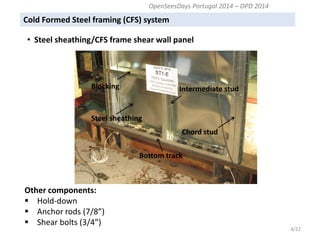

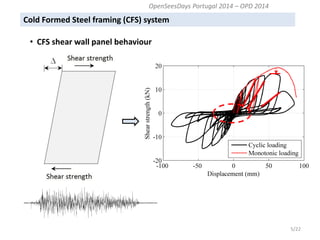

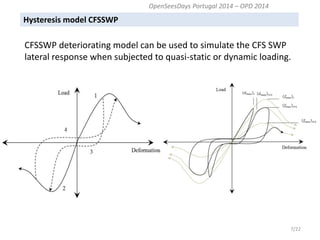

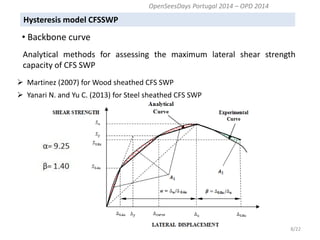

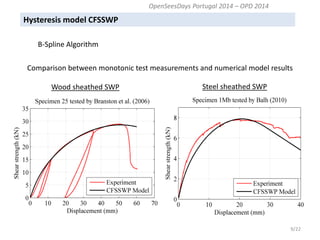

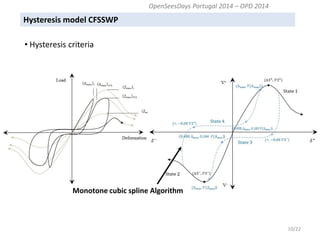

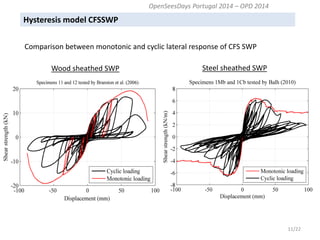

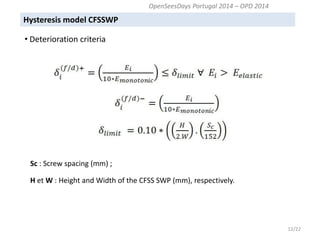

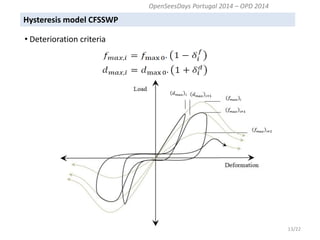

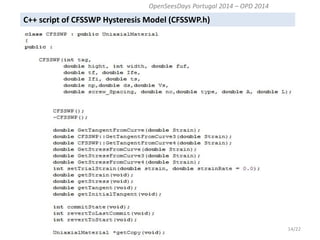

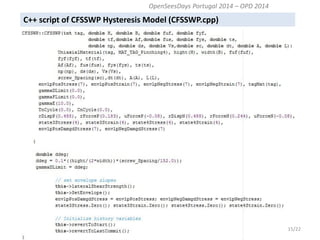

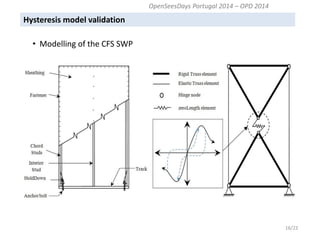

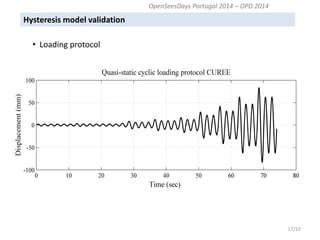

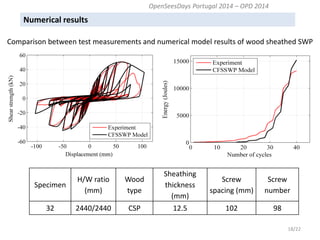

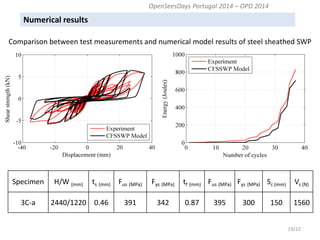

This document presents the development of a deteriorating hysteresis model for cold-formed steel shear wall panels (CFS SWP) based on their physical and mechanical characteristics. The model has been implemented in the Opensees software and validated against experimental results, demonstrating good correlation in shear strength and energy dissipation. Key findings include successful integration of the model as a user-defined material in C++ and its applicability in simulating lateral response under various loading conditions.