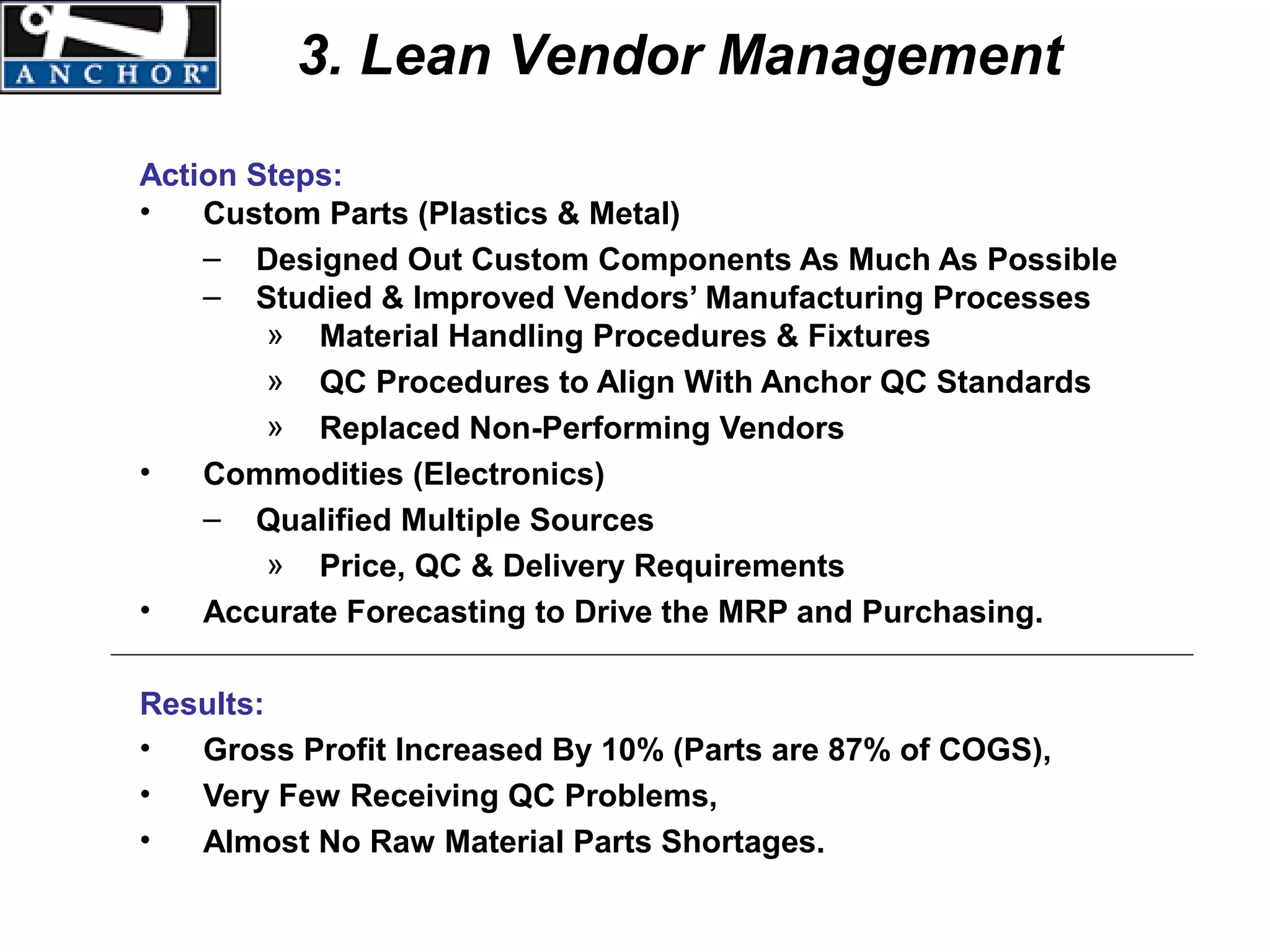

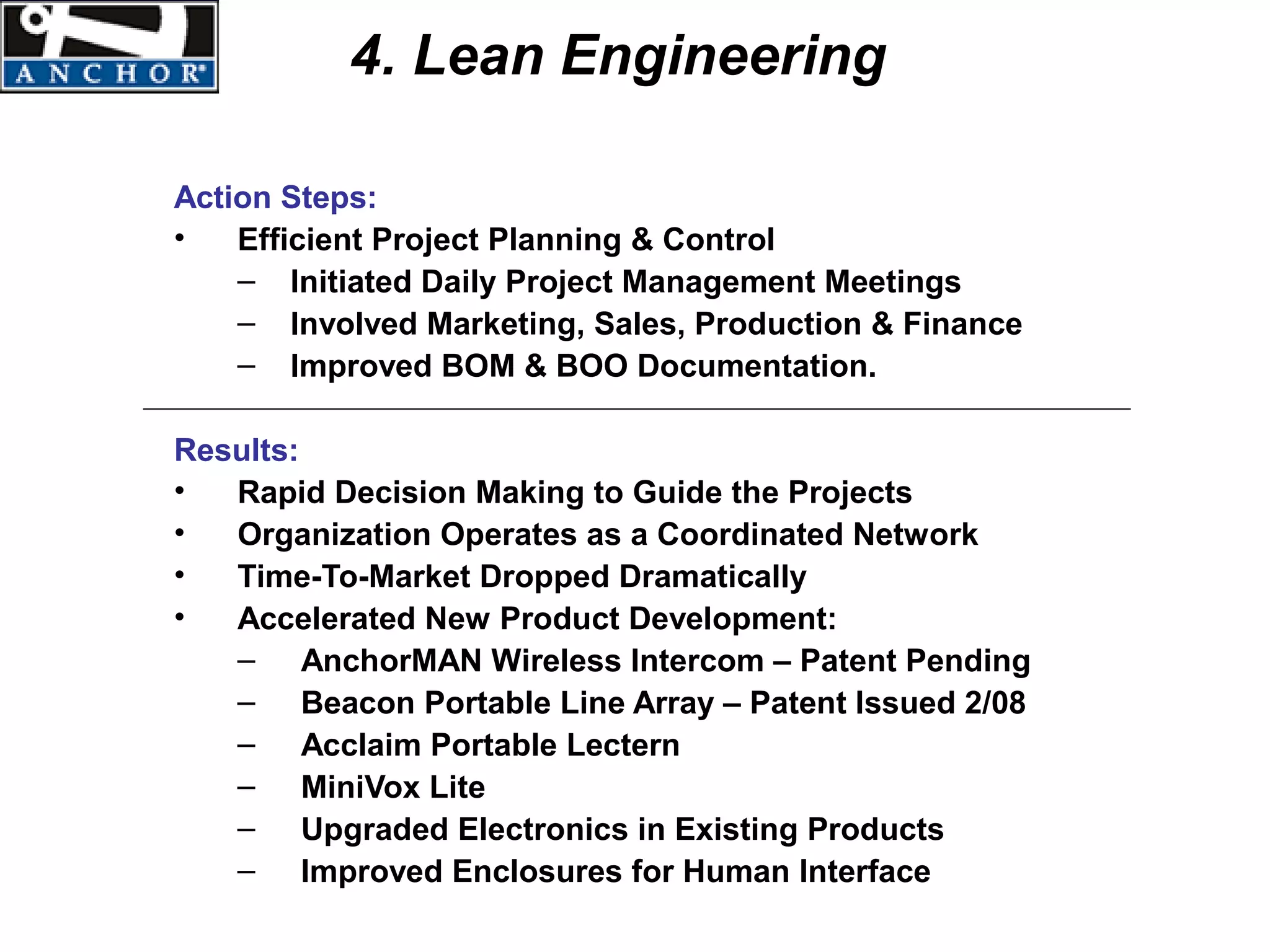

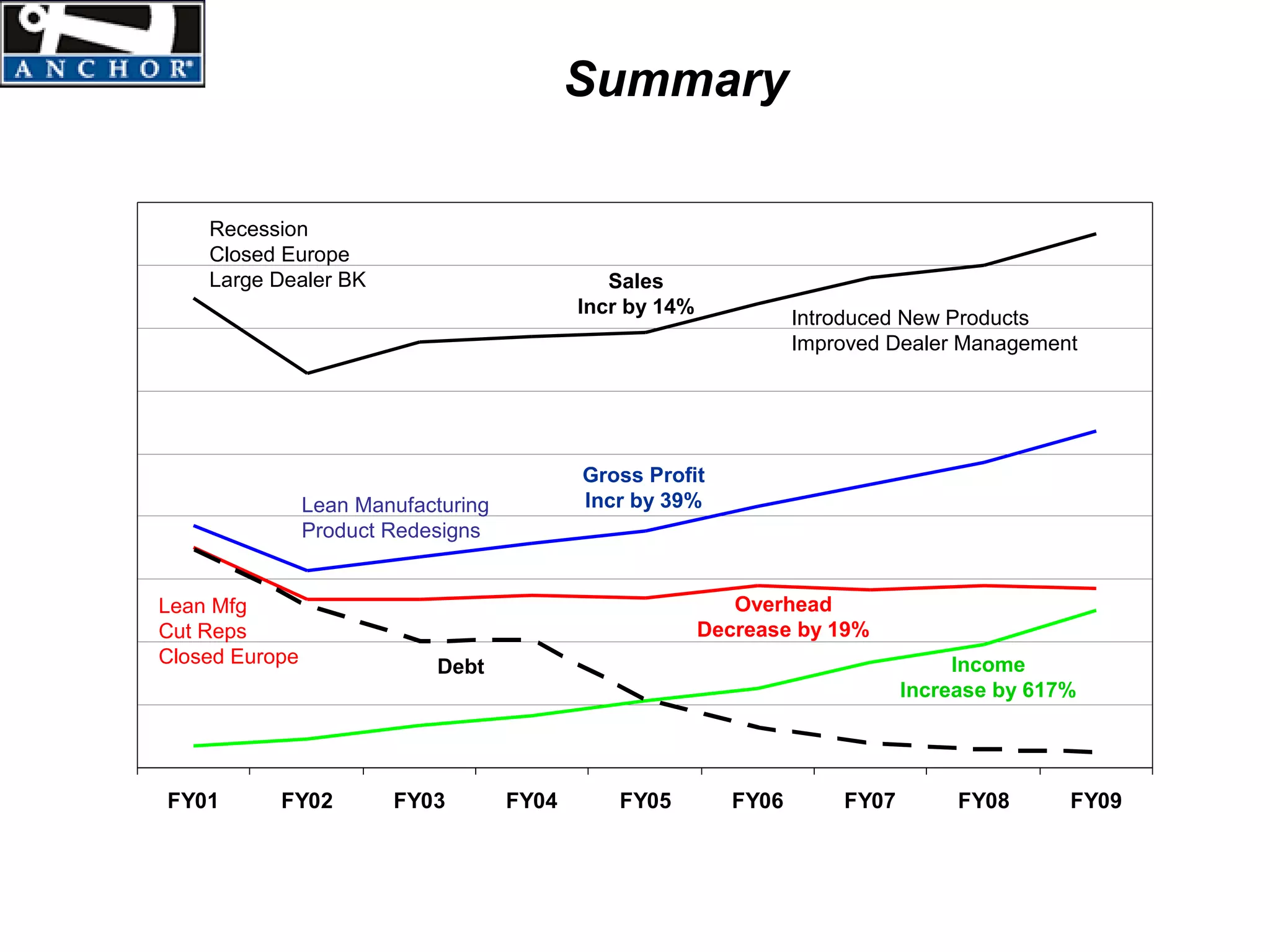

David Jacobs, chairman of Anchor Audio, discussed how the company uses lean business management strategies to succeed against foreign competitors. These strategies include lean manufacturing to reduce costs by 50% and inventory by 45%, lean distribution such as firing manufacturer reps to improve dealer support, lean vendor management to increase gross profits by 10%, lean engineering to reduce time-to-market, and lean finance to eliminate outside debt and funding for growth. As a result of these lean initiatives, Anchor Audio has seen sales increase 14%, gross profits increase 39%, overhead decrease 19%, and income increase 617%.