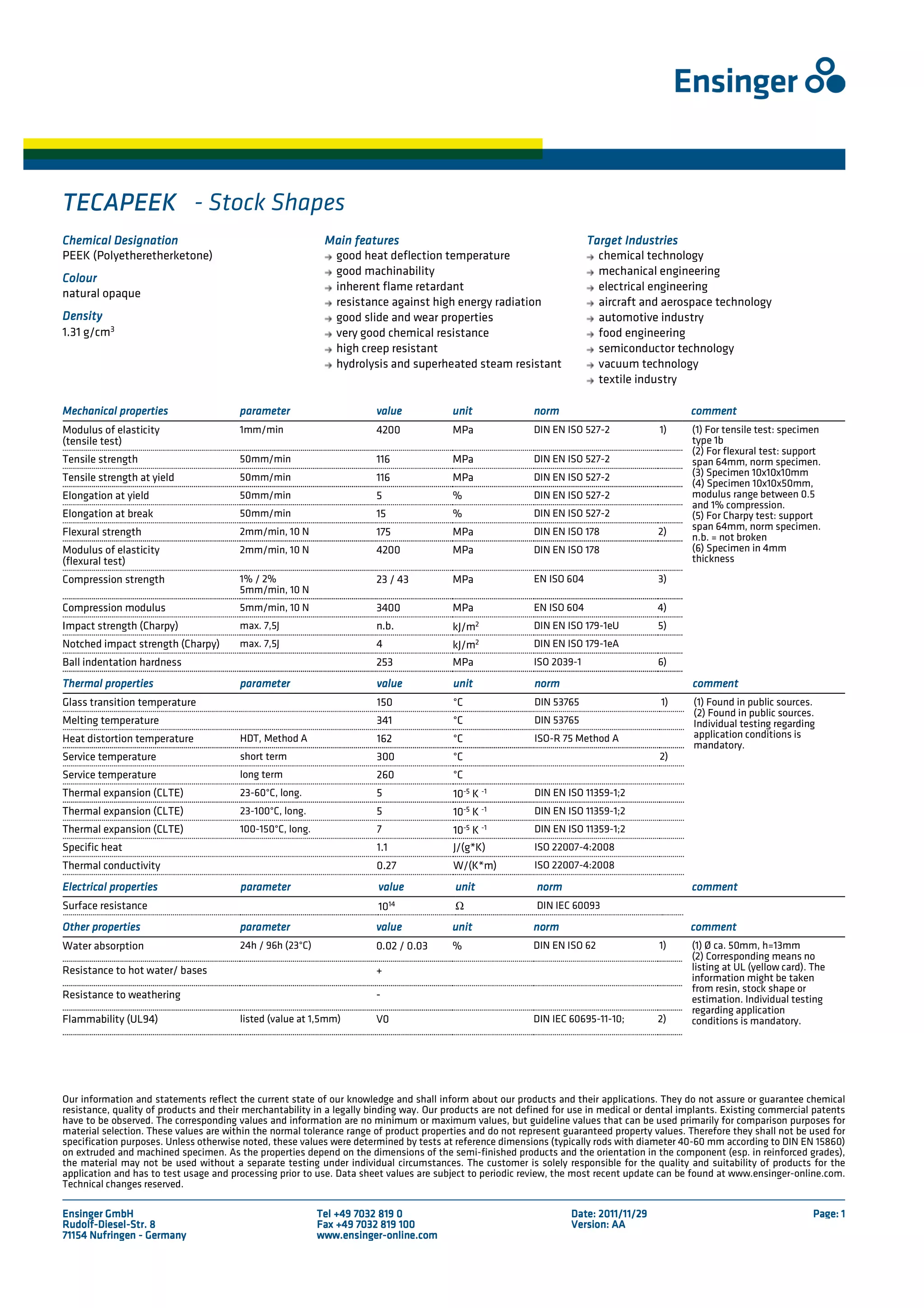

TECAPEEK is a polyetheretherketone (PEEK) polymer stock shape known for its heat resistance, chemical resistance, and mechanical properties. It has a high heat deflection temperature, is machinable, flame retardant, and resistant to radiation and chemicals. TECAPEEK finds applications in industries including chemical technology, mechanical engineering, electrical engineering, aerospace, automotive, food processing, and semiconductors due to its strength, durability, and ability to withstand high temperatures and harsh chemicals. The document provides extensive data on the material properties of TECAPEEK including mechanical, thermal, electrical properties and specifications.