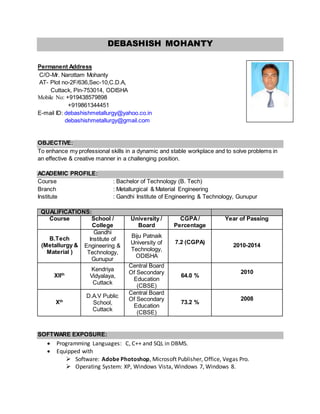

This document contains Debashish Mohanty's resume. It summarizes his contact information, objective, academic qualifications, software skills, projects, achievements, hobbies, skills, work experience and declaration. Mohanty has a Bachelor of Technology degree in Metallurgical & Material Engineering. He has work experience in the Continuous Galvanising & Galvalume Line of Bhushan Power & Steel Ltd, where he helped process the thinnest material and commission a new galvalume line.