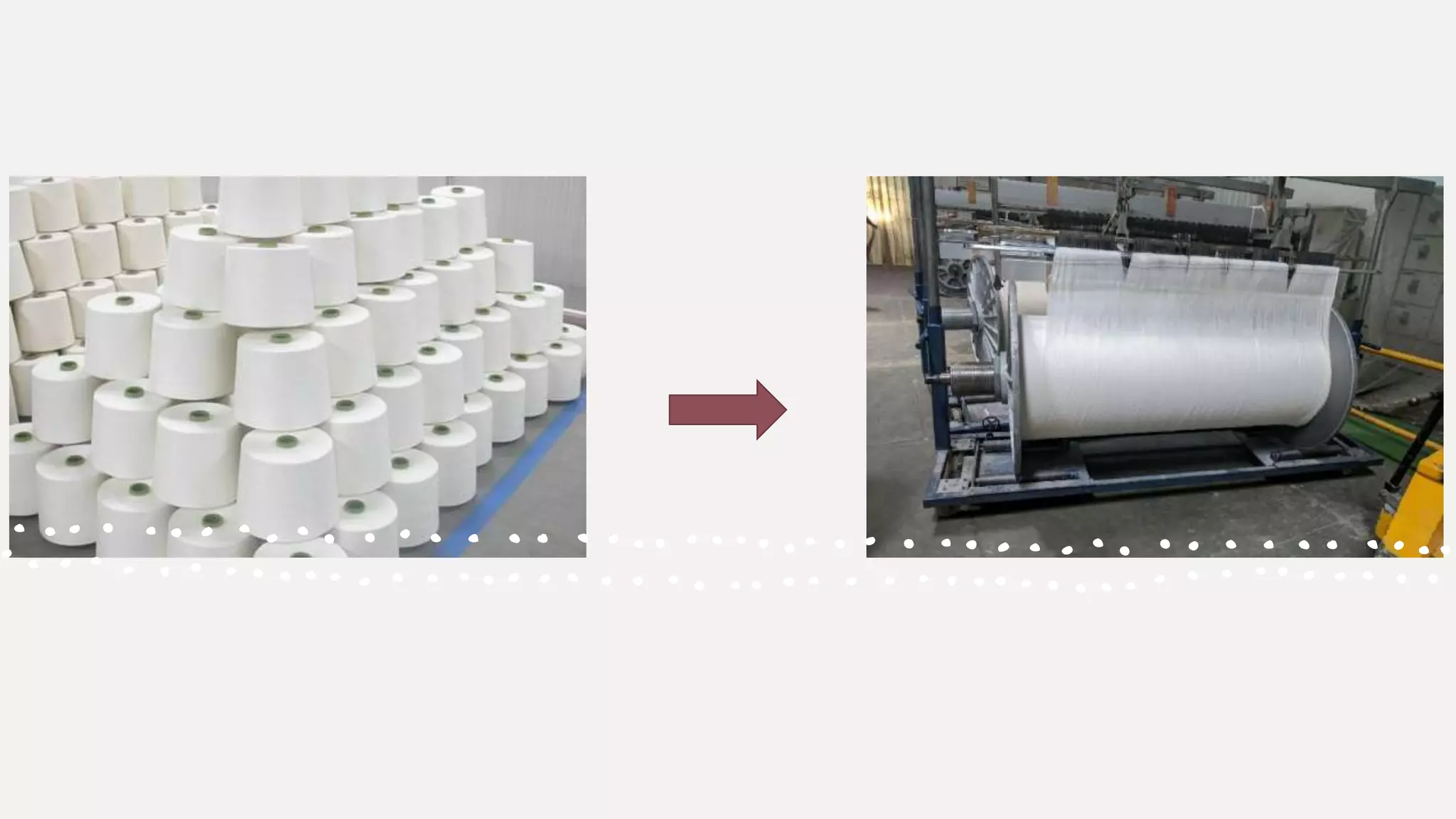

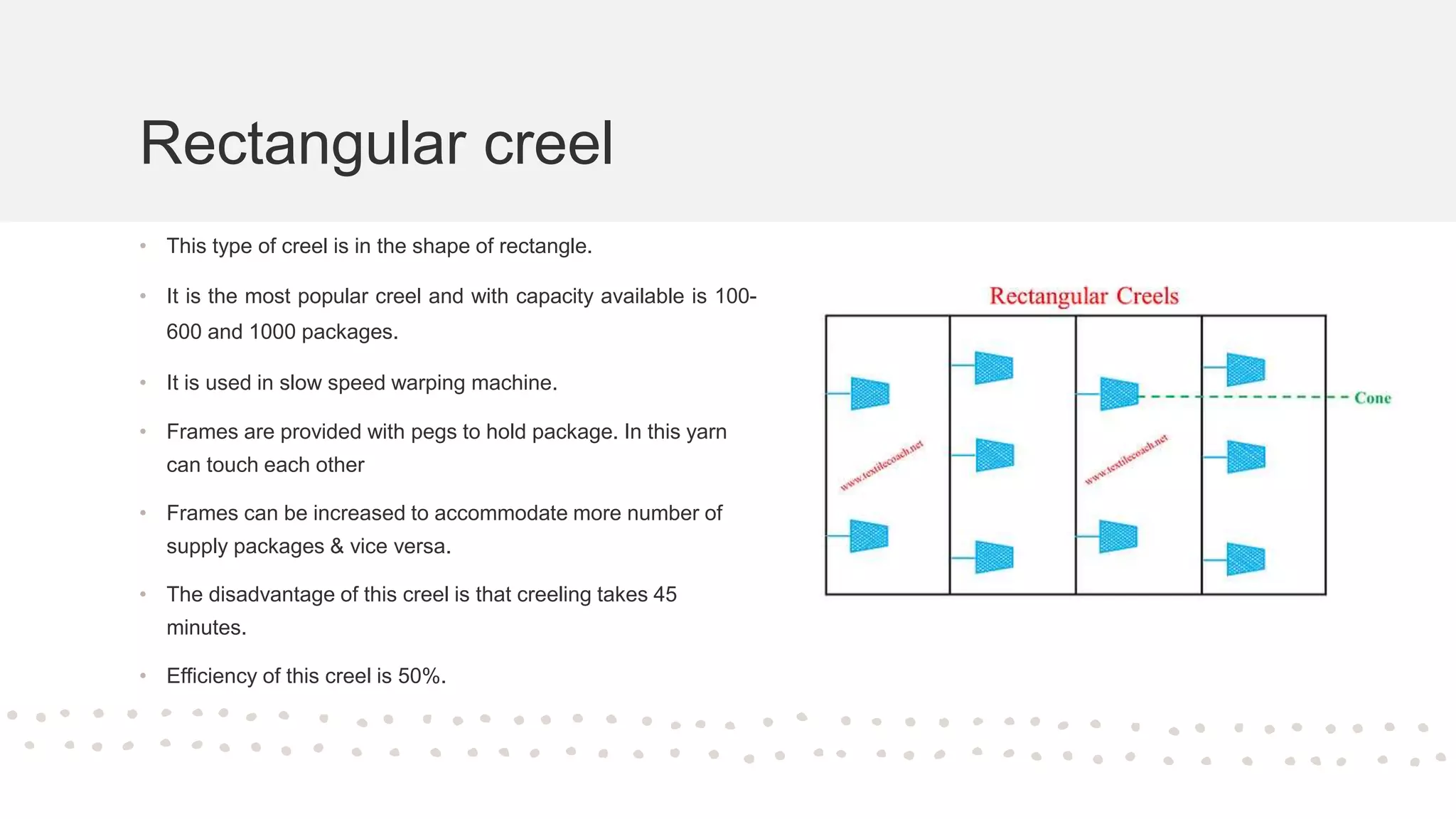

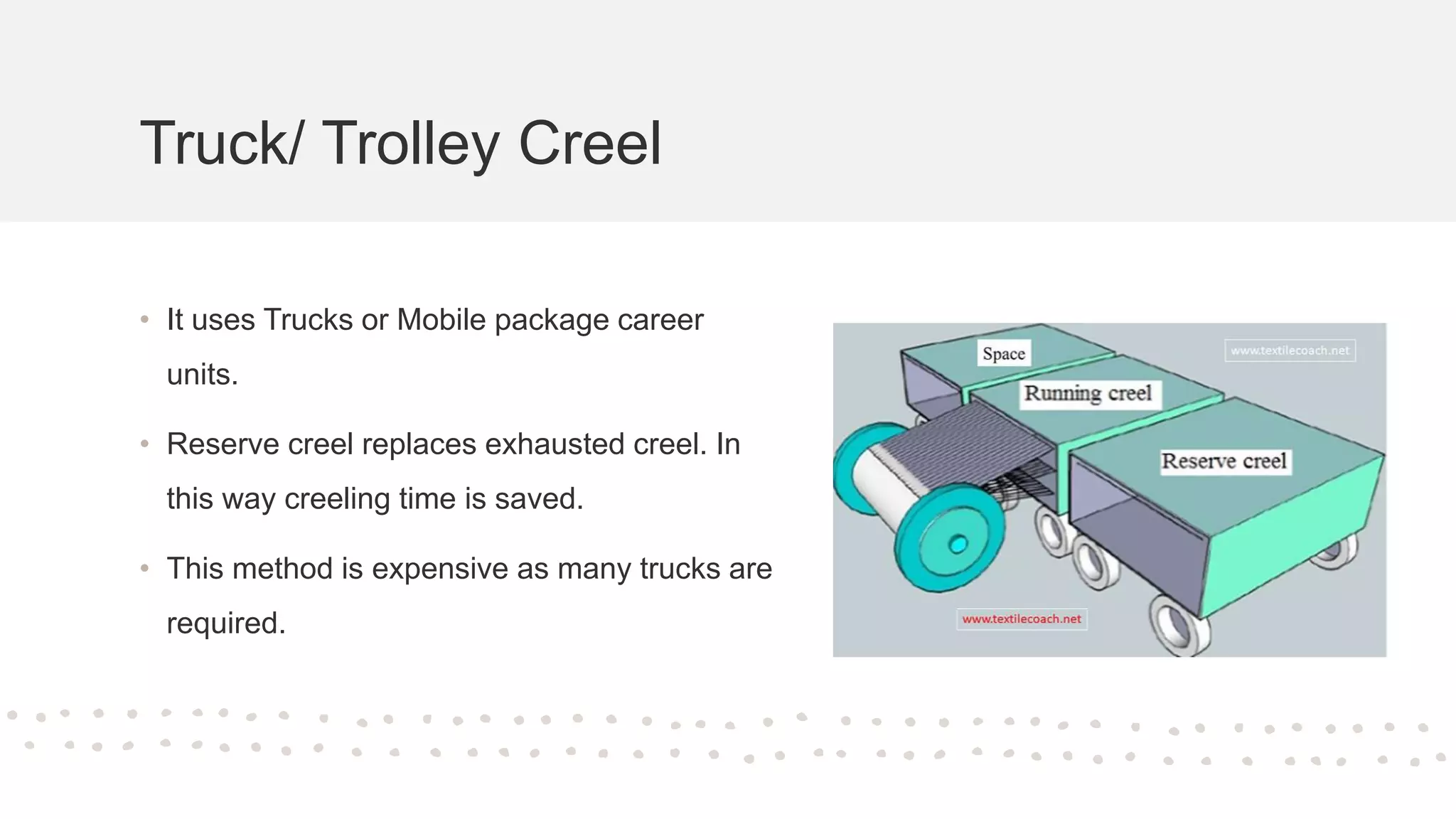

This document discusses different types of creels used in textile warping processes. A creel is a frame that holds the supply packages of yarn. It enables the yarn to be held in the proper position for warping. The main types discussed are V-creel, rectangular creel, unrolling creel, truck/trolley creel, automatic creel, swivel frame creel, continuous chain creel, and magazine creel. Each type has different features in terms of capacity, efficiency, and ability to replace packages automatically. Creels are an important component for maintaining uniform tension and guiding the yarn in the warping process.