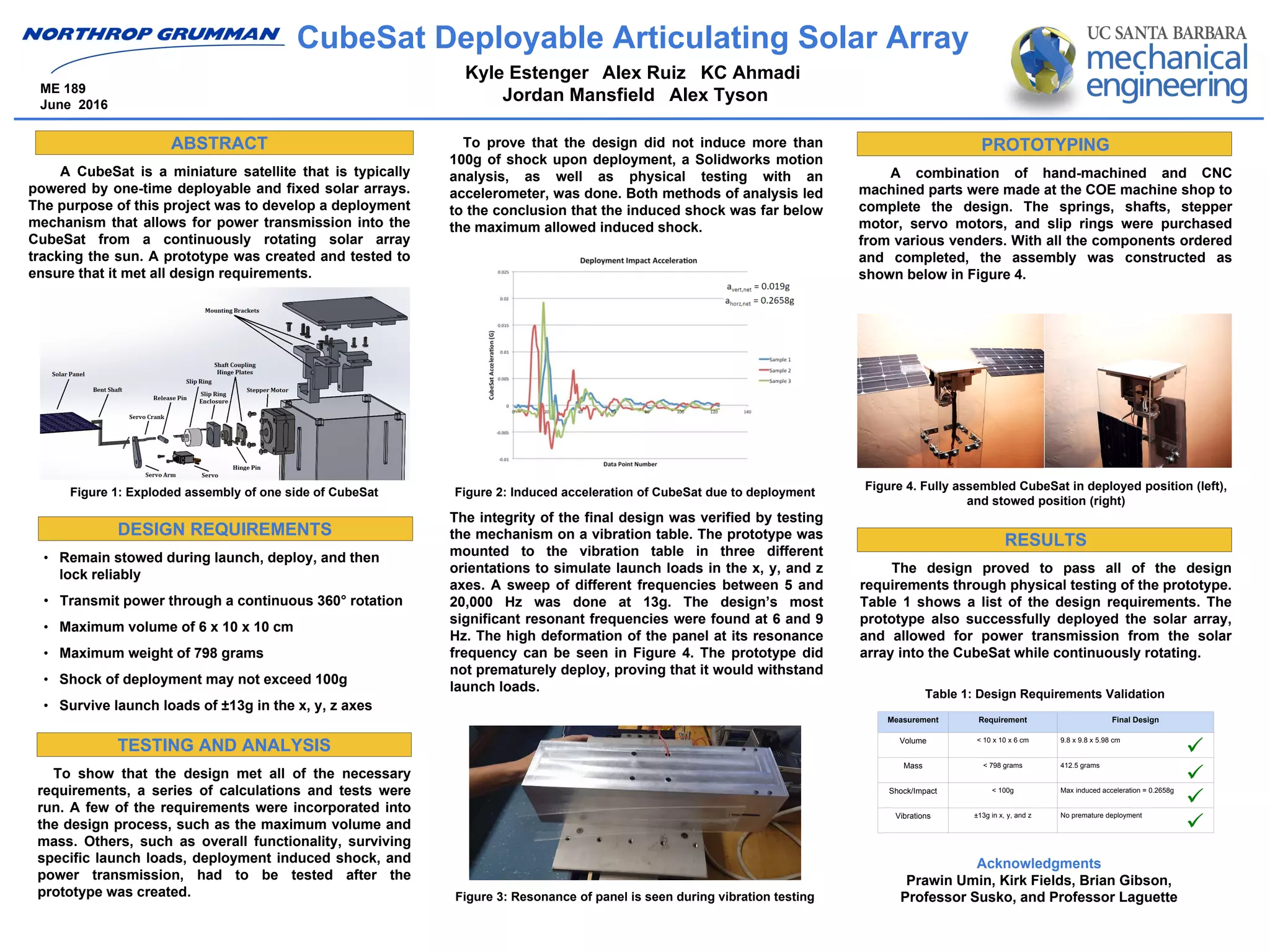

This document describes the design, prototyping, testing, and results of a deployable articulating solar array for CubeSats. The key requirements were to remain stowed during launch and deploy reliably while transmitting power through continuous 360 degree rotation within a volume of 6x10x10 cm and weight of 798 grams, and surviving launch loads and a shock of deployment not exceeding 100g. A prototype was built and tested through vibration, motion analysis, and acceleration measurements to verify all requirements were met, including deploying the array and allowing power transmission during rotation.