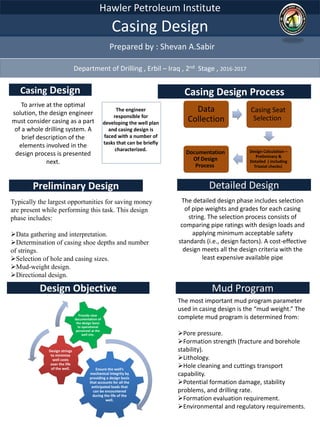

The document discusses the casing design process for oil and gas wells. It notes that the design engineer must consider casing as part of the overall drilling system. The casing design process involves: 1) collecting data on anticipated loads and well conditions over the life of the well to ensure mechanical integrity; 2) designing casing strings to minimize total well costs; and 3) providing clear documentation of the design basis for operational personnel. The detailed design phase includes selecting pipe weights and grades for each casing string based on design loads and safety standards.