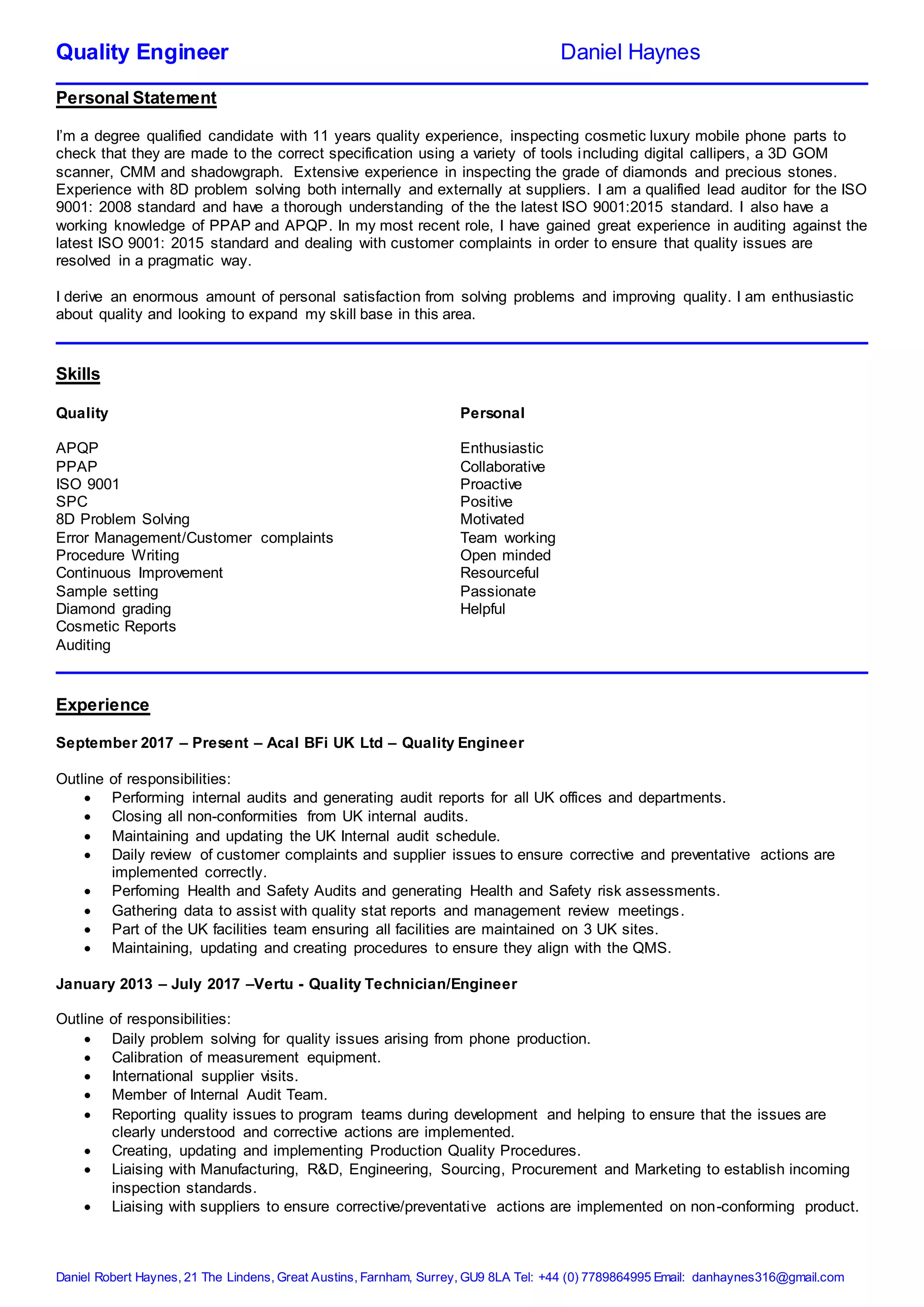

Daniel Haynes is a quality engineer with 11 years of experience in inspecting luxury mobile phone parts and diamonds, as well as expertise in ISO standards and 8D problem solving. He has held roles at Acal BFI UK Ltd and Vertu, focusing on internal audits, customer complaint resolution, and quality procedure development. Haynes is looking to expand his skills in quality management and aims to progress toward a quality management position in the next three to five years.