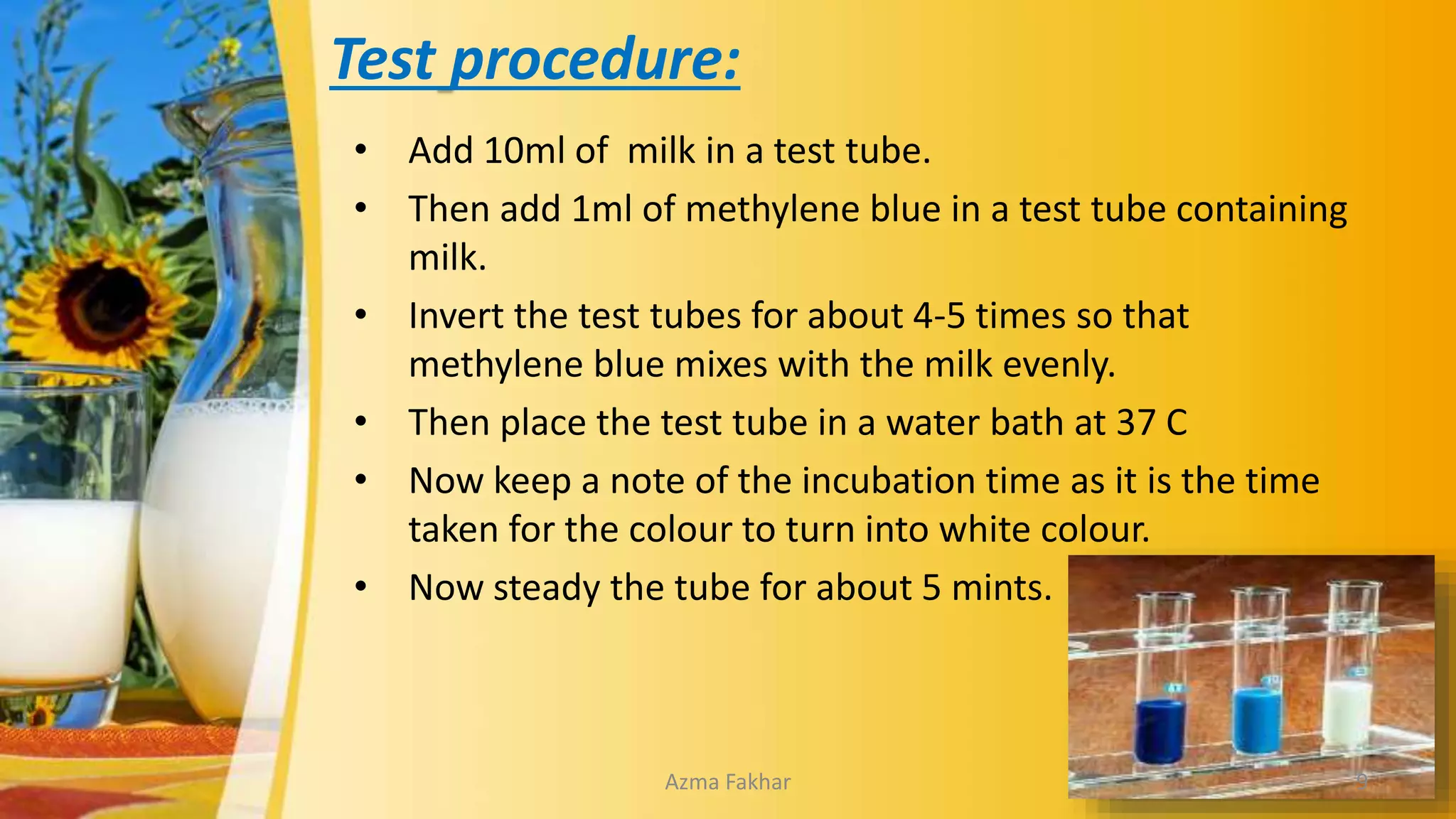

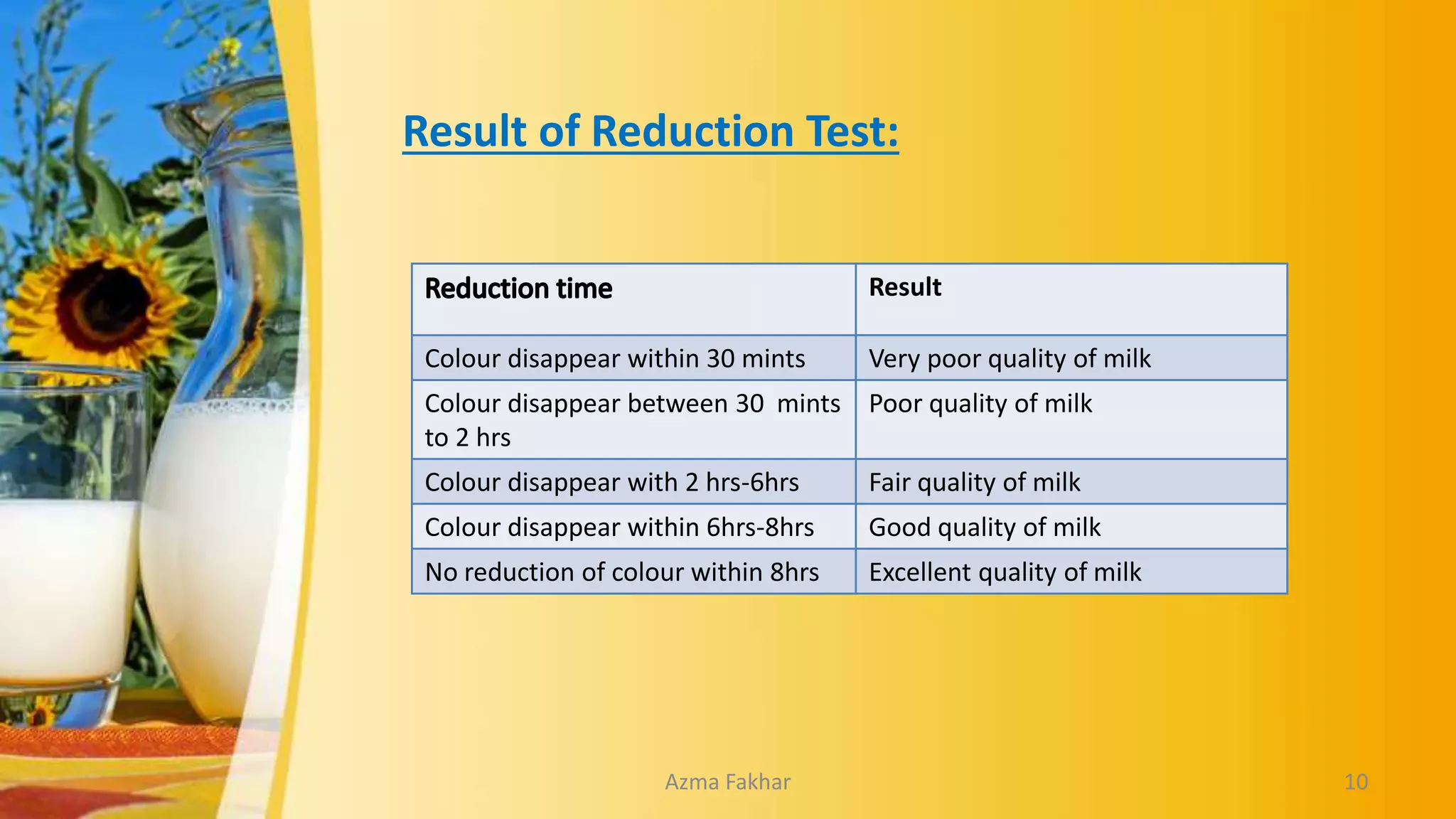

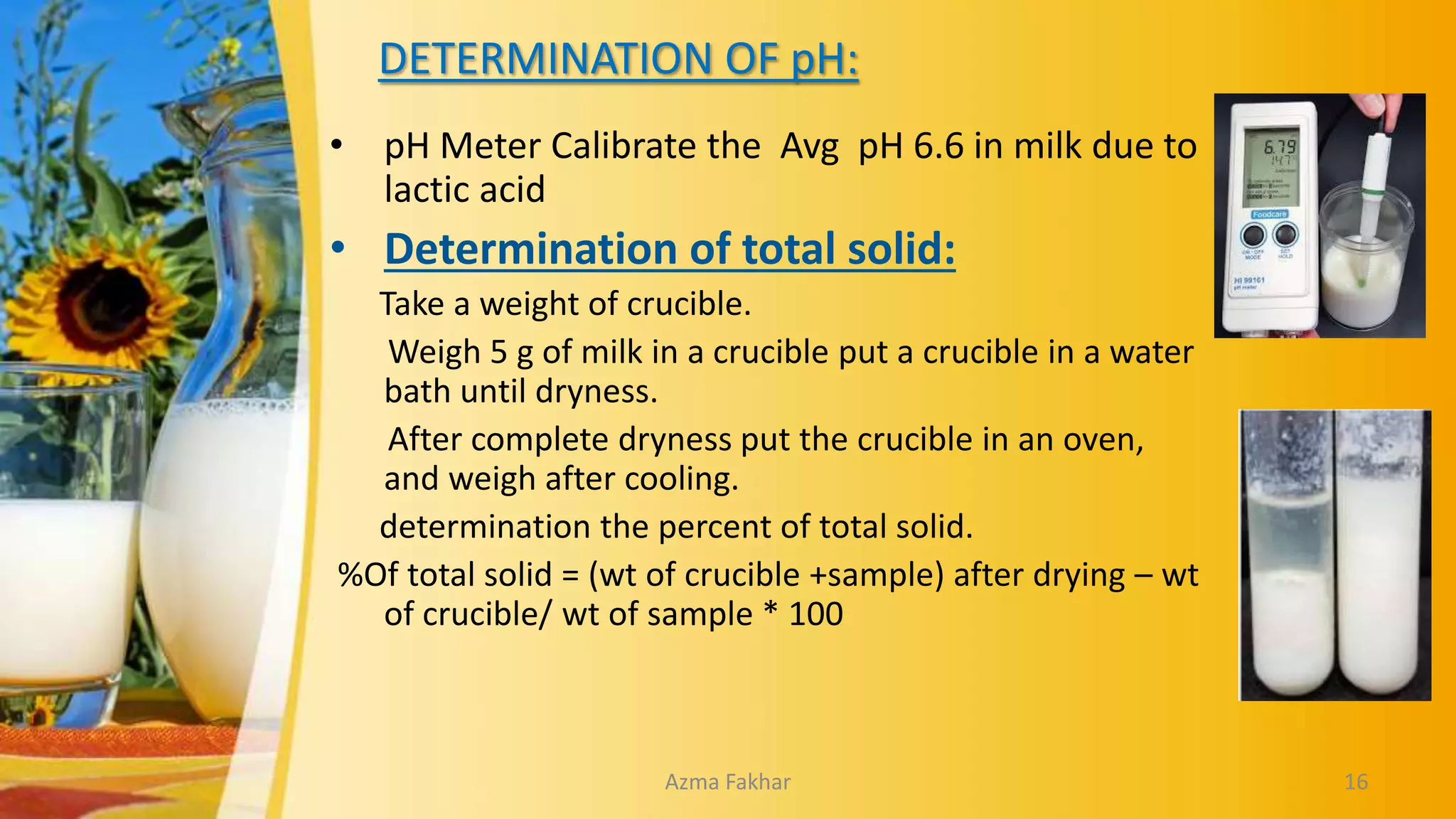

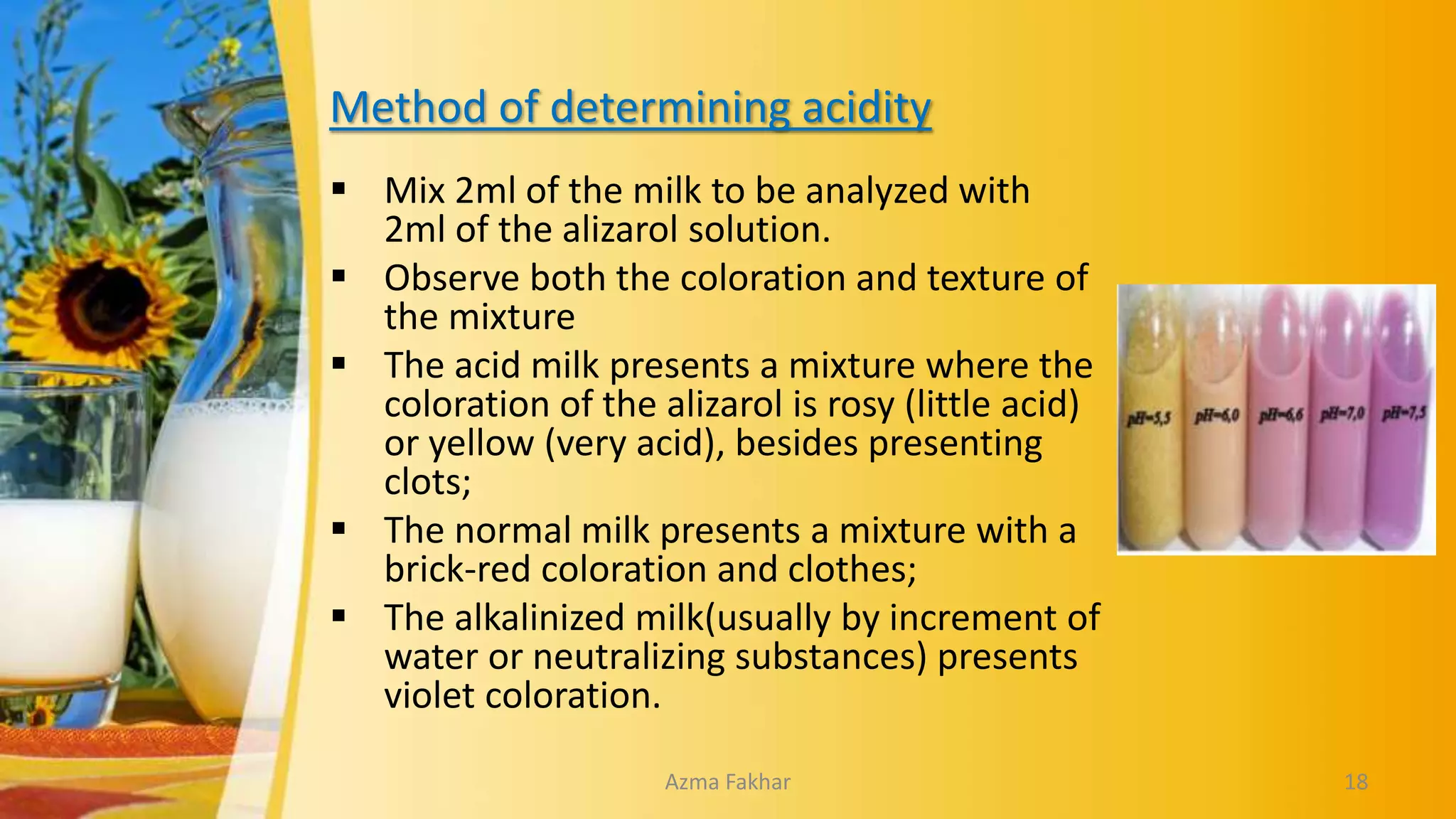

This document discusses the analysis of milk and butter. It outlines various tests that can be performed on milk, including tests to determine density, fat content, total dry extract, acidity, and microbiological quality. The preparation of milk samples is also described. For butter analysis, tests are discussed to determine chemical composition, color, acidity, rancidity, and microbial quality over various storage periods. The goal of these analyses is to ensure the quality of both milk and butter products.