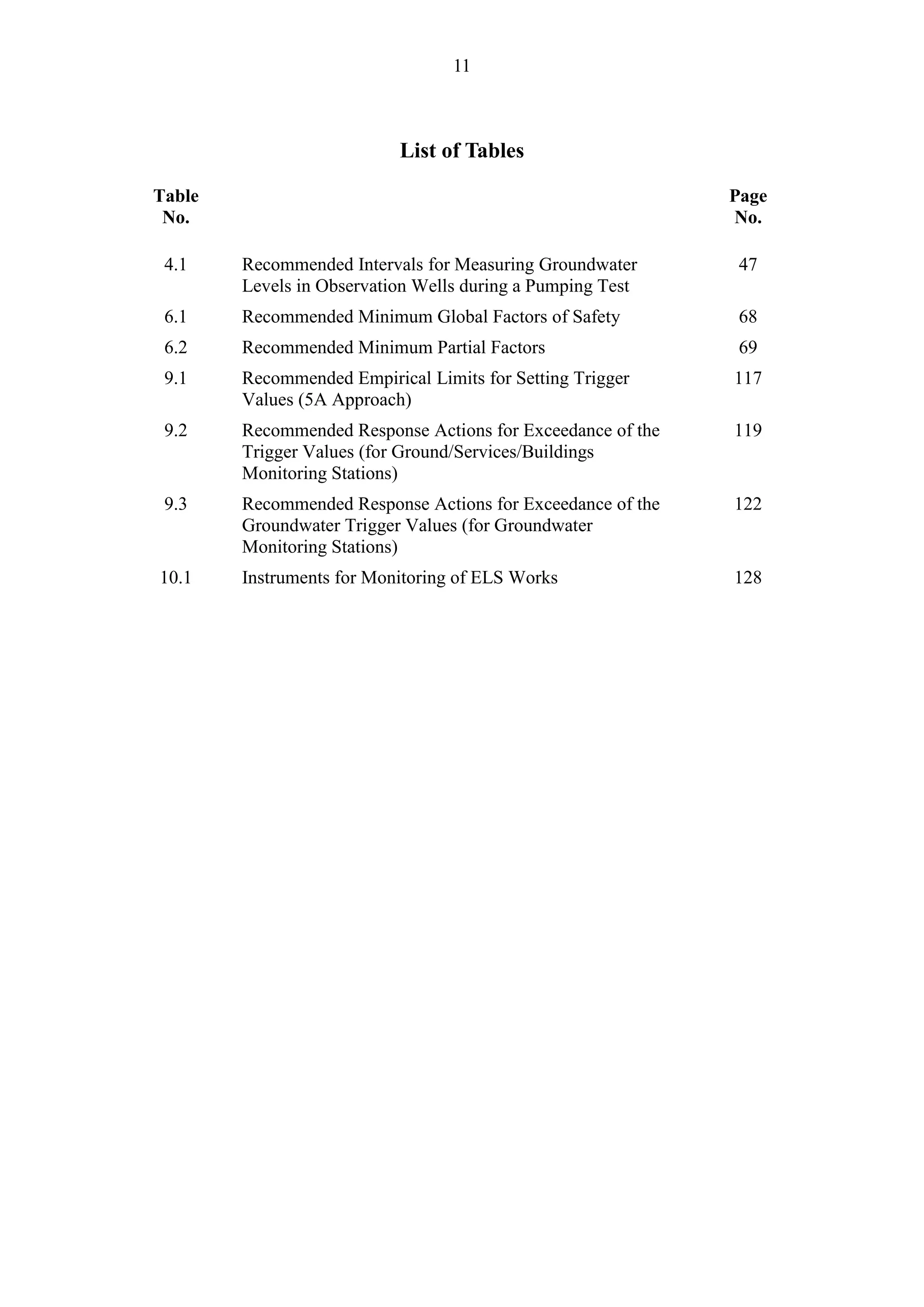

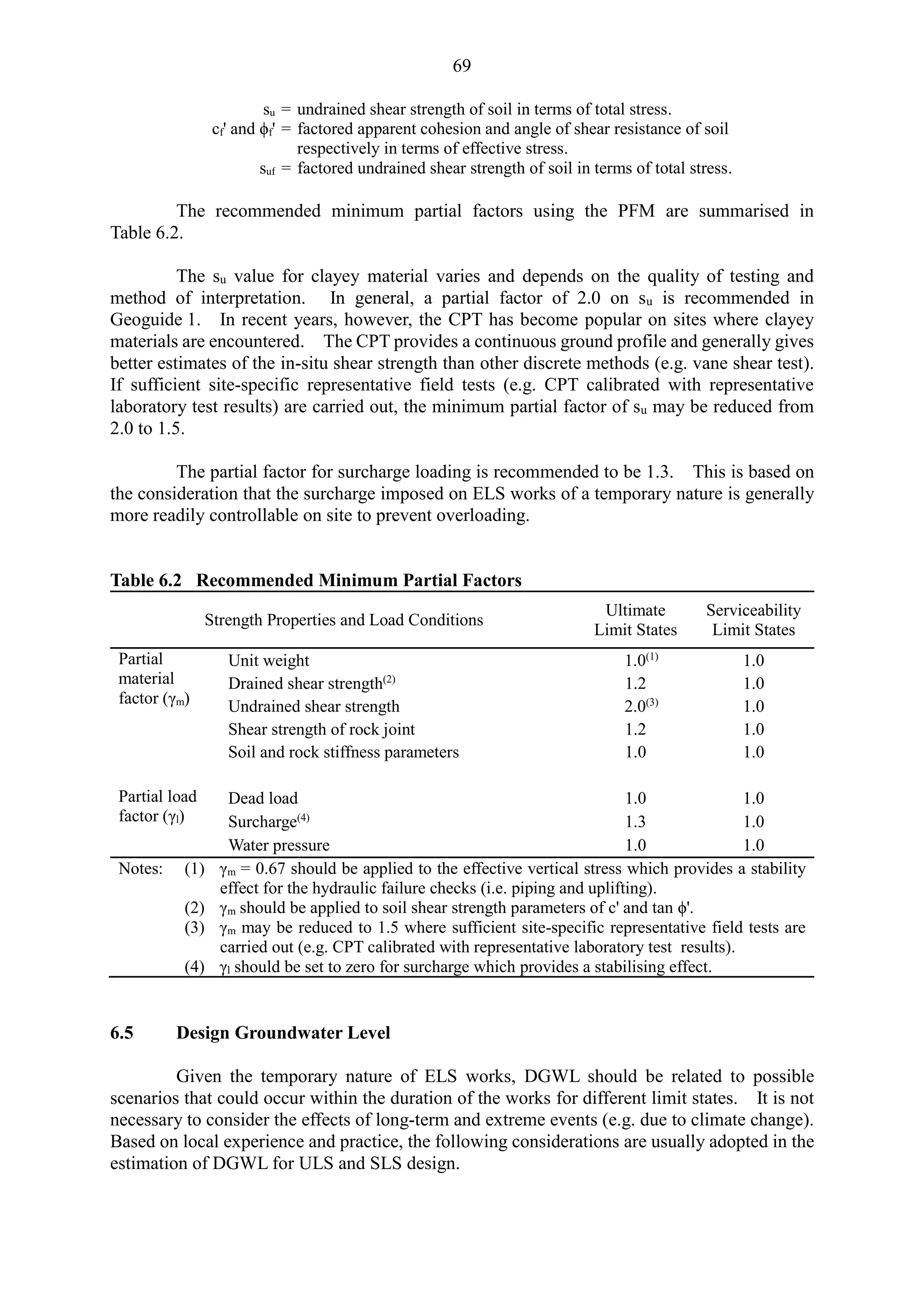

![87

GFM:

hw + ( - w)z

u

≥ Required global factor of safety in Table 6.1

PFM: u mhww) z]

where uo = Groundwater pressure in the absence of flow

ud = Design groundwater pressure in the presence of flow

u = Pressure difference

= Bulk unit weight of soil

w = Unit weight of water

m = Partial material factor in Table 6.2

Figure 7.10 Method of Piping Analysis (modified from BSI, 2022)

GFM:

h1 + h2

ua

≥ Required global factor of safety in Table 6.1

PFM: ua m (1h1 + 2h2)

where 1h1 + 2h2 = Total stress at the depth of (h1 + h2) on excavated side

ua = Groundwater pressure determined from seepage analysis

Figure 7.11 Method of Uplifting Analysis (modified from Ou, 2006)

h1

Impermeable layer

GWL

h2

Permeable layer

Permeable layer

ua

GWL

u

hw

ud

uo

z

ud

Dewatering level

GWL

GWL](https://image.slidesharecdn.com/deepexcavationdesignandconstruction2023-240730130925-ea0fe50c/75/Deep-Excavation-Design-and-Construction-_2023-pdf-87-2048.jpg)

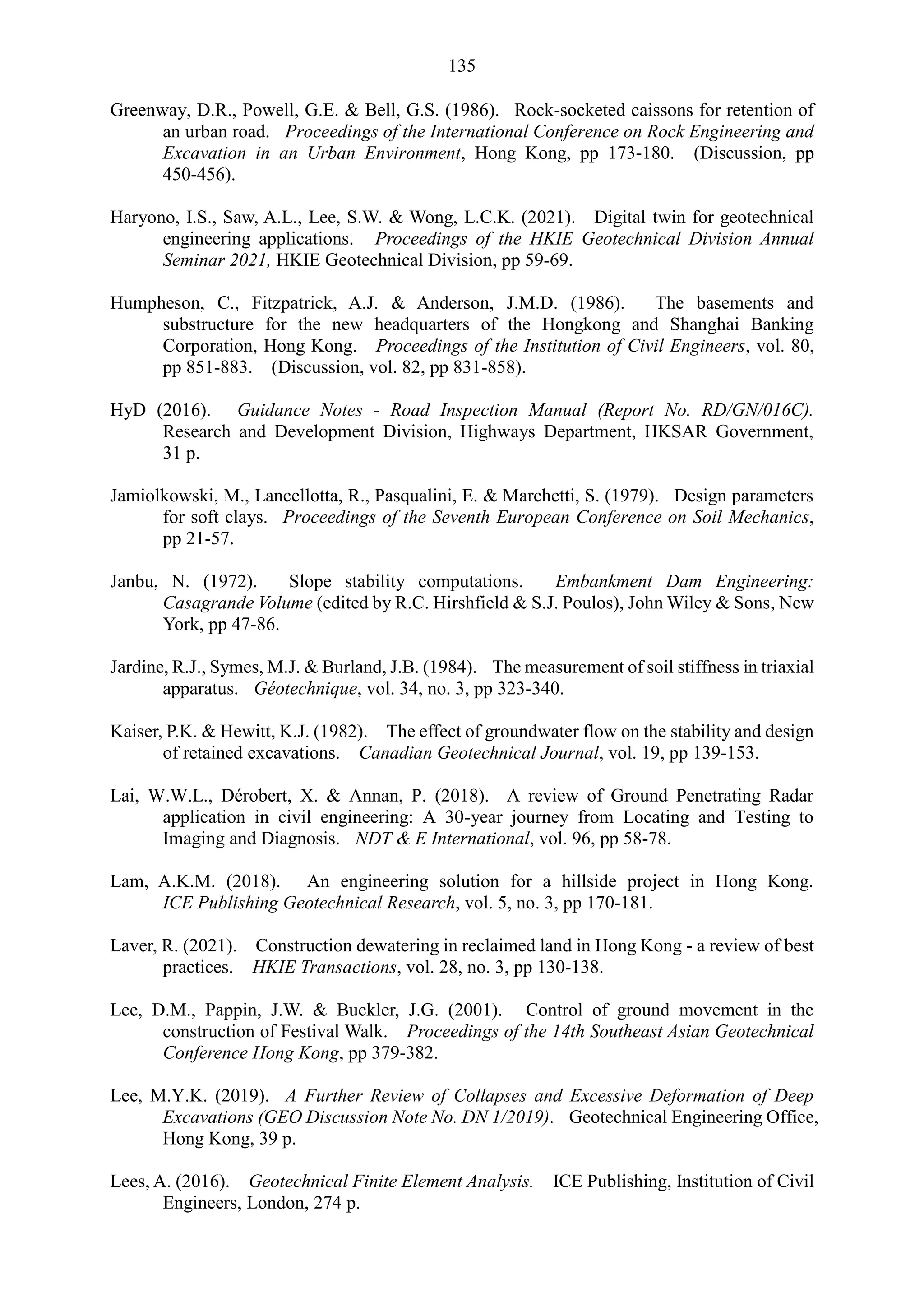

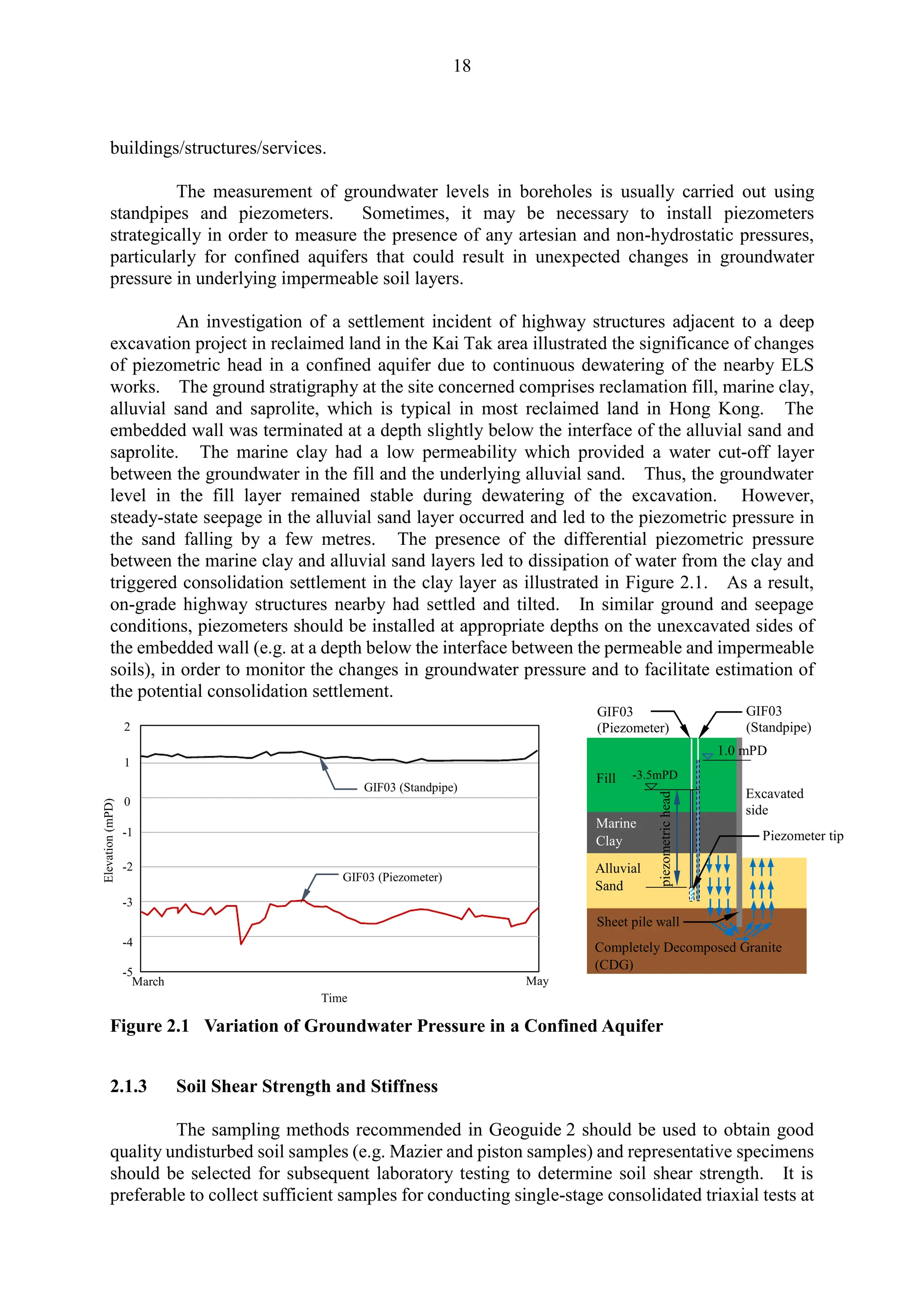

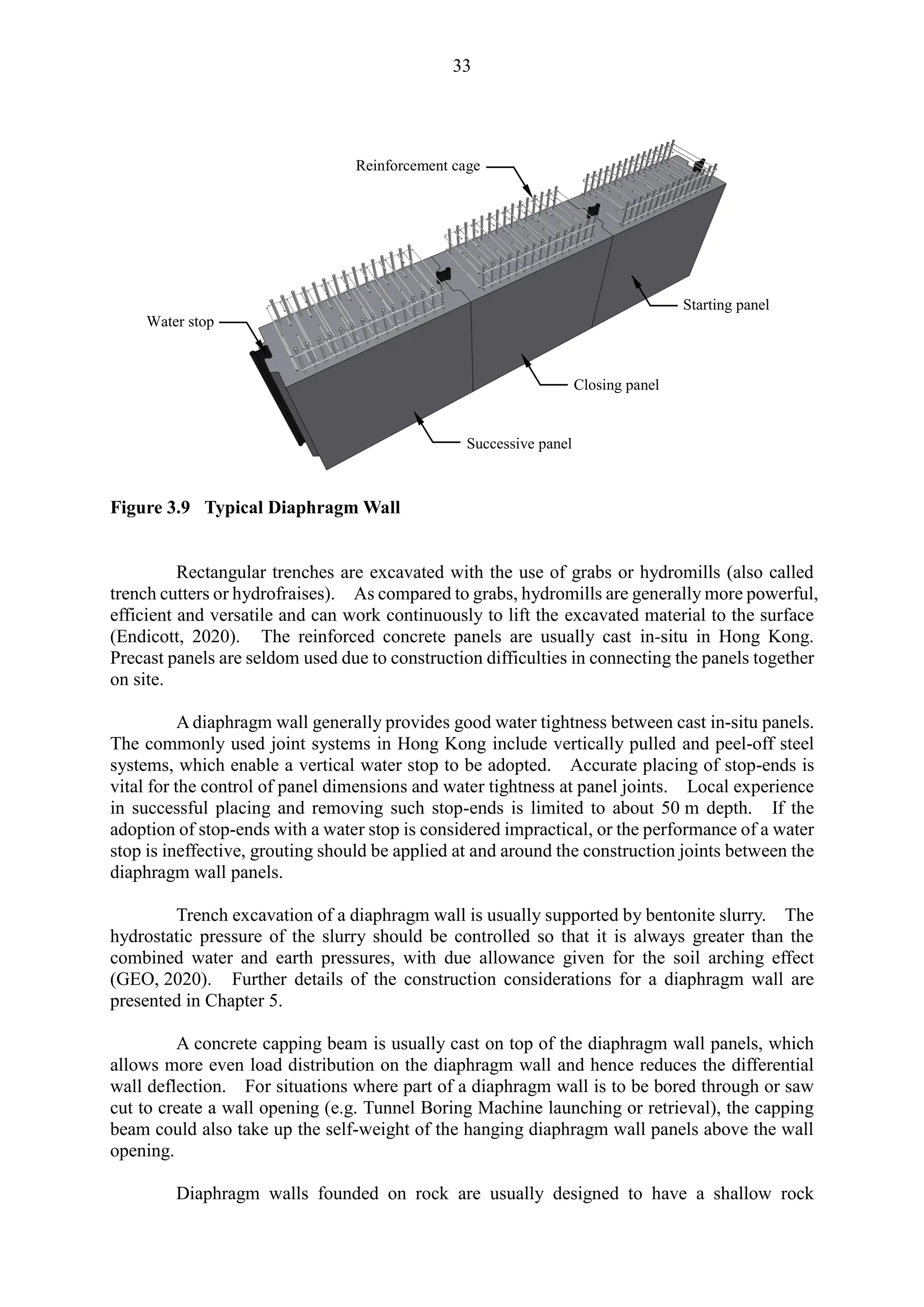

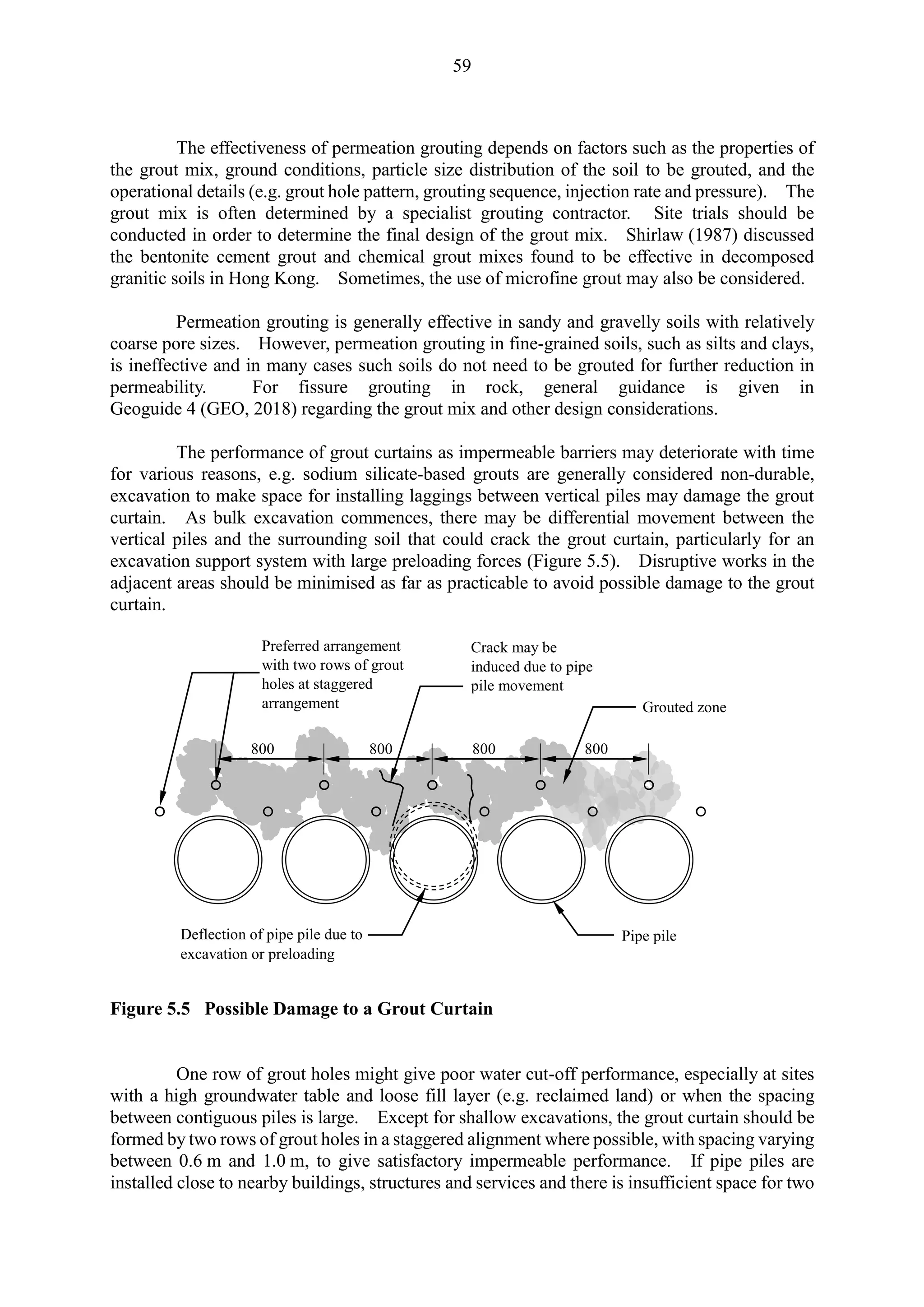

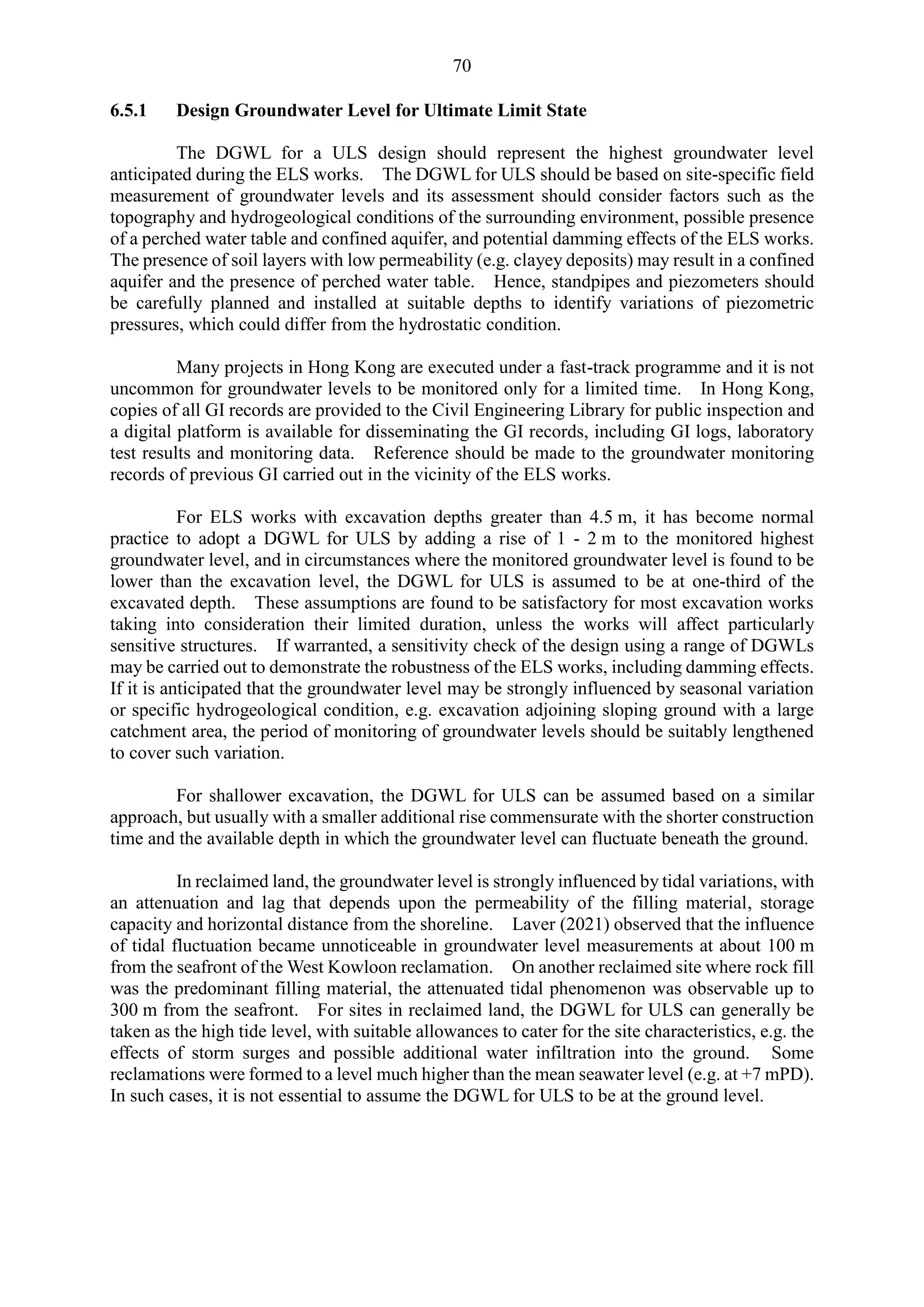

![101

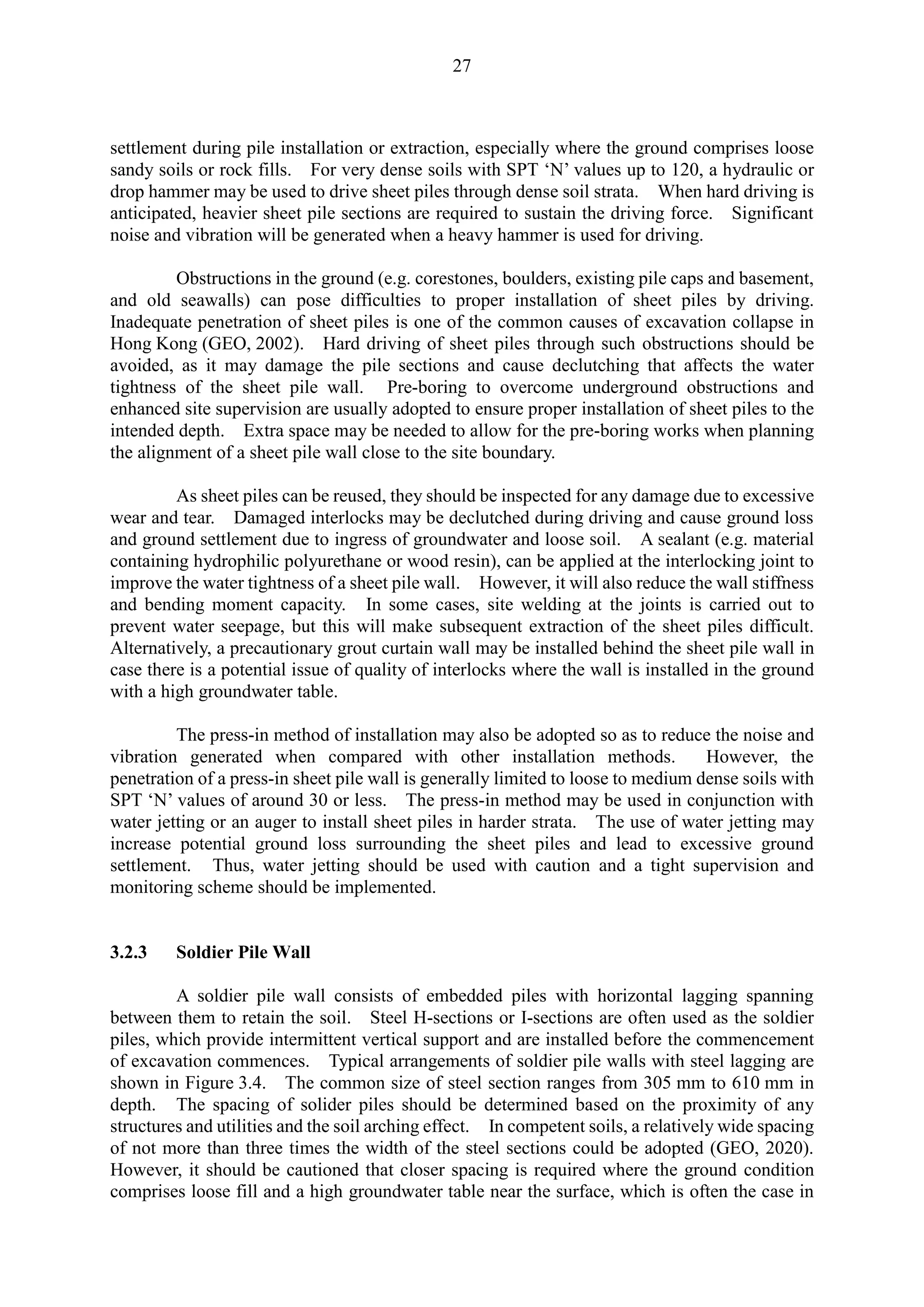

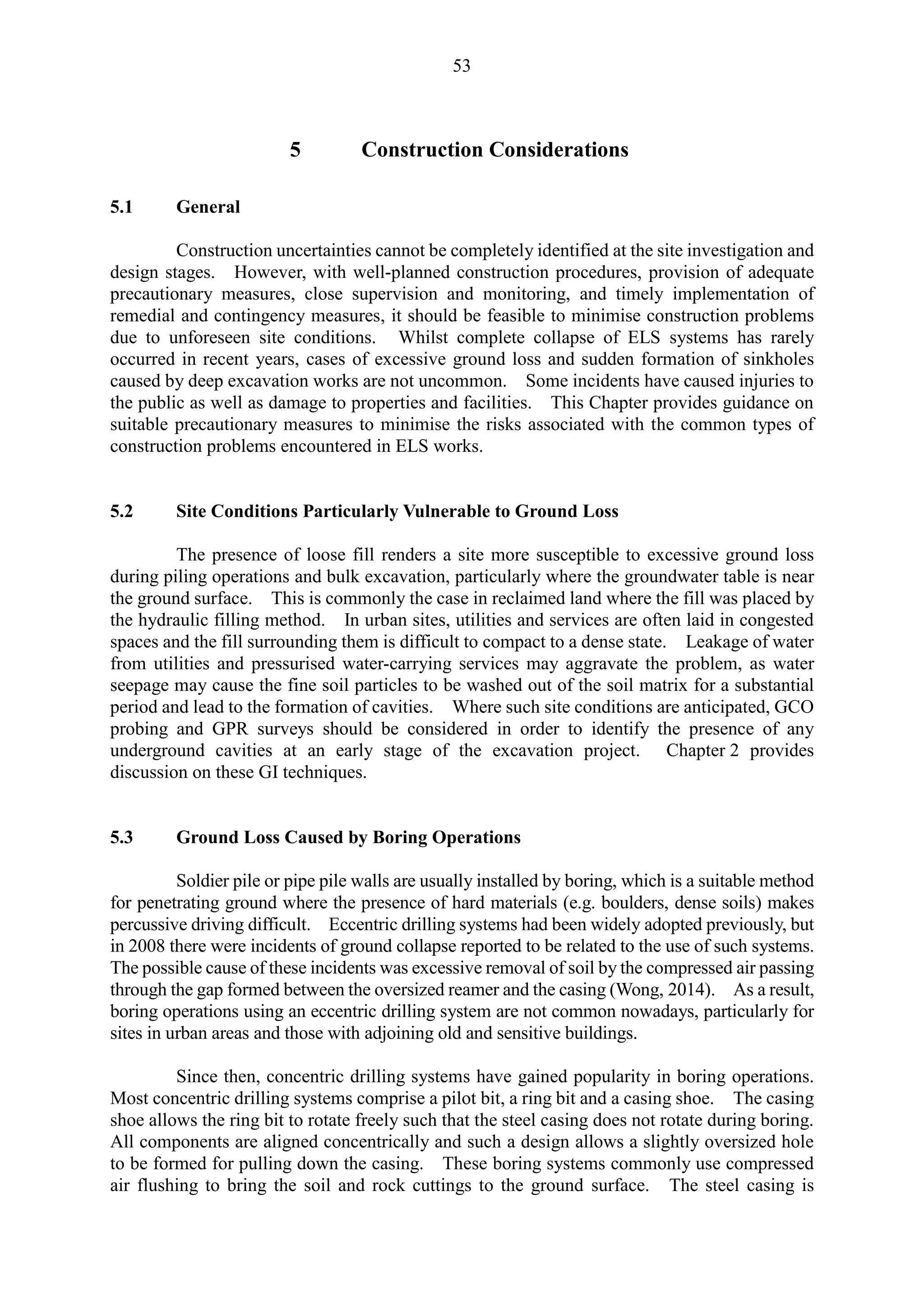

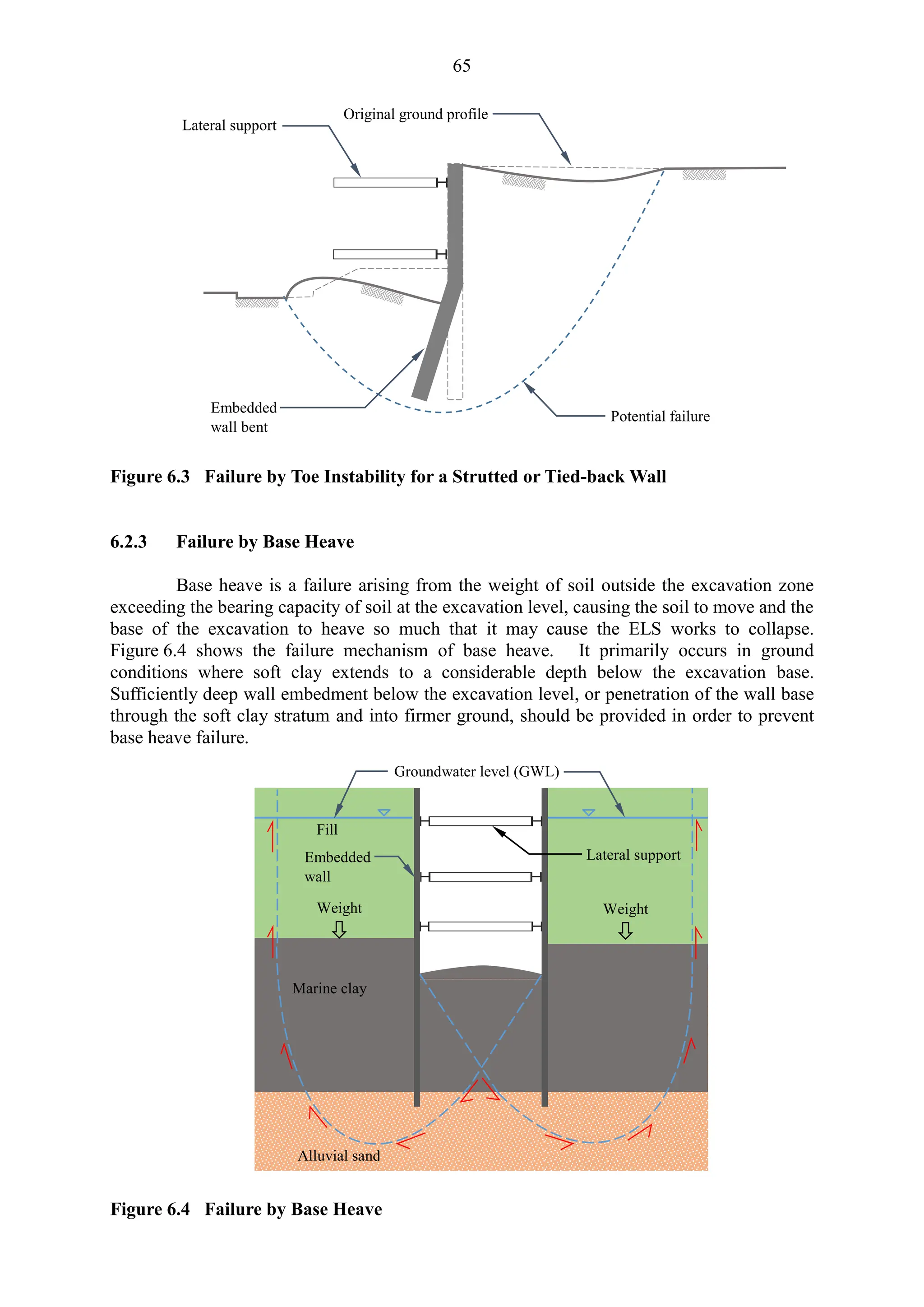

ground deformation was caused by a rise in the groundwater table as a result of the construction

of preceding wall panels, which reduced the effective slurry pressure supporting the subsequent

trench excavations. Pickles et al (2003) reported that the large ground settlement observed

during the diaphragm wall construction for the Tsuen Wan West Station was mainly associated

with the cobbles and boulders encountered in the buried old seawall structures. In a case

where ground improvement works were carried out prior to trenching at the roadworks at Kwun

Tong, the induced ground settlement was only 0.02%Ht, which was about 10 mm (Figure 8.2).

Figure 8.2 Measured Ground Settlement due to Diaphragm Wall Installation from Case

Study Data

It is recommended that for estimating the effects of diaphragm wall panel construction,

a minimum ground settlement of about 0.05%Ht should be allowed for when assessing the

impact on nearby sensitive receivers. However, where the trench excavation involves removal

of corestones in saprolite or buried man-made ground features, a higher prescribed value may

be more appropriate. In competent ground conditions (e.g. dense saprolite), or if ground

improvement works have been implemented prior to trenching, the induced ground settlement

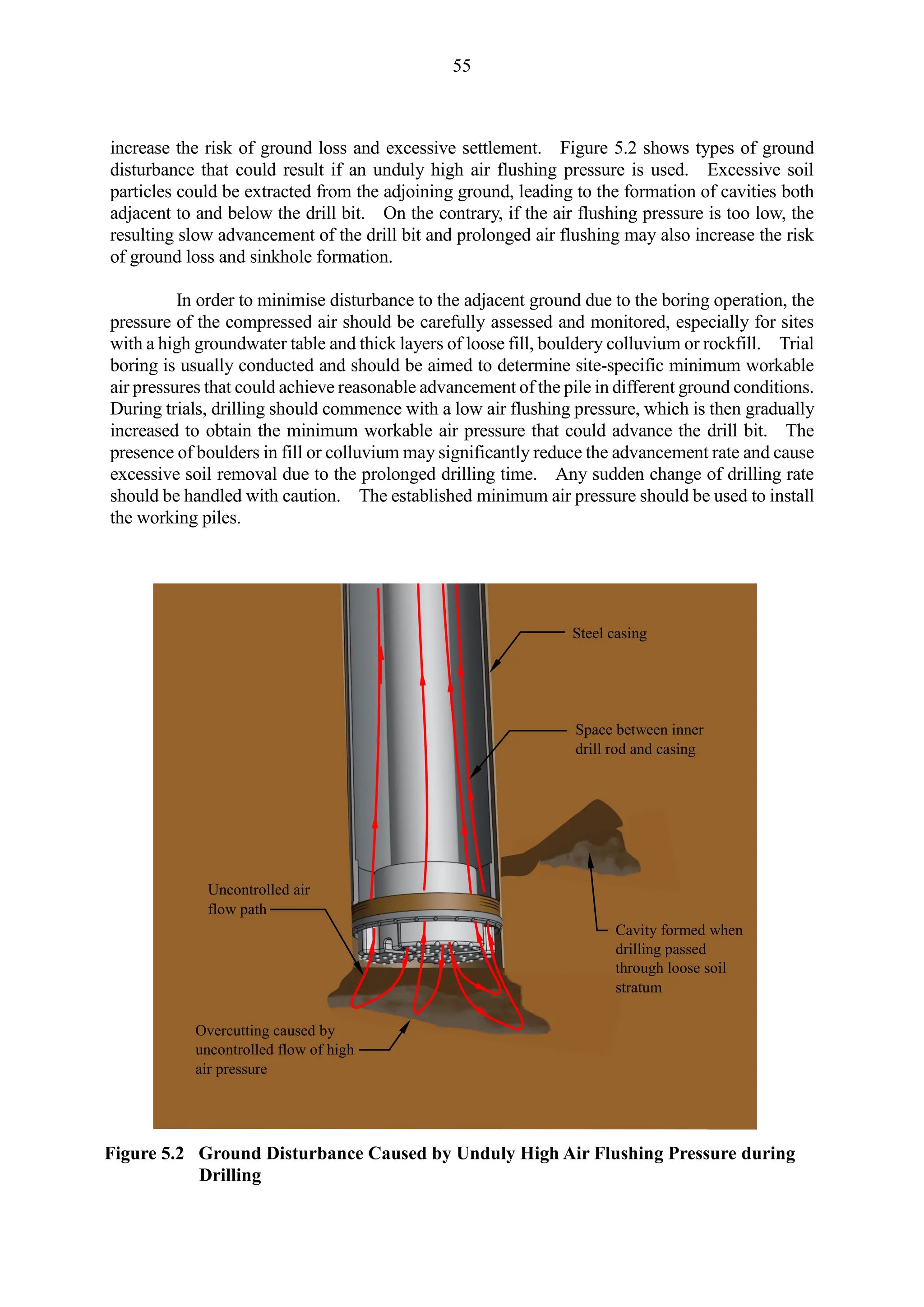

due to diaphragm wall installation might be less than the nominal value of 0.05%Ht. On the

other hand, ground settlement can be also assessed using either an empirical approach (e.g. by

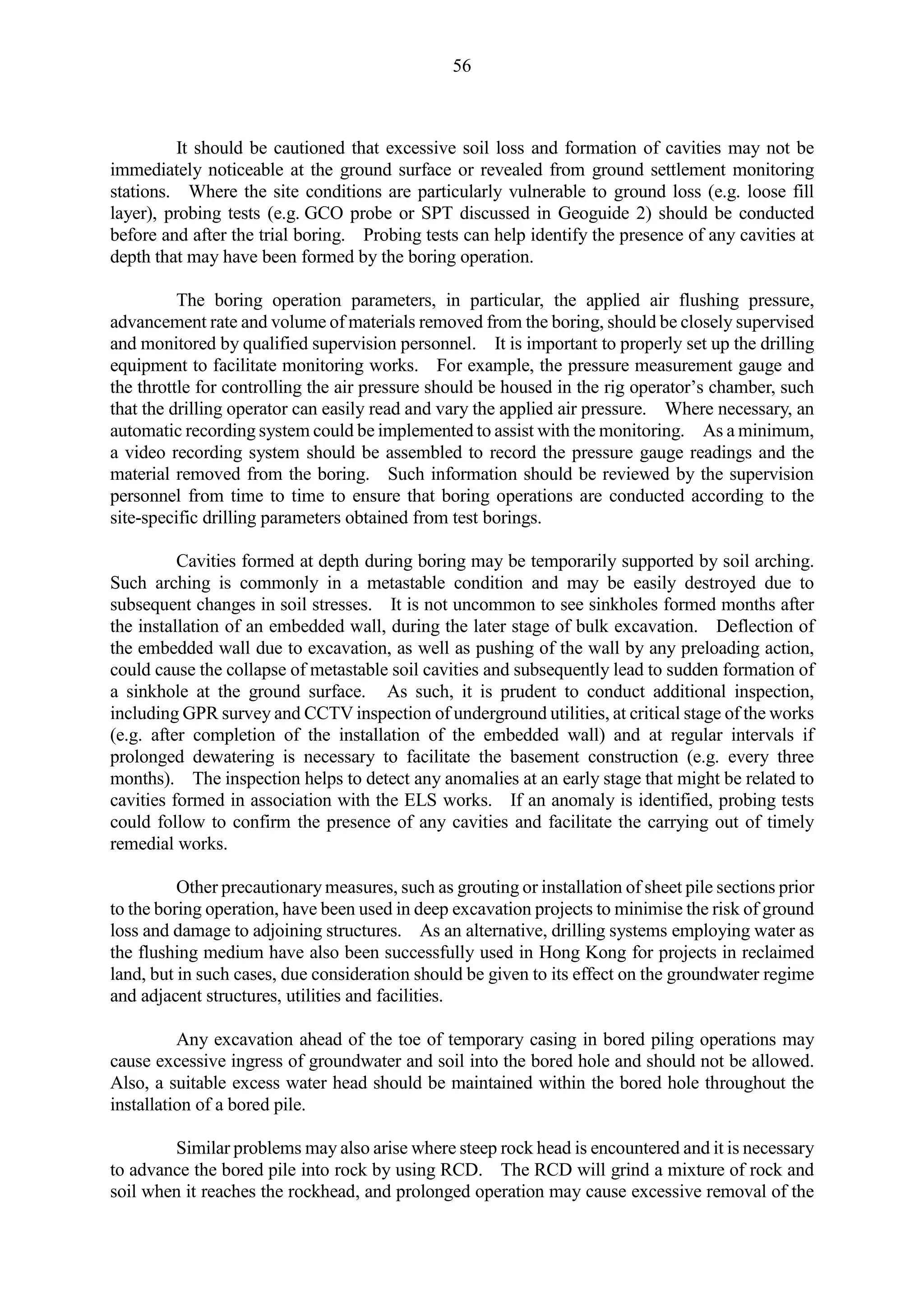

referring to previous projects with similar ground conditions and wall panel geometry) or by a

numerical method. Site-specific trials should be undertaken to confirm the design slurry

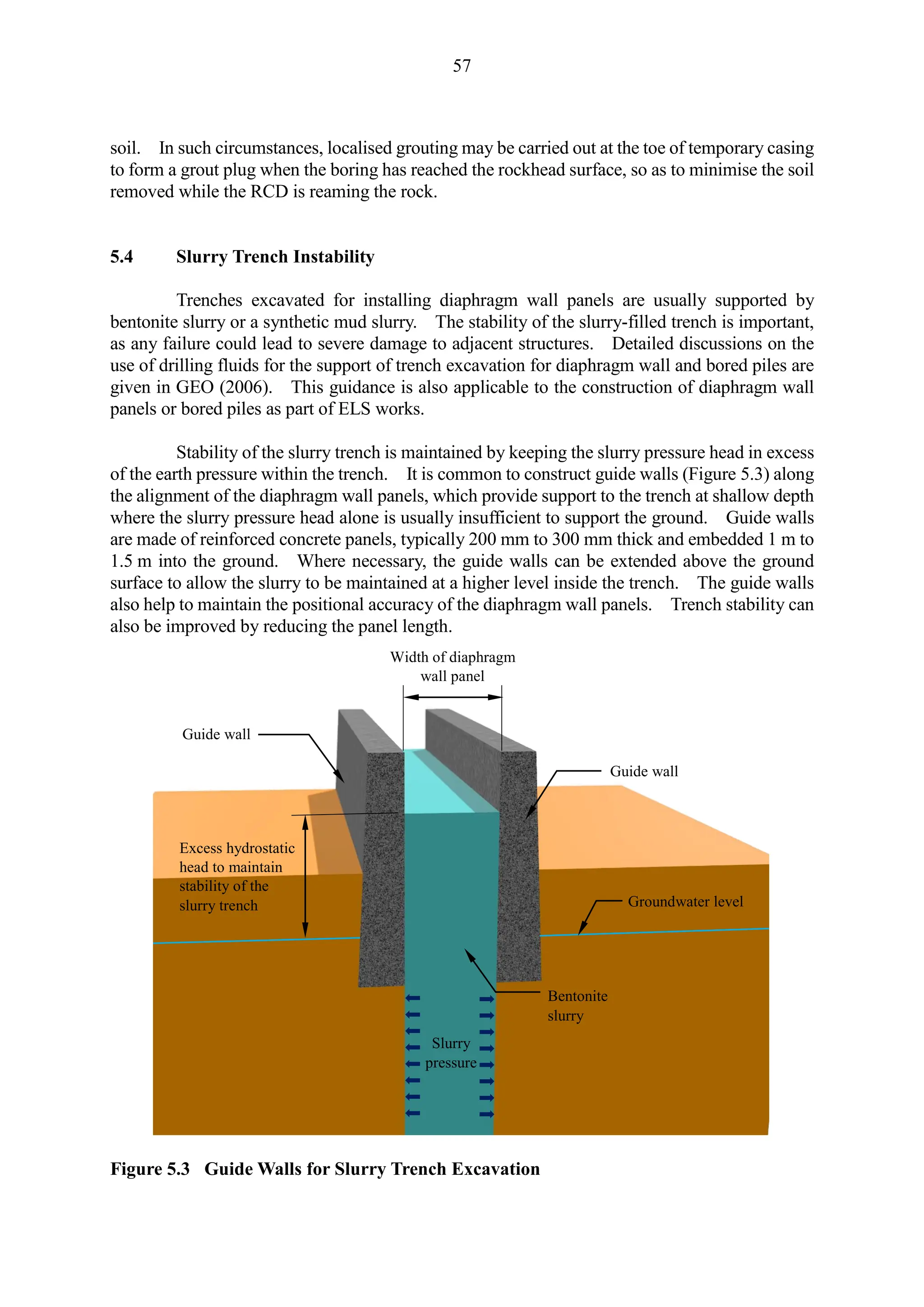

pressure and the induced ground deformation.

Advanced numerical models have been used by some researchers to estimate the

ground deformation caused by the installation of driven or bored piles. However, applications

of such models in practice are still limited because of the simplifications and assumptions that

0

0.05

0.1

0.15

0.2

0.25

0.3

20 25 30 35 40 45 50

Settlement

due

to

wall

installation,

δ

v

/H

t

(%)

Diaphragm wall depth, Ht (m)

Chater Station, HK [37m]

HSBC HQ [30m]

Tsuen Wan West Station (old reclamation) [22m]

Sheung Wan Crossover [43m]

Tsuen Wan West Station (new reclamation) [35m]

Development at Admiralty [39m]

Development at To Kwa Wan [42m]

Roadworks at Kwun Tong [49m]

10 mm

20 mm

30 mm

Note: Value in bracket represents Ht](https://image.slidesharecdn.com/deepexcavationdesignandconstruction2023-240730130925-ea0fe50c/75/Deep-Excavation-Design-and-Construction-_2023-pdf-101-2048.jpg)