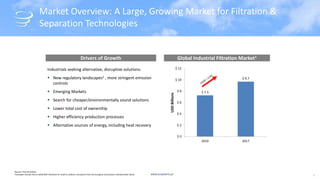

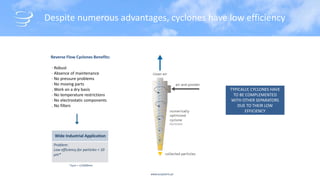

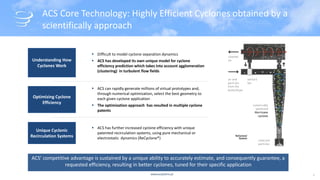

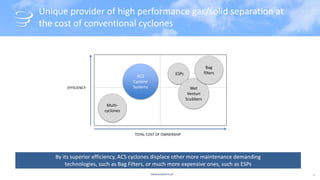

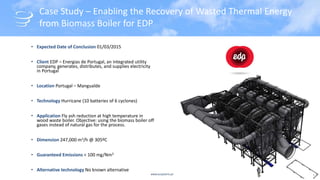

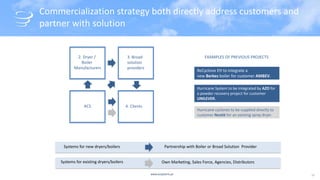

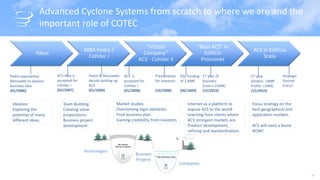

The document discusses filtration and separation technologies that address emissions control needs and powder recovery needs in various industries. It notes increasing regulations on particulate matter emissions and the need for industries like steel, cement, and power plants to control emissions. Many processes also generate powder waste that can be recovered. The company, ACS, describes their core cyclone technology that offers higher efficiency than traditional cyclones through modeling and design optimization. They have over 120 installations globally in industries like pharmaceuticals, food, chemicals, and more. ACS discusses their commercial strategy of working directly with customers and partners.