Data Processing

•

0 likes•70 views

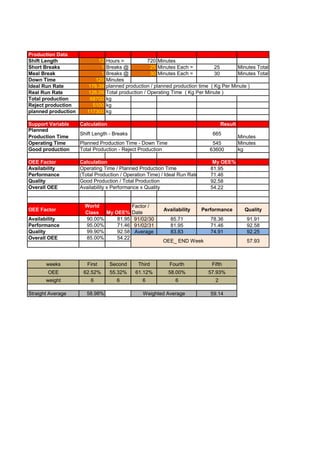

The document provides production data from a manufacturing shift including shift length, break times, downtime, production rates, output, and OEE calculations. It analyzes the availability, performance, quality, and overall OEE percentage for the shift which was 54.22%. OEE percentages for the last 5 weeks are also shown, with the weighted average being 59.14%.

Report

Share

Report

Share

Download to read offline

Recommended

To boilerplate v8 1 mayl2012

This document discusses mobility and mobile device management. It notes that constant access to data is critical, 87% of employees use personal devices for work, and the traditional workstation model is gone. It highlights security threats to mobile data like lost or stolen devices. The document promotes a mobile device management solution that provides device, application, and document management features as well as 24/7 support to securely manage employee mobility and address bring-your-own-device trends in business.

P.Meiring CV LinkedIn

Peter Meiring had a long career in business, holding several positions at TFG Limited including Supervisory Board director, Operating Board Director, and Chairman of RCS (Pty) LTD. He was responsible for consumer financial services, web services, marketing, mobile devices, and customer services. In 1999, he started RCS which provided consumer credit services and later sold a stake in the business, negotiating its full sale in 2014 for $2.65 billion. Throughout his career, he launched several successful programs including Rewards & More and ONE 2ONE. He has extensive experience in retail, consumer credit, and management.

EPM_selfpromo_generic_2015-04-30

This document provides information about EP&M International, an exhibit design and event management company. It summarizes their services, global locations, awards, and experience designing exhibits worldwide for trade shows, corporate events, interactive displays, and permanent installations. They offer full-service support including design, fabrication, logistics, and on-site supervision for exhibits of any size or location.

Presentacion feria artesanal Rio Ceballos

La ordenanza 2065/13 fue construida colectivamente por artesanos y el municipio para regular el espacio de ferias artesanales. Se estableció una Comisión de Ferias conformada por artesanos y el municipio para tomar decisiones sobre el uso del espacio, canon, fiscalización y más. La ordenanza reconoce las artesanías como patrimonio cultural y a los artesanos como protagonistas, buscando condiciones dignas para su trabajo y preservando la feria como atractivo cultural.

Smartech

Interested in Smartech? Have some questions? This will represent our Company, Products and Services and how to contact us!

Mis deseos de año nuevo

Este documento desea un feliz año nuevo y que la amistad continúe siendo fuerte y especial. También desea que haya pocas lágrimas y mucha alegría compartida, y que Dios guíe a las personas por el camino correcto eliminando sentimientos negativos. Finalmente, desea que el amor por los demás sea la meta principal.

Practicando habildades de liderazgo en el club

El autor argumenta que Toastmasters ha sido durante mucho tiempo una organización fuerte para desarrollar líderes, aunque no había formalizado explícitamente las habilidades y enfoque del liderazgo. Explica que las habilidades fundamentales del liderazgo, como enfocarse en los problemas y no en las personas, y proteger la autoestima de los demás, son prácticas en cada reunión de Toastmasters a través de actividades como discursos y evaluaciones. Finalmente, pide a los miembros que creen un entorno donde se enfoquen en los

Cognitive Reasoning and Inferences through Psychologically based Personalised...

This presentation discusses developing personalized emotion models using associative classifiers. It begins with background on adaptive user interfaces and computational emotions. A new corpus was created with video recordings of people expressing basic emotions and affects. Initial analysis of Kinect data for happy expressions across subjects is shown. The approach explores generating individualized sets of rules linking facial action units using tree/rule classifiers like M5, with the goal of personalized emotion detection models.

Recommended

To boilerplate v8 1 mayl2012

This document discusses mobility and mobile device management. It notes that constant access to data is critical, 87% of employees use personal devices for work, and the traditional workstation model is gone. It highlights security threats to mobile data like lost or stolen devices. The document promotes a mobile device management solution that provides device, application, and document management features as well as 24/7 support to securely manage employee mobility and address bring-your-own-device trends in business.

P.Meiring CV LinkedIn

Peter Meiring had a long career in business, holding several positions at TFG Limited including Supervisory Board director, Operating Board Director, and Chairman of RCS (Pty) LTD. He was responsible for consumer financial services, web services, marketing, mobile devices, and customer services. In 1999, he started RCS which provided consumer credit services and later sold a stake in the business, negotiating its full sale in 2014 for $2.65 billion. Throughout his career, he launched several successful programs including Rewards & More and ONE 2ONE. He has extensive experience in retail, consumer credit, and management.

EPM_selfpromo_generic_2015-04-30

This document provides information about EP&M International, an exhibit design and event management company. It summarizes their services, global locations, awards, and experience designing exhibits worldwide for trade shows, corporate events, interactive displays, and permanent installations. They offer full-service support including design, fabrication, logistics, and on-site supervision for exhibits of any size or location.

Presentacion feria artesanal Rio Ceballos

La ordenanza 2065/13 fue construida colectivamente por artesanos y el municipio para regular el espacio de ferias artesanales. Se estableció una Comisión de Ferias conformada por artesanos y el municipio para tomar decisiones sobre el uso del espacio, canon, fiscalización y más. La ordenanza reconoce las artesanías como patrimonio cultural y a los artesanos como protagonistas, buscando condiciones dignas para su trabajo y preservando la feria como atractivo cultural.

Smartech

Interested in Smartech? Have some questions? This will represent our Company, Products and Services and how to contact us!

Mis deseos de año nuevo

Este documento desea un feliz año nuevo y que la amistad continúe siendo fuerte y especial. También desea que haya pocas lágrimas y mucha alegría compartida, y que Dios guíe a las personas por el camino correcto eliminando sentimientos negativos. Finalmente, desea que el amor por los demás sea la meta principal.

Practicando habildades de liderazgo en el club

El autor argumenta que Toastmasters ha sido durante mucho tiempo una organización fuerte para desarrollar líderes, aunque no había formalizado explícitamente las habilidades y enfoque del liderazgo. Explica que las habilidades fundamentales del liderazgo, como enfocarse en los problemas y no en las personas, y proteger la autoestima de los demás, son prácticas en cada reunión de Toastmasters a través de actividades como discursos y evaluaciones. Finalmente, pide a los miembros que creen un entorno donde se enfoquen en los

Cognitive Reasoning and Inferences through Psychologically based Personalised...

This presentation discusses developing personalized emotion models using associative classifiers. It begins with background on adaptive user interfaces and computational emotions. A new corpus was created with video recordings of people expressing basic emotions and affects. Initial analysis of Kinect data for happy expressions across subjects is shown. The approach explores generating individualized sets of rules linking facial action units using tree/rule classifiers like M5, with the goal of personalized emotion detection models.

Clearpath-Partnerships

Clearpath Solutions Group is an IT solutions provider that partners with technology leaders to customize solutions for storage, compute, backup/disaster recovery, networking, security, virtual desktops, and collaboration. They offer consulting, managed cloud services, and help manage IT budgets. Contact them at solutions@clearpathsg.com for assistance.

Top 10 Reasons Your CRF May Not Have Performed As Expected Final

1. Not accounting for the fertilizer and media displaced when transferring plants to larger containers can result in a lower fertilizer dose and shorter longevity.

2. Choosing a CRF longevity that is too short or long may cause slow growth - it should provide proper nutrition throughout the crop cycle.

3. The only way to find the best CRF formulation is through trialing under your own growing conditions since practices vary.

Metlityudi

The document summarizes a report on the structural material considerations for the first graving dock built in St. John's, Newfoundland in 1882. It discusses how a wooden design was chosen over stone after a thorough investigation by J.J. Little who visited dry docks in several American cities. Little's report favored wood based on shorter construction time, lower costs, and opinions he collected that said wood docks were more durable and effective than stone docks in cold climates. As a result, the Newfoundland government decided to use wood for the first graving dock in St. John's harbor.

RSB Henneke PD Training Program 031816

The document provides information about a Rock Steady Boxing program for people with Parkinson's disease offered at Title Boxing Club. It summarizes the instructor Kane Henneke's qualifications and experience in martial arts. It outlines the typical class format, which includes conditioning, drills, and techniques. Students progress through a graduated degree program involving different techniques as they test for new belt levels. The club promises a safe, diverse martial arts experience and satisfaction for students and families.

6072 18609-1-sm

O documento discute a simulação numérica e o método de experimentos planejados (DOE) aplicados para melhorar o processo de fundição sob pressão de ligas de alumínio. Inicialmente, simulações foram realizadas para identificar as causas de porosidade em uma peça. Em seguida, um DOE foi usado variando parâmetros de injeção para avaliar sua influência na qualidade da peça. Resultados experimentais selecionados foram simulados numericamente para comparação.

Emotions Modelling and Synthetic Characters

Dr. Aladdin Ayesh presents on emotions modelling and synthetic characters. He discusses some key issues in emotions modelling like selecting emotions to represent, expressing emotions, and recognizing emotions from facial expressions and other cues. He outlines some of his research projects in this area, including computational models of emotion and emotionally expressive communication languages.

Región bucal

La cavidad bucal contiene los dientes, lengua, paladar y otras estructuras. Los dientes ayudan a triturar los alimentos mediante la masticación. La lengua participa en la masticación, habla y degustación. Las glándulas salivales, como las parótidas y submandibulares, segregan saliva para humedecer la boca y comenzar la digestión de carbohidratos.

Compil africa twin

The document discusses the benefits of exercise for mental health. Regular physical activity can help reduce anxiety and depression and improve mood and cognitive function. Exercise causes chemical changes in the brain that may help protect against mental illness and improve symptoms for those who already suffer from conditions like anxiety and depression.

OEE CALCULATION PPT

This document provides an introduction to Overall Equipment Effectiveness (OEE) including definitions of key terms and calculations. It discusses the six big losses that reduce productivity, and how OEE is calculated based on availability, performance, and quality. An example calculation is shown to demonstrate how OEE, availability, performance, and quality are determined based on production data. Finally, it compares the calculated OEE to world class benchmarks.

Overall Equipment Effectiveness

The document discusses overall equipment effectiveness (OEE) and its calculation. It defines OEE as the product of availability, performance, and quality. Availability accounts for downtime losses. Performance considers speed losses. Quality looks at good units produced. The document provides an example calculation of OEE for a machine with a 77.4% effectiveness rate. It also modifies the OEE calculation to include usability which accounts for stop time losses.

Ricebanoil

This document summarizes a senior project to design a rice bran oil extraction system. A team developed a screw press design to extract 10-18% oil from rice bran. Testing showed extraction rates of 6.9-9.4% oil and 3 gallons of oil extracted per week. Recommendations include improvements to increase extraction rates and optimize the system for easier cleaning and maintenance in compliance with safety standards. Funding was provided by Lundberg Family Farms, CSU AS Sustainability, and the Center for Entrepreneurship.

Production & Operarions Management Compre Review

Production & Operations Management

Comprehensive Exam Review

February 8, 2015

San Beda College Graduate School of Business

Combined Pat Presentation Oct - Copy

This document provides updates on several current Process Action Team (PAT) projects at the company:

- Change Overs, PM Completion, Identify Safety Hazards, and Mentoring Program PATs are tracking metrics and goals.

- Quickie Rinse, Bulgar Wheat Reduction, and 50/50 Oil Reduction PATs are testing ideas to reduce time and waste.

- Temp Training, Marsh Printer errors, and Bulk Management PATs are monitoring issues around temps, printer errors, and bulk waste. Old PATs will close and resources move to new projects.

Food waste and food processing waste for renewable energy production

Full proceedings at: http://www.extension.org/72790 This high efficient and low-cost eggshell catalyst could make the process of biodiesel production economic and fully ecologically friendly. The ecologically friendly and economic process could effectively reduce the processing cost of biodiesel, making it competitive with petroleum diesel.

Industrial Engineering Training

This document discusses key concepts related to production line management including:

Standard minute value (SMV) which represents the average time for a worker to complete a task including allowances. Target calculation uses SMV to determine production goals.

Line balancing aims to match production rate to takt time by balancing operator and machine times.

A bottleneck refers to the lowest output point in the production line.

Other topics covered include line feeding activities from pre-setting to monitoring production, and how to address issues like re-balancing the line and improving efficiency over time.

Litttle knowledge of lean concept helps

The document discusses measuring manufacturing cycle efficiency through calculating manufacturing cycle efficiency (MCE). MCE is defined as the value added time divided by the total cycle time. It provides two examples to demonstrate how MCE can be calculated and used to track process improvements over time. The document also discusses using takt time as a meaningful measurement gauge to ensure customer demand is met. Takt time is defined as the total available time divided by customer demand. Using takt time, the expected cycle time for each process can be calculated to meet production goals.

Oee and its Application

OEE Description

OEE is the way to Measure Effectiveness

OEE, its Application, 16 major losses, 8 equipment loses

OEE= Availability x Performance x Quality Availability

session 1

The document discusses cost reduction techniques. It covers topics like the benefits of cost reduction, the 6Ms of cost (machine, manpower, material, methods, money, space), why cost reduction is important at the operational level, and how cost reduction can impact profits. Workshops are proposed to teach tools like Ishikawa diagram and exercises are suggested to maximize utilization and reduce product costs. Feedback is collected at the end to evaluate the workshops.

Production Schedule Report 2016-rv

This document contains a weekly production schedule for a manufacturing plant over five days from Monday to Friday. It includes planned versus actual production hours and output for different production lines and shifts. Several key performance metrics like overall equipment effectiveness (OEE) are reported. Production was highest on the Monday day shift, achieving an OEE of 105.56%, and lowest on Wednesday with no recorded output.

OEE IMPLEMENTATION part 1

OEE definition and how to Implementation Of OEE as monitoring to Know How Performance, Availability and Quality

More Related Content

Viewers also liked

Clearpath-Partnerships

Clearpath Solutions Group is an IT solutions provider that partners with technology leaders to customize solutions for storage, compute, backup/disaster recovery, networking, security, virtual desktops, and collaboration. They offer consulting, managed cloud services, and help manage IT budgets. Contact them at solutions@clearpathsg.com for assistance.

Top 10 Reasons Your CRF May Not Have Performed As Expected Final

1. Not accounting for the fertilizer and media displaced when transferring plants to larger containers can result in a lower fertilizer dose and shorter longevity.

2. Choosing a CRF longevity that is too short or long may cause slow growth - it should provide proper nutrition throughout the crop cycle.

3. The only way to find the best CRF formulation is through trialing under your own growing conditions since practices vary.

Metlityudi

The document summarizes a report on the structural material considerations for the first graving dock built in St. John's, Newfoundland in 1882. It discusses how a wooden design was chosen over stone after a thorough investigation by J.J. Little who visited dry docks in several American cities. Little's report favored wood based on shorter construction time, lower costs, and opinions he collected that said wood docks were more durable and effective than stone docks in cold climates. As a result, the Newfoundland government decided to use wood for the first graving dock in St. John's harbor.

RSB Henneke PD Training Program 031816

The document provides information about a Rock Steady Boxing program for people with Parkinson's disease offered at Title Boxing Club. It summarizes the instructor Kane Henneke's qualifications and experience in martial arts. It outlines the typical class format, which includes conditioning, drills, and techniques. Students progress through a graduated degree program involving different techniques as they test for new belt levels. The club promises a safe, diverse martial arts experience and satisfaction for students and families.

6072 18609-1-sm

O documento discute a simulação numérica e o método de experimentos planejados (DOE) aplicados para melhorar o processo de fundição sob pressão de ligas de alumínio. Inicialmente, simulações foram realizadas para identificar as causas de porosidade em uma peça. Em seguida, um DOE foi usado variando parâmetros de injeção para avaliar sua influência na qualidade da peça. Resultados experimentais selecionados foram simulados numericamente para comparação.

Emotions Modelling and Synthetic Characters

Dr. Aladdin Ayesh presents on emotions modelling and synthetic characters. He discusses some key issues in emotions modelling like selecting emotions to represent, expressing emotions, and recognizing emotions from facial expressions and other cues. He outlines some of his research projects in this area, including computational models of emotion and emotionally expressive communication languages.

Región bucal

La cavidad bucal contiene los dientes, lengua, paladar y otras estructuras. Los dientes ayudan a triturar los alimentos mediante la masticación. La lengua participa en la masticación, habla y degustación. Las glándulas salivales, como las parótidas y submandibulares, segregan saliva para humedecer la boca y comenzar la digestión de carbohidratos.

Compil africa twin

The document discusses the benefits of exercise for mental health. Regular physical activity can help reduce anxiety and depression and improve mood and cognitive function. Exercise causes chemical changes in the brain that may help protect against mental illness and improve symptoms for those who already suffer from conditions like anxiety and depression.

Viewers also liked (10)

Top 10 Reasons Your CRF May Not Have Performed As Expected Final

Top 10 Reasons Your CRF May Not Have Performed As Expected Final

Similar to Data Processing

OEE CALCULATION PPT

This document provides an introduction to Overall Equipment Effectiveness (OEE) including definitions of key terms and calculations. It discusses the six big losses that reduce productivity, and how OEE is calculated based on availability, performance, and quality. An example calculation is shown to demonstrate how OEE, availability, performance, and quality are determined based on production data. Finally, it compares the calculated OEE to world class benchmarks.

Overall Equipment Effectiveness

The document discusses overall equipment effectiveness (OEE) and its calculation. It defines OEE as the product of availability, performance, and quality. Availability accounts for downtime losses. Performance considers speed losses. Quality looks at good units produced. The document provides an example calculation of OEE for a machine with a 77.4% effectiveness rate. It also modifies the OEE calculation to include usability which accounts for stop time losses.

Ricebanoil

This document summarizes a senior project to design a rice bran oil extraction system. A team developed a screw press design to extract 10-18% oil from rice bran. Testing showed extraction rates of 6.9-9.4% oil and 3 gallons of oil extracted per week. Recommendations include improvements to increase extraction rates and optimize the system for easier cleaning and maintenance in compliance with safety standards. Funding was provided by Lundberg Family Farms, CSU AS Sustainability, and the Center for Entrepreneurship.

Production & Operarions Management Compre Review

Production & Operations Management

Comprehensive Exam Review

February 8, 2015

San Beda College Graduate School of Business

Combined Pat Presentation Oct - Copy

This document provides updates on several current Process Action Team (PAT) projects at the company:

- Change Overs, PM Completion, Identify Safety Hazards, and Mentoring Program PATs are tracking metrics and goals.

- Quickie Rinse, Bulgar Wheat Reduction, and 50/50 Oil Reduction PATs are testing ideas to reduce time and waste.

- Temp Training, Marsh Printer errors, and Bulk Management PATs are monitoring issues around temps, printer errors, and bulk waste. Old PATs will close and resources move to new projects.

Food waste and food processing waste for renewable energy production

Full proceedings at: http://www.extension.org/72790 This high efficient and low-cost eggshell catalyst could make the process of biodiesel production economic and fully ecologically friendly. The ecologically friendly and economic process could effectively reduce the processing cost of biodiesel, making it competitive with petroleum diesel.

Industrial Engineering Training

This document discusses key concepts related to production line management including:

Standard minute value (SMV) which represents the average time for a worker to complete a task including allowances. Target calculation uses SMV to determine production goals.

Line balancing aims to match production rate to takt time by balancing operator and machine times.

A bottleneck refers to the lowest output point in the production line.

Other topics covered include line feeding activities from pre-setting to monitoring production, and how to address issues like re-balancing the line and improving efficiency over time.

Litttle knowledge of lean concept helps

The document discusses measuring manufacturing cycle efficiency through calculating manufacturing cycle efficiency (MCE). MCE is defined as the value added time divided by the total cycle time. It provides two examples to demonstrate how MCE can be calculated and used to track process improvements over time. The document also discusses using takt time as a meaningful measurement gauge to ensure customer demand is met. Takt time is defined as the total available time divided by customer demand. Using takt time, the expected cycle time for each process can be calculated to meet production goals.

Oee and its Application

OEE Description

OEE is the way to Measure Effectiveness

OEE, its Application, 16 major losses, 8 equipment loses

OEE= Availability x Performance x Quality Availability

session 1

The document discusses cost reduction techniques. It covers topics like the benefits of cost reduction, the 6Ms of cost (machine, manpower, material, methods, money, space), why cost reduction is important at the operational level, and how cost reduction can impact profits. Workshops are proposed to teach tools like Ishikawa diagram and exercises are suggested to maximize utilization and reduce product costs. Feedback is collected at the end to evaluate the workshops.

Production Schedule Report 2016-rv

This document contains a weekly production schedule for a manufacturing plant over five days from Monday to Friday. It includes planned versus actual production hours and output for different production lines and shifts. Several key performance metrics like overall equipment effectiveness (OEE) are reported. Production was highest on the Monday day shift, achieving an OEE of 105.56%, and lowest on Wednesday with no recorded output.

OEE IMPLEMENTATION part 1

OEE definition and how to Implementation Of OEE as monitoring to Know How Performance, Availability and Quality

Precision agriculture

This is the second presentation I was invited to give at the CAVI conference held in Galway, Ireland on October 12. it deals with precision dairy farming. A field that is coming up and growing in importance in modern dairy farming

MRM April 2015 ufl

The document provides quality and production metrics for different production lines from July 2014 to June 2015. Some key metrics reported include:

- Customer rejection rates have decreased but remain above target levels. Internal rejection and rework rates have also improved but remain higher than best-in-industry levels.

- Production efficiency rates for most lines are around 80% on average but below targets. On-time production rates are also mostly below targets.

- 5S audit scores and preventative maintenance targets are mostly met across lines, but some expenditure targets were missed.

- A total of 40 kaizen proposals were submitted through March 2015 and all were approved with no pending proposals.

Technical and organizational optimization of the product freezing in a meat p...

Technical and organizational optimization of the product freezing in a meat p...Enrique Cabrera Cano

The extra cost of decreasing the initial temperature of 17,239.6 kg of bacon from 3°C to 1°C using a conventional refrigeration system would be 11.35€.13 b shukla

The document discusses cogeneration applications in sugar mills. Cogeneration, or combined heat and power (CHP), involves producing electricity and useful thermal energy from a single fuel source. This is more efficient than separate generation of power and heat. The document provides details on existing cogeneration systems in sugar mills and recommendations for improving efficiency through retrofitting high-pressure boilers, installing topping cycles, and acquiring best available technologies for new projects. Case studies show potential savings from reducing downtime and power consumption.

UKTI Australia Renewables Webinar

Presentation by Alex Marshall delivered at the UKTI Renewables Webinar on the 30th May 2013. This presentation includes an outline of cogeneration technology, the benefits of embedded generation and renewable technologies including biogas, landfill gas and sewage gas to power.

Lab 3 boiler efficiency & condensers

CAPE PENINSULA UNIVERSITY OF TECHONOLOGY

DEPARTMENT OF MECHANICAL ENGINEERING

THERMODYNAMICS 2

LAB

Productivity improvement & waste reduction

This document summarizes a project to reduce shell weight for BH521 6-cavity shells from 27kg to 25kg while maintaining low defect rates. Key actions included measuring current weights, analyzing factors like investment time and temperature, conducting experiments to optimize parameters, implementing controls at 65-70s and 240°C, and verifying the new process achieved an average weight of 25.5kg. Savings of 1.4kg resin per shell and an extra shell per hour were projected to yield annual savings of Rs. 5.88 lakhs. Controls were established for materials, times, and temperatures to sustain the improvement.

Lean Energy

Energy management journey at Volvo Construction Equipment starting with idle electricity and expanding to energy savings and renewable energy

Similar to Data Processing (20)

Food waste and food processing waste for renewable energy production

Food waste and food processing waste for renewable energy production

Technical and organizational optimization of the product freezing in a meat p...

Technical and organizational optimization of the product freezing in a meat p...

Data Processing

- 1. Production Data Shift Length 12 Hours = 720 Minutes Short Breaks 1 Breaks @ 25 Minutes Each = 25 Minutes Total Meal Break 1 Breaks @ 30 Minutes Each = 30 Minutes Total Down Time 120 Minutes Ideal Run Rate 176.39 Real Run Rate 126.06 Total production 68700 kg Reject production 5100 kg planned production 117300 kg Support Variable Calculation Result Planned Production Time Shift Length - Breaks 665 Minutes Operating Time Planned Production Time - Down Time 545 Minutes Good production 63600 kg OEE Factor Calculation My OEE% Availability Operating Time / Planned Production Time 81.95 Performance (Total Production / Operation Time) / Ideal Run Rate 71.46 Quality Good Production / Total Production 92.58 Overall OEE Availability x Performance x Quality 54.22 OEE Factor World Class My OEE% Factor / Date Availability Performance Quality Availability 90.00% 81.95 91/02/30 85.71 78.36 91.91 Performance 95.00% 71.46 91/02/31 81.95 71.46 92.58 Quality 99.90% 92.58 Average 83.83 74.91 92.25 Overall OEE 85.00% 54.22 weeks First Second Third Fourth Fifth OEE 62.52% 55.32% 61.12% 58.00% 57.93% weight 6 6 6 6 2 Straight Average 58.98% 59.14Weighted Average planned production / planned production time ( Kg Per Minute ) Total Production - Reject Production Total production / Operating Time ( Kg Per Minute ) OEE_ END Week 57.93